Cover Page

The Project Gutenberg EBook of The Boy Craftsman, by A. Neely Hall

This eBook is for the use of anyone anywhere at no cost and with

almost no restrictions whatsoever. You may copy it, give it away or

re-use it under the terms of the Project Gutenberg License included

with this eBook or online at www.gutenberg.org

Title: The Boy Craftsman

Practical and Profitable Ideas for a Boy's Leisure Hours

Author: A. Neely Hall

Illustrator: Norman P. Hall

Release Date: May 5, 2013 [EBook #42650]

Language: English

Character set encoding: ISO-8859-1

*** START OF THIS PROJECT GUTENBERG EBOOK THE BOY CRAFTSMAN ***

Produced by Chris Curnow, Brian Wilcox and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by The Internet Archive)

Cover Page

HANDICRAFT BOOKS

BY

A. NEELY HALL

8vo. Cloth. Illustrated with hundreds of photographs

and working drawings by the author

and Norman P. Hall

THE BOY CRAFTSMAN

HANDICRAFT FOR HANDY BOYS (Revised Edition)

THE HANDY BOY (Revised Edition)

HOME-MADE TOYS FOR GIRLS AND BOYS

HANDICRAFT FOR HANDY GIRLS

CARPENTRY AND MECHANICS FOR BOYS

HOME-MADE GAMES AND GAME EQUIPMENT

(Revised Edition)

OUTDOOR BOY CRAFTSMEN

BIG BOOK OF BOYS' HOBBIES

LOTHROP, LEE & SHEPARD COMPANY

BOSTON NEW YORK

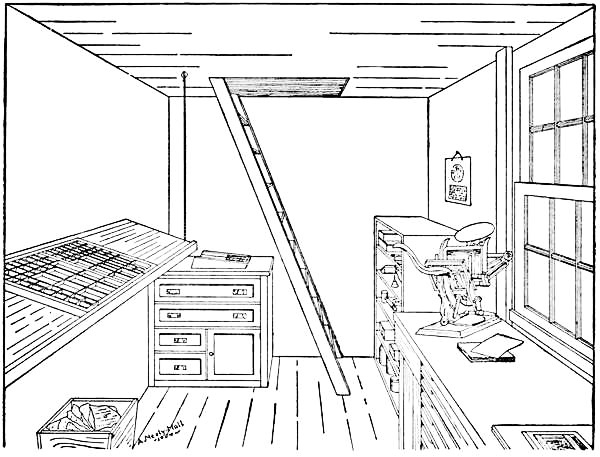

A Boy's Workshop.

THE BOY

CRAFTSMAN

Practical and Profitable Ideas

for a Boy's Leisure Hours

BY

A. Neely Hall

With more than four hundred illustrations

by the author and Norman P. Hall

BOSTON

LOTHROP, LEE & SHEPARD CO.

Copyright, 1905, by Lothrop, Lee & Shepard Company.

Published, August, 1905.

All rights reserved.

The Boy Craftsman.

Norwood Press

J. S. Cushing & Co.—Berwick & Smith Co.

Norwood, Mass., U.S.A.

—Theodore Roosevelt.

The boy of to-day is ever on the lookout for new ideas which can be adopted for his work and recreation, schemes which are practical and which are thoroughly up-to-date. They must be helpful in suggesting ways of earning money, as well as entertaining, for what boy of the present day does not feel the need of such suggestions to aid him in raising the funds necessary to carry on his work?

In none of the books published on boy's handicraft has the question entered into consideration as to how he is to obtain the means with which to buy such materials and apparatus as the work requires. A boy should not expect to draw upon his father's purse for everything his fancy desires. It is important that he learn to earn his spending money, for in doing so he becomes independent and more careful as to how he invests it. Having had the experience of working, the average boy learns to so appreciate the value of hard-earned money that it is pretty certain he will spend it only for something with which he can earn more or which will prove useful to him in his work and play.

"The Boy Craftsman" has been undertaken with a view of helping boys with their problems of earning money, as well as furnishing recreative and entertaining work, and to this end the first portion has been devoted to suggestions for the carrying on of a number of small business enterprises, and the second [Pg iv] and third parts to outdoor and indoor pastimes for all seasons of the year.

In "Profitable Pastimes" a boy will find work that will make easy the matter of earning money with which to buy such materials as he needs to carry out the suggestions offered in the book, while the practical knowledge acquired and the handiness developed in pursuing the several lines of work is certain to be helpful to him in later years.

The tools and apparatus used are such as a boy of average ability can procure with a little hustling, and can be purchased singly, or two or three at a time, as his money permits. The materials at hand can be used in thousands of different ways, and in preparing the chapters this has been taken into consideration, these odds and ends being utilized whenever it has been possible to do so.

Carpenter work is something with which every boy must familiarize himself to a certain extent in order to do anything in the line of construction, so the fitting up of a workshop and the proper handling of tools have been described in the first two chapters, in view of making it a simple matter to perform the work embodied in the rest of the book.

Technical terms and phrases have been eliminated from the text as far as possible, and where it has been deemed necessary to include them, to describe certain operations for which a boy should know the proper terms or expressions, they have generally been explained in the first chapter in which they occur. To simplify the matter of referring to the definitions of these, they have been arranged alphabetically in Chapter XXIX.

Some of the material contained in this book was originally written by the author in the form of magazine articles for The American Boy and The Boys' World, and thanks are due the[Pg v] publishers, The Sprague Publishing Company and The David C. Cook Publishing Company, for permission to reprint it. This material has been revised and enlarged upon, and is presented with new and additional illustrations.

The author is always glad to hear from his young readers, and to be of assistance to them in answering any questions they wish to ask regarding their work.

A. N. H.

Chicago, Illinois,

May 31, 1905.

PART I

PROFITABLE PASTIMES

CHAPTER I

PAGE

A Boy's Workshop3

Value of a Knowledge of Carpenter Work—Location of Shop—A Solid Work-bench—The Vise—Bench-stops—Carpenter's Horses—A Bench-hook—A Mitre-box—A Sand-paper Block—A Strop—A Plumb—Purchasing Tools—Tool-cabinets—Racks for Tools—A Carpenter's Carrying-box—A Nail-box—Receptacles for Supplies—Workshop Clothes—Care of Oily Rags and Waste.

CHAPTER II

The Proper Handling of Tools20

Care of Tools—The Cross-cut Saw and Rip-saw—Sawing—The Back-saw, Compass-saw, and Gig-saw—Kerfs—The Jack-plane, Fore-plane, and Smoothing-plane—Planing—Testing Work—The Firmer-chisel—Paring—The Framing-chisel—Chamfering and Bevelling—The Gouge—The Draw-knife—Boring—An Automatic-drill—Hatchet and Hammer—Driving Nails—Withdrawing Nails—Toe-nailing—Blind-nailing—Clinching—The Nail-set—Nails—Screw-driver for Bit-stock—Screws—The Countersink.

[Pg viii]Sharpening Tools37

Grinding Chisels, Gouges, Draw-knives, Knives and Hatchets—The Washita Oil-stone—Whetting—Stropping—Sharpening Saws.

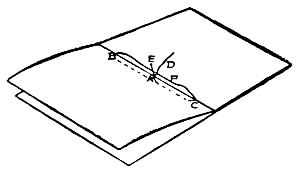

Laying out Work42

Use of the Try-square—Gauging with Rule and Pencil—A Marking-gauge—A Mitred Try-square—The Bevel—To Divide a Board.

CHAPTER III

The Boy about the House47

Opportunities for Work—Outfit for Jobbing—The Hinge-lock—Clothes-line Reel—A Broom and Dust-pan Rack—The Fly-killer—An Ash-sifter—A Bread-board—A Plate-rack

CHAPTER IV

Suggestions for a Boy's Room57

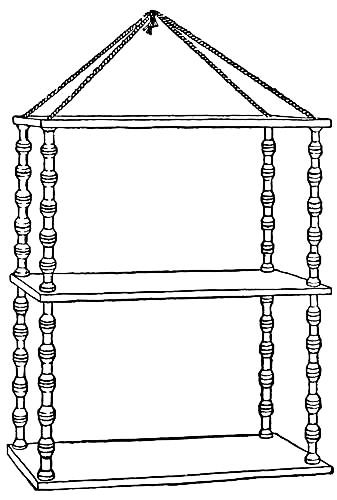

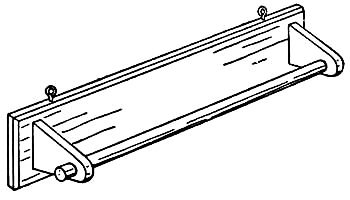

Simple and Inexpensive Furnishings—What the Room should Contain—A Cosey-corner—Pennants—Small Posters—Picture-frames—A Writing-desk—Another Style of Desk—An Ink-stand and Pen-tray—A Couch—A Window-seat—A Curio-cabinet—Book-shelves—A Blacking-case—A Towel-rack.

CHAPTER V

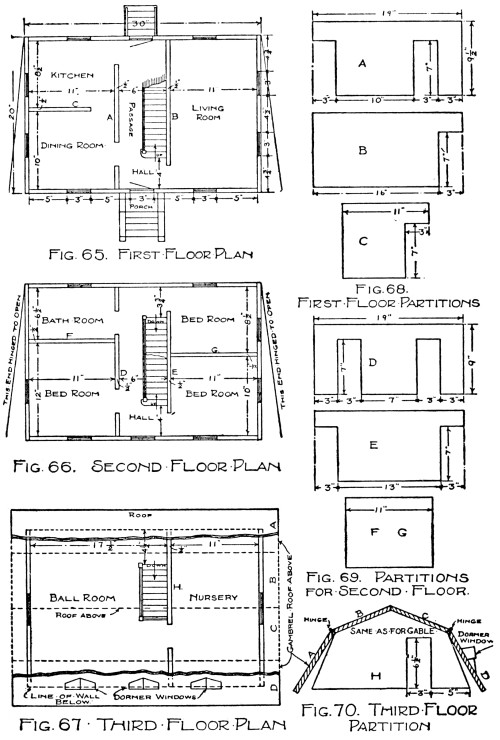

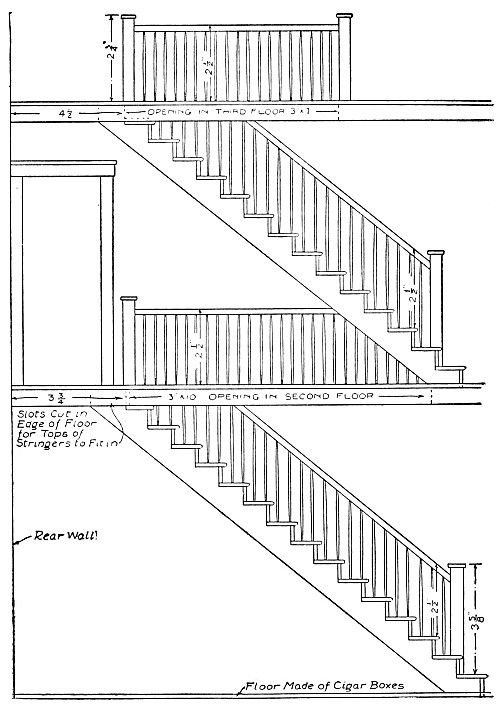

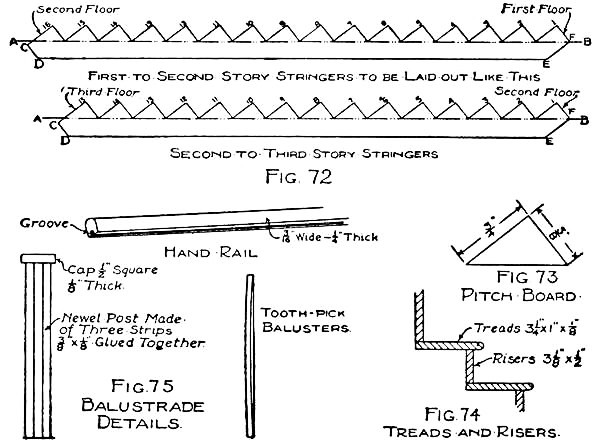

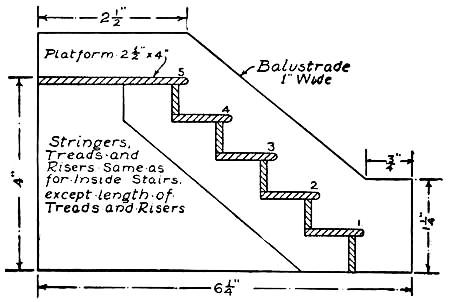

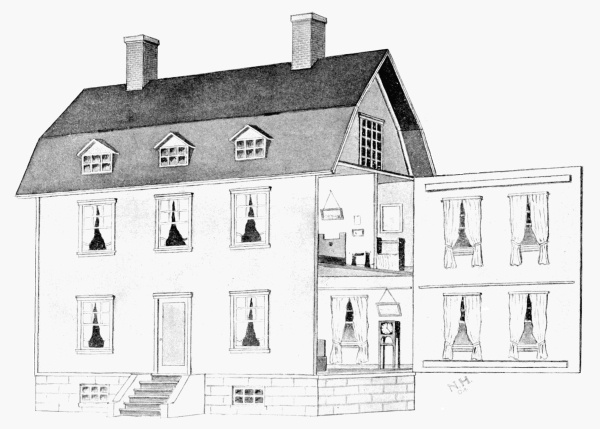

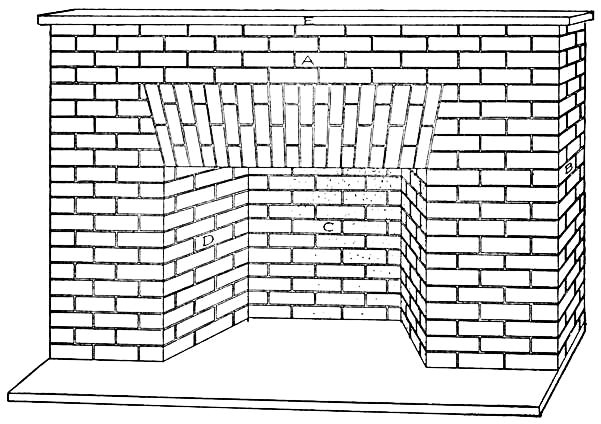

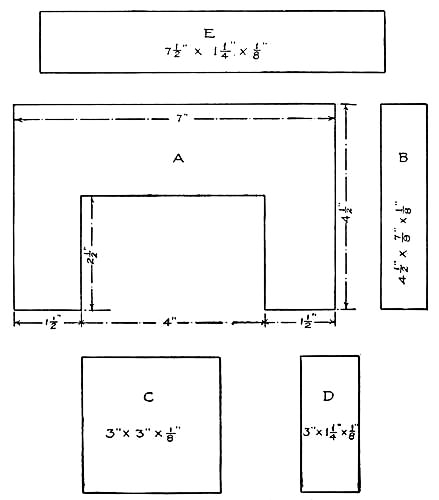

How to make a Doll-house71

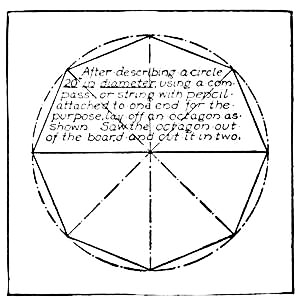

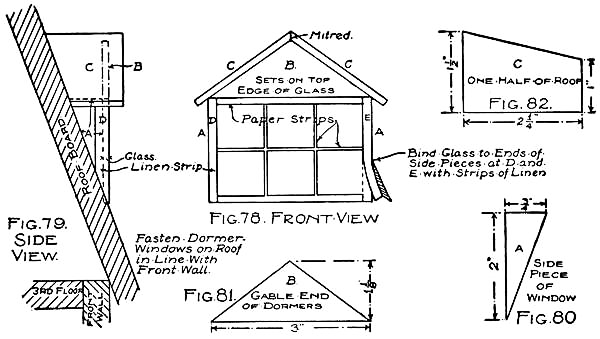

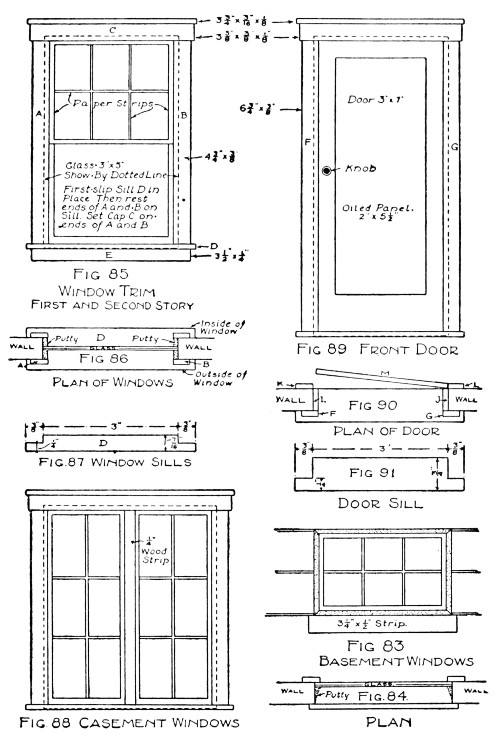

Store Doll-houses—Profit from making Doll-houses—The Materials Required—The Base—The Floors—Partitions and Walls—Stairways—Balustrades—Front and Rear Steps—The Gambrel Roof—The Gable-ends—The Doors and Windows—Outside Trimmings—Casters—The Chimneys—A Mantel and Fire-place—Andirons—The Interior Woodwork—Painting the House.

CHAPTER VI

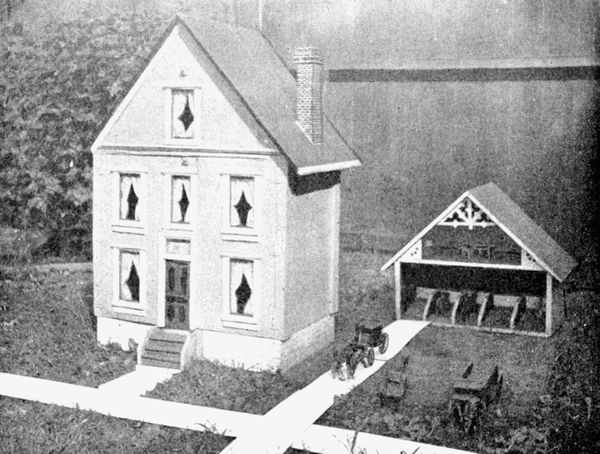

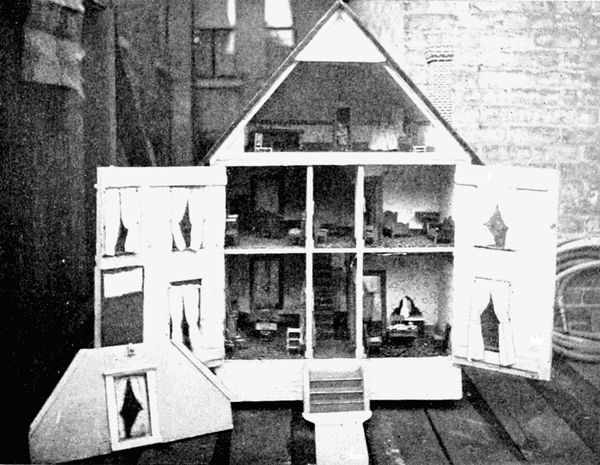

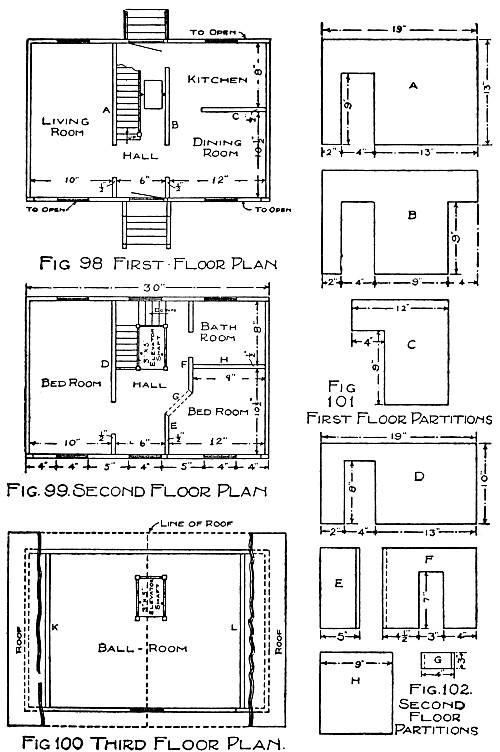

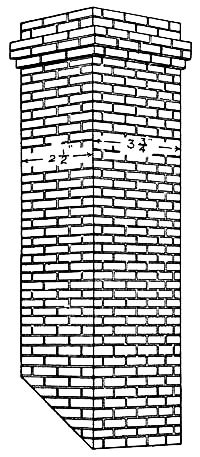

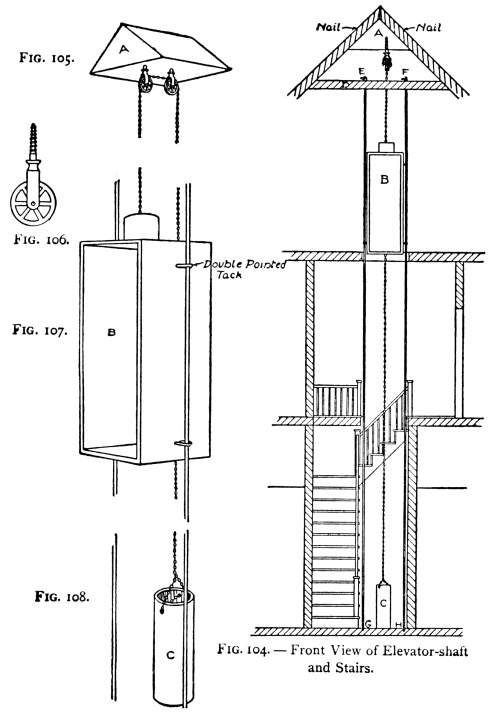

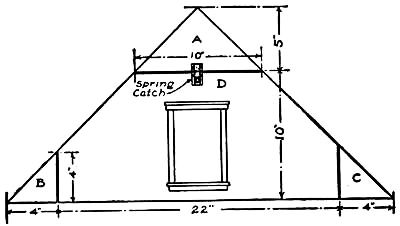

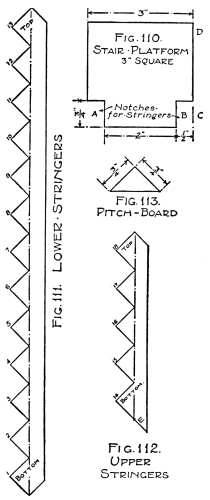

Another Doll-house and a Stable91

Packing-cases and Other Material—The Floor Plans—The Partitions and Walls—The Elevator-shaft—The Windows—The Roof—The Chimney—An Elevator—The Gable-ends—The Stairway—A Balustrade—Other Details.

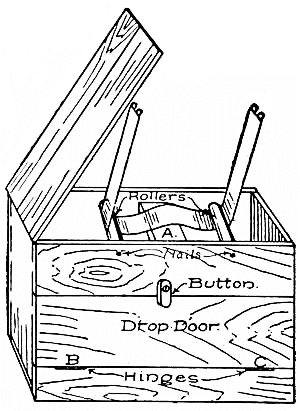

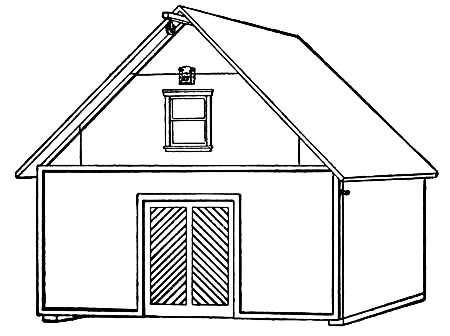

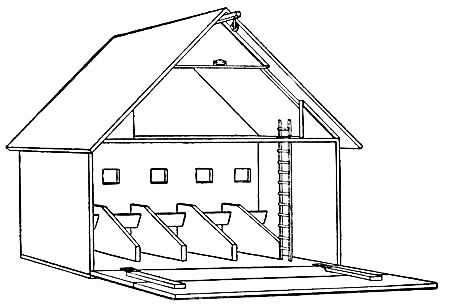

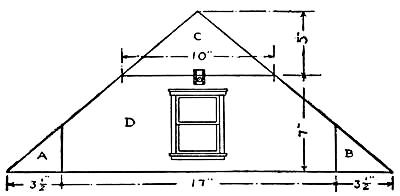

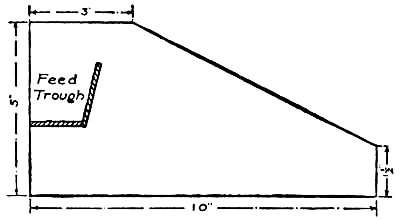

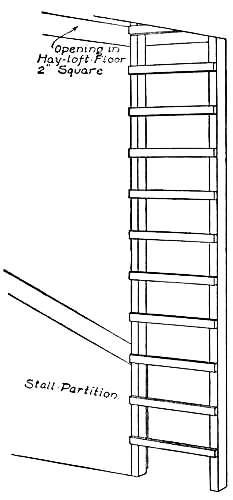

[Pg ix]How to make the Stable100

Dimensions of Stable—The First Story—The Roof—The Gable-ends—The Stall Partitions and Feed-troughs—Windows—Ladder to Hay-loft—Feed-hoist—The Drop-front—A Stable Door—Painting.

CHAPTER VII

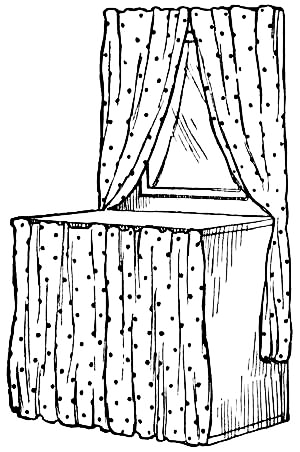

Furnishing the Doll-house105

The Walls and Ceiling—Hardwood Floors—Carpets and Rugs—Window-shades and Curtains—Portieres—Pictures—A Cosey-corner—Buying Furnishings.

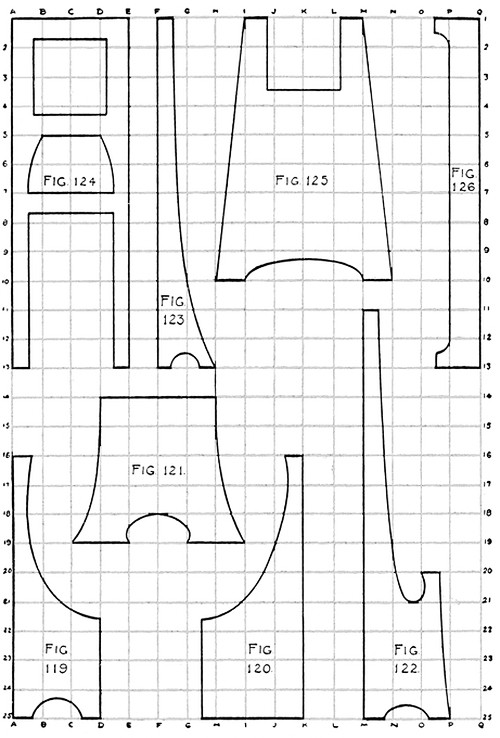

CHAPTER VIII

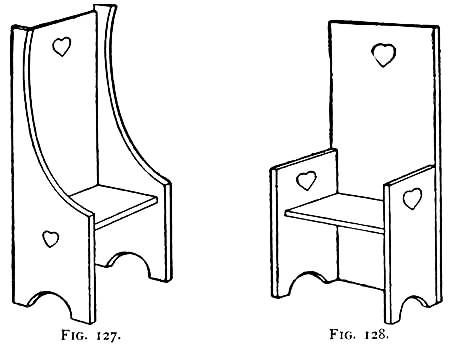

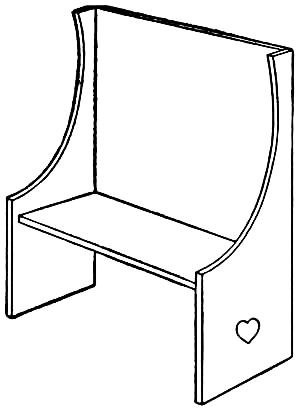

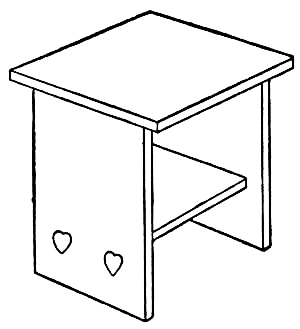

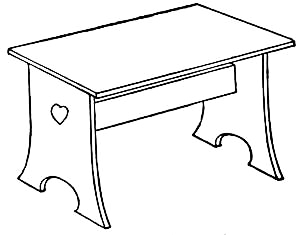

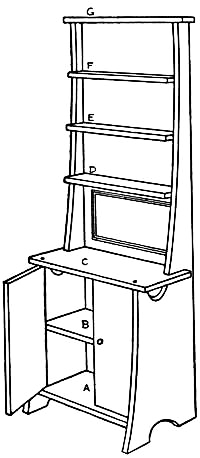

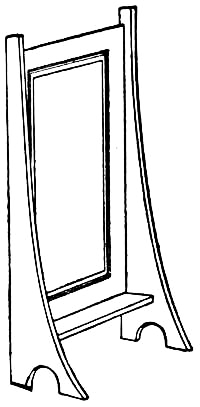

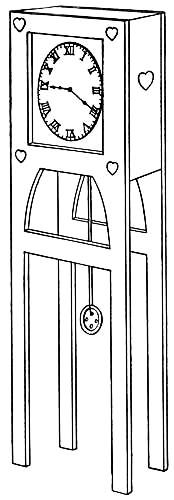

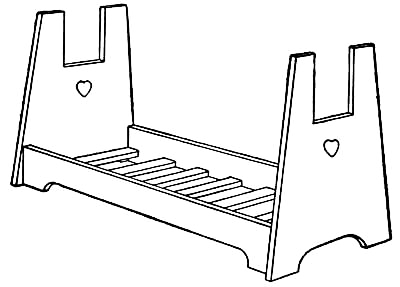

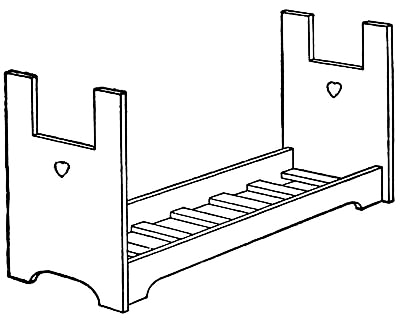

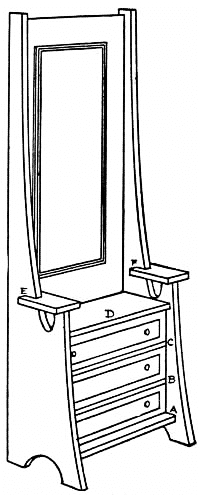

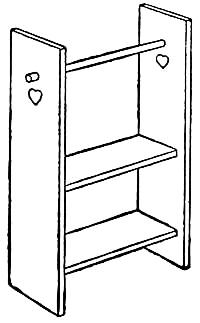

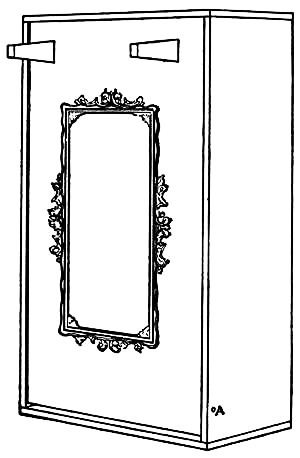

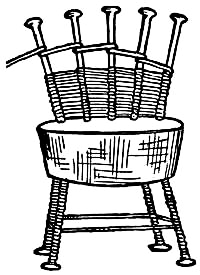

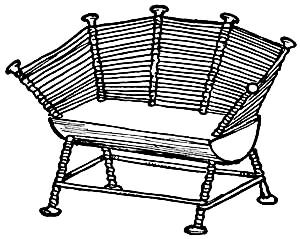

Doll-furniture109

Metal Furniture—Miniature Mission Furniture—Material—Drawing the Patterns—The Chairs—The Settee—Tables—A Side-board—A Mirror—The Grandfather's Clock—Kitchen Furniture—The Beds—The Dresser—A Wash-stand—Finishing.

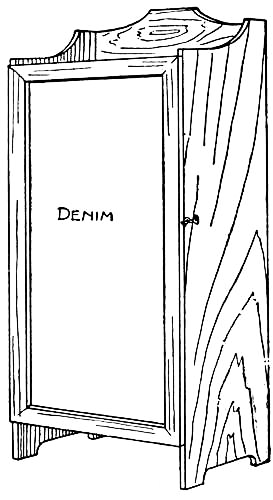

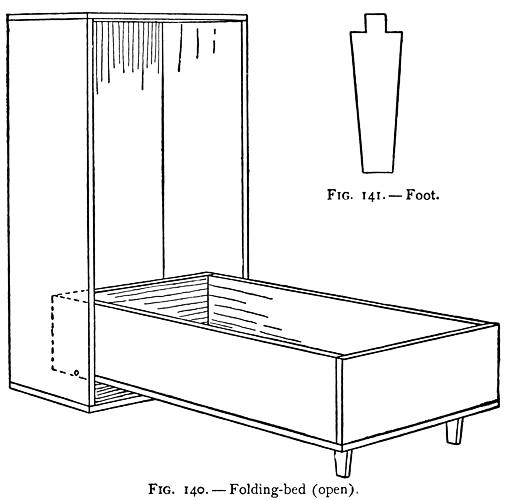

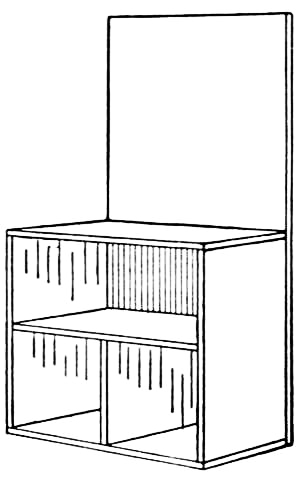

Other Cigar-box Furniture122

A Folding-bed—The Dresser—A Wardrobe.

CHAPTER IX

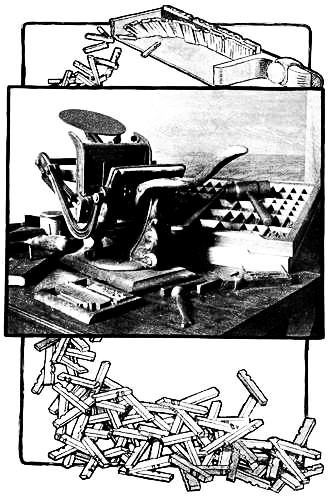

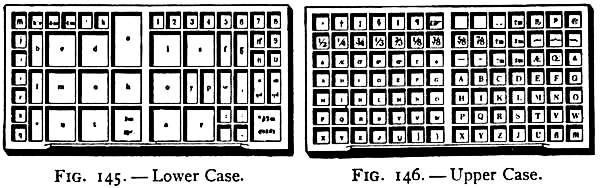

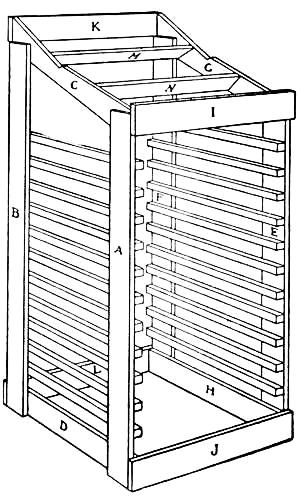

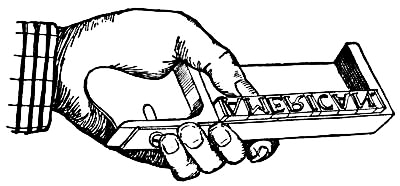

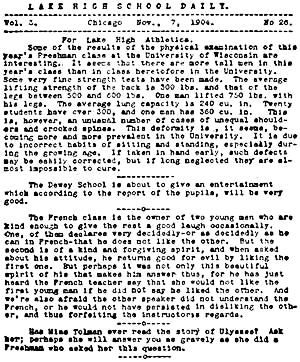

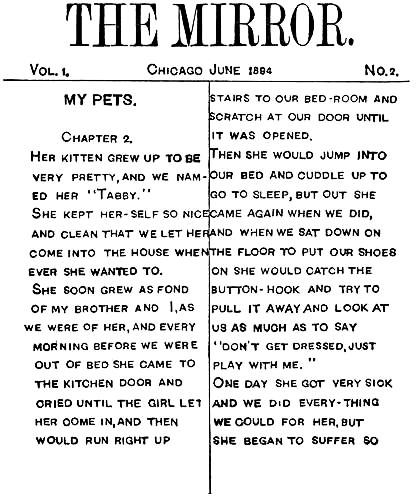

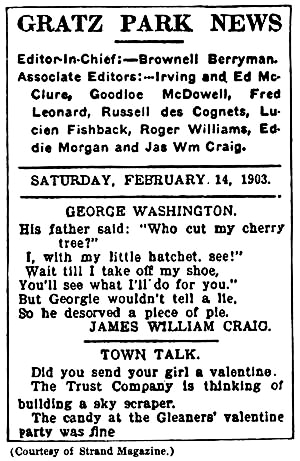

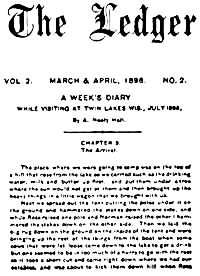

A Boy's Printing-shop126

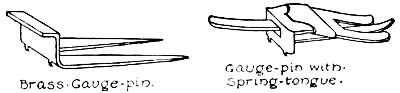

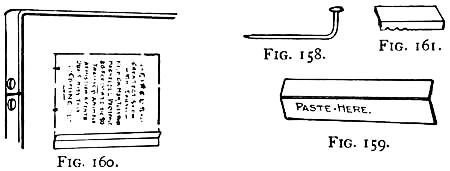

Location of Printing-shop—Equipment—Selection of Type—Type-cases—A Rack for Type-cases—A Composing-stick—A Composing-rule—Justifying—A Home-made Galley—"Pieing"—Proofs—The Imposing-stone—The Chase—Furniture—Locking-up a Form—Distribution—The Tympan—Overlaying—Underlaying—Gauge-pins—Inking the Press—Care of Rollers—Neatness—Receptacles for Materials—Care of Waste Paper and Oily Rags.

CHAPTER X

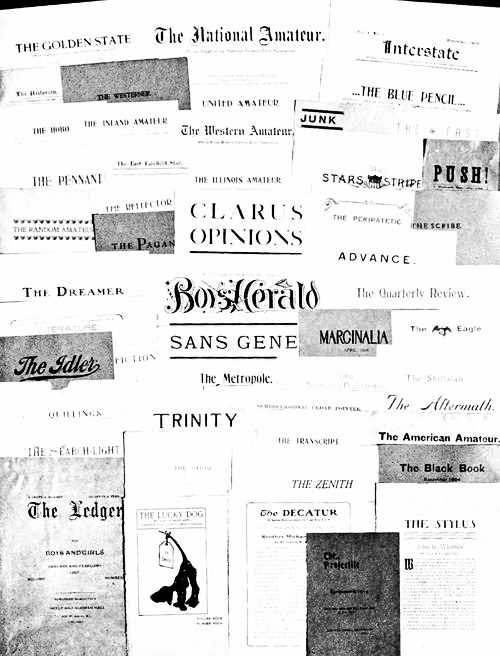

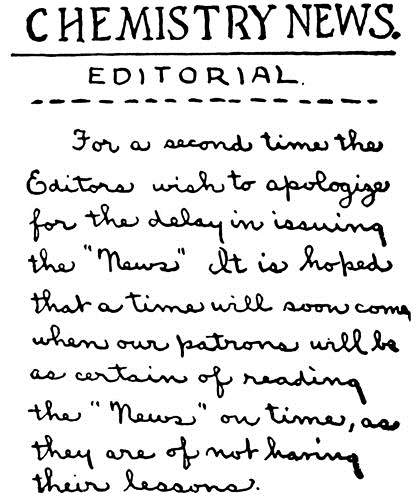

Amateur Journalism142

A Collection of Amateur Papers—Amateur Press Associations—Some Methods of Printing Papers—Examples of Amateur Papers—The Character of a Paper—Naming—The Frequency of Publication—The Size of Page—A Stereotyped Heading—The Choice of Type—A Cover—Binding—Advertisements—The Advertisers' Dummy—Second-class Matter.

[Pg x]CHAPTER XI

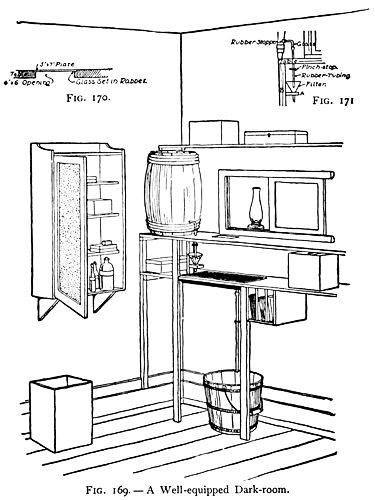

A Boy's Dark-room153

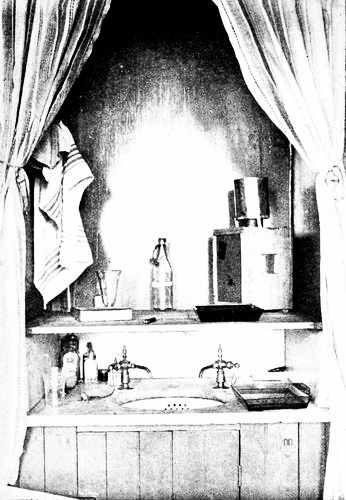

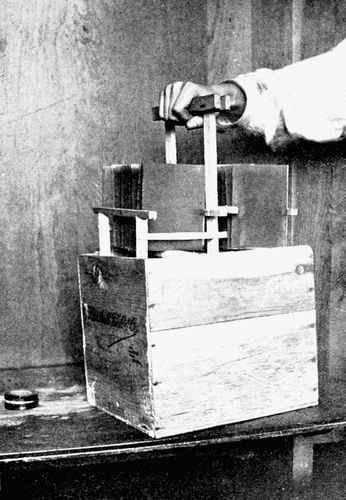

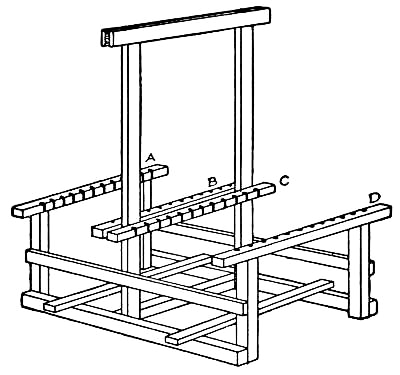

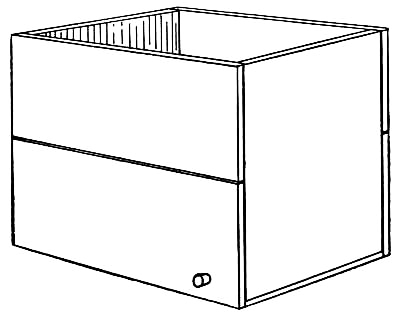

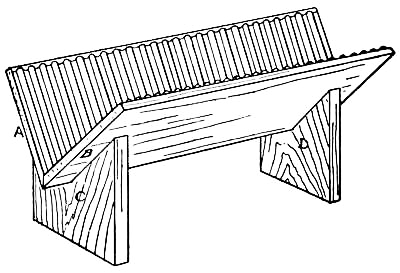

Profit in Photography—The Necessary Equipment—The Bedroom as a Dark-room—The Bath-room as a Dark-room—Another Scheme for a Dark-room—A Work-table—Running Water—A Water-tank—A Sink—A Washing-box—A Drying-rack—Another Scheme for a Drying-rack—A Cabinet—A Ruby-light—A Home-made Lantern—A Plate-lifter—Classifying and Preserving Negatives—Manila Envelopes—A Negative-case.

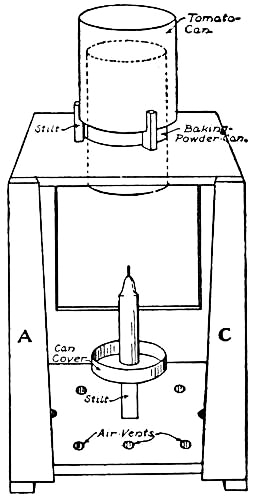

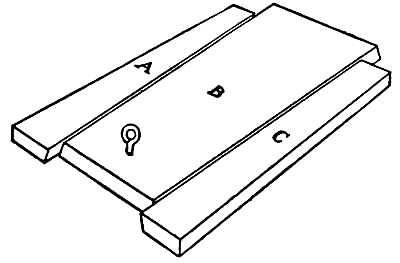

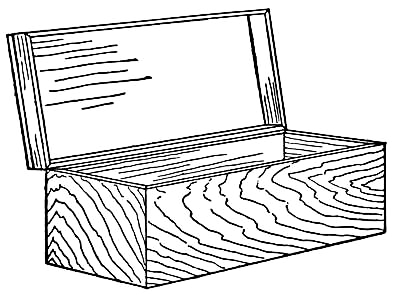

CHAPTER XII

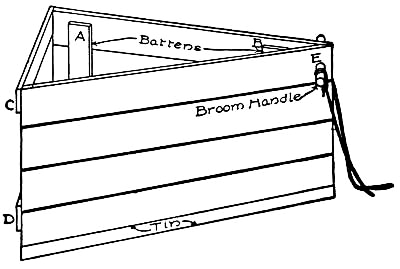

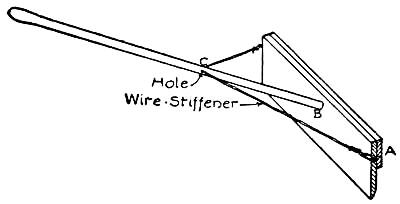

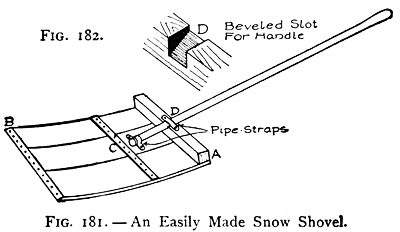

A Winter Enterprise169

An Opportunity for Making Money—A Snow Plough—A Scraper—A Snow Shovel.

PART II

OUTDOOR PASTIMES

CHAPTER XIII

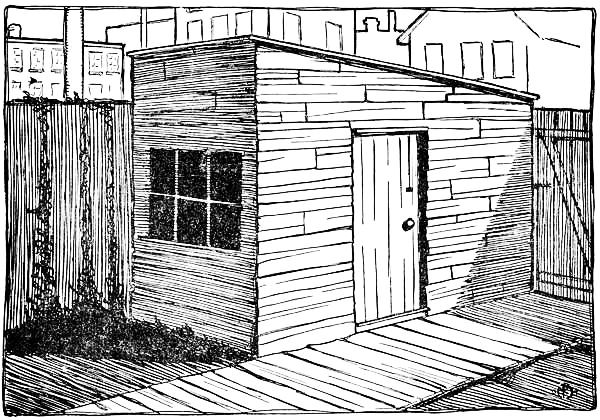

A Back-yard Club-house175

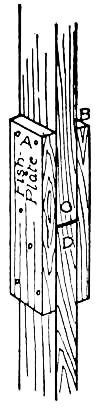

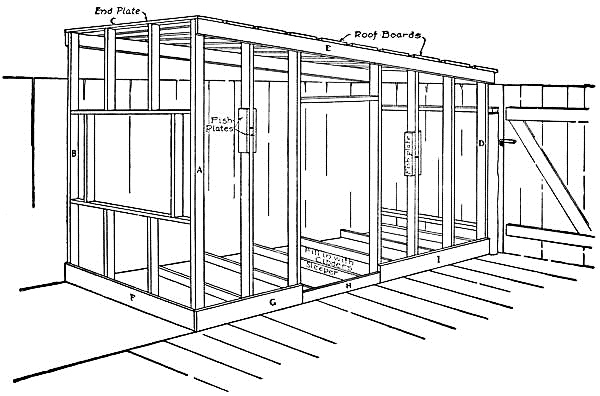

How Some Boys Built a Club-house—A Mysterious Letter—Drawing the Plan of a Club-house—The Material—Fishing Studs—Staking out the Building—The Studs—Boarding up the Sides—The Roof—The Floor—A Window-sash—A Batten Door—Wooden Latch—Calking up Cracks.

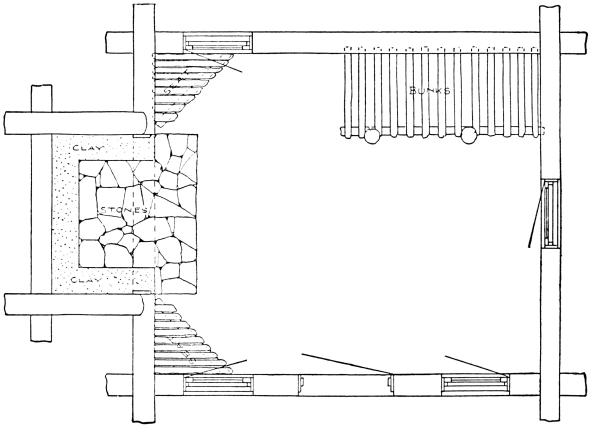

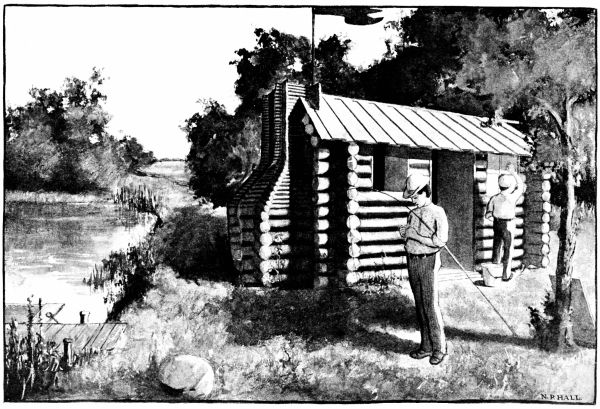

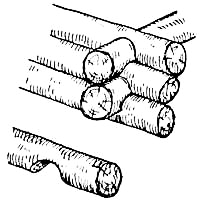

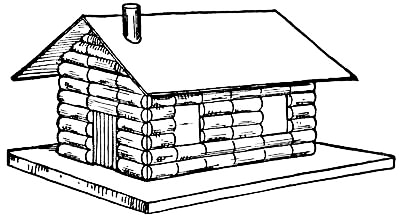

CHAPTER XIV

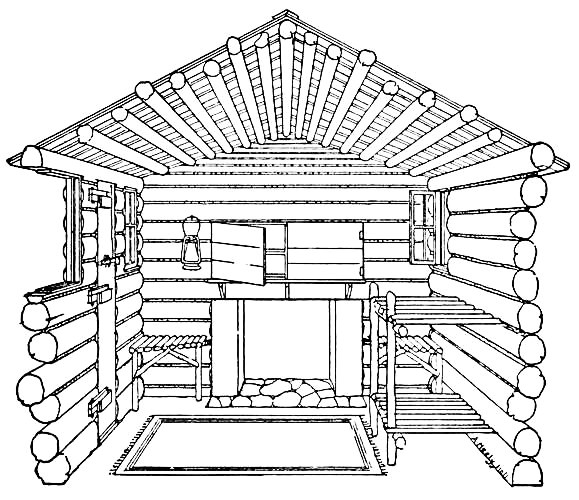

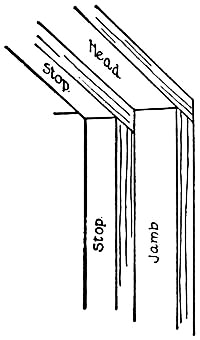

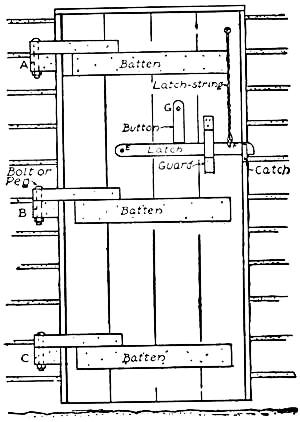

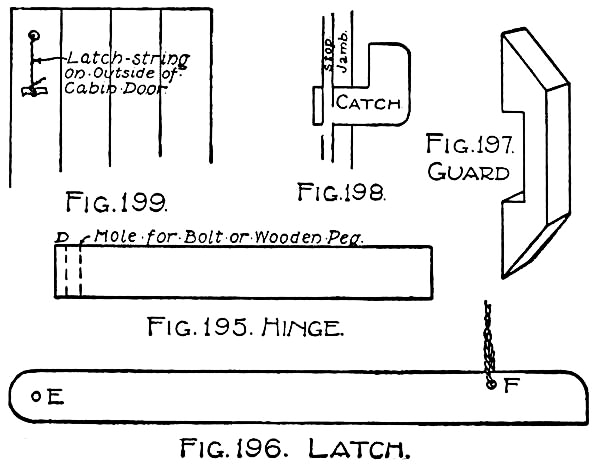

How to build a Log-cabin186

The Pioneer Cabin—The Cabin of To-day—Selection of a Site—Design and Size—The Material—Staking out the Cabin—The Lock-joint—The Sills—Construction of Roof—Ridge Boards—A Log Chimney and Fire-place—Calking—A Mud Floor—The Windows—The Cabin Door—Wooden Hinges—Wooden Latch—The Latch-string—A Mantel-shelf—Provision Cupboard—Rustic Seats—Bunks—A Camp-table—A Few Pointers about Camping—Utensils—Other Necessities—Provisions.

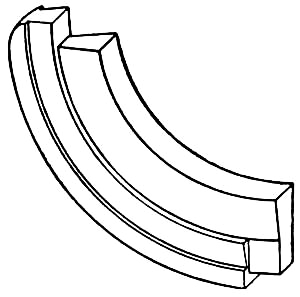

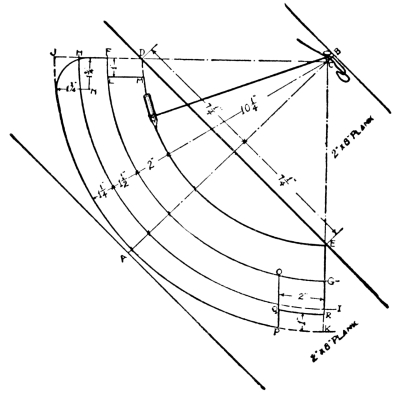

[Pg xi]CHAPTER XV

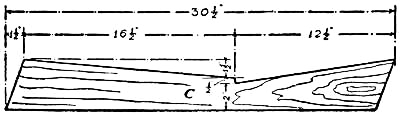

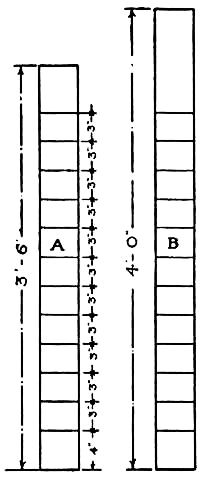

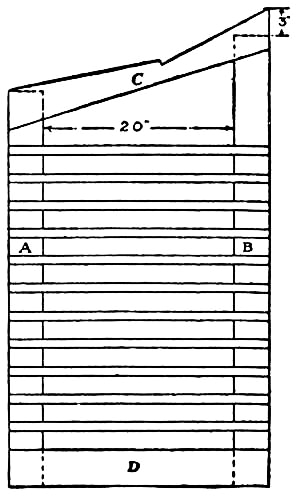

How to build a Canvas Canoe201

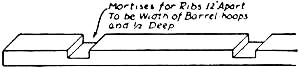

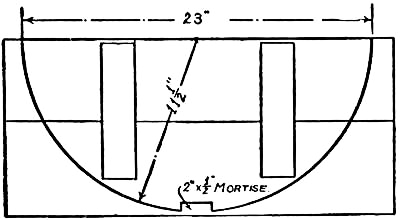

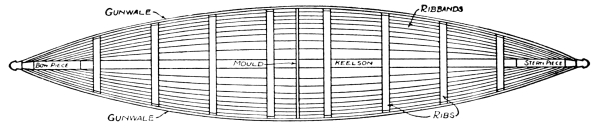

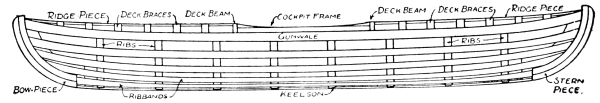

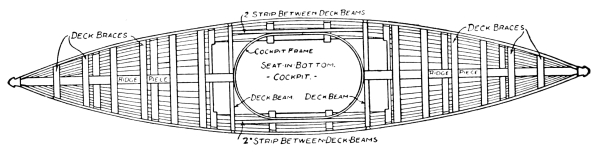

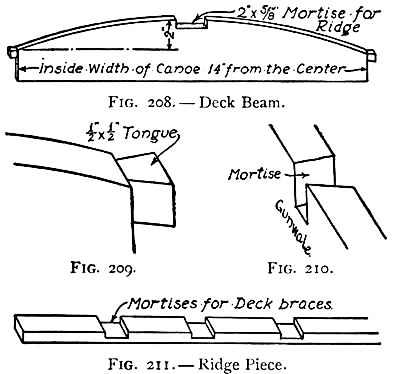

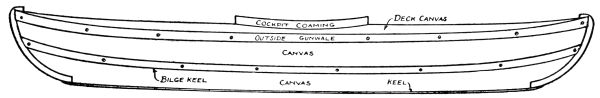

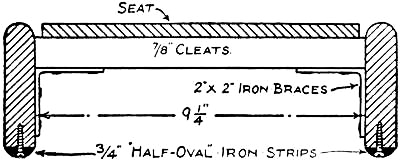

Canoeing as a Sport—Popularity of Canvas Canoes—Materials—The Bow and Stern Pieces—The Keelson—The Mould—Putting the Framework Together—The Gunwales—The Ribbands—The Deck Beams—The Ridge Pieces—The Deck Braces—The Cockpit—The Canvas Covering—The Deck—Painting—The Cockpit Coaming—The Keel—The Bilge-keels—Outside Gunwales—A Seat—How to mend Punctures—A Single Paddle.

CHAPTER XVI

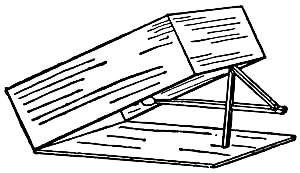

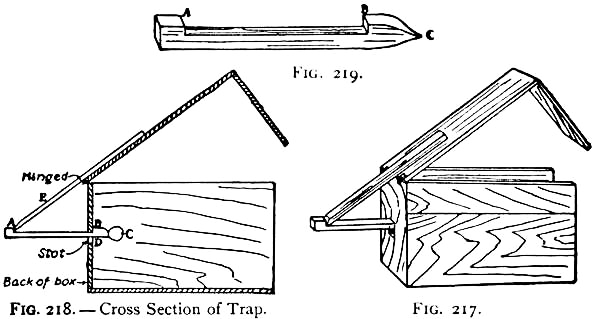

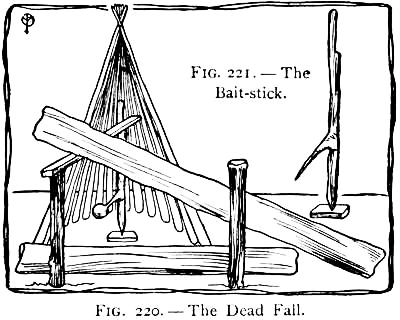

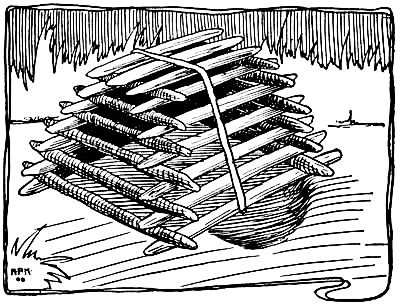

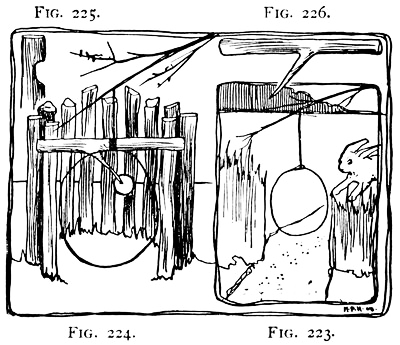

Home-made Traps218

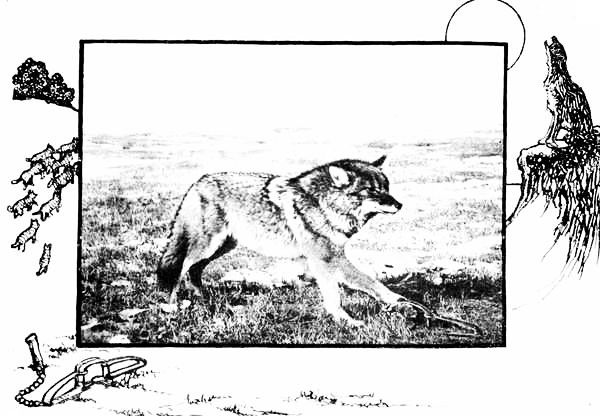

Trapping as a Pastime—The City Boy and his Country Cousin—The Figure-four Trap—A Box Trap—The Dead Fall—The Sieve Trap—The Coop Trap—A Rabbit Snare—A Twitch-up—The Professional Trapper—Wolves and Coyotes—Story of a Trapped Indian.

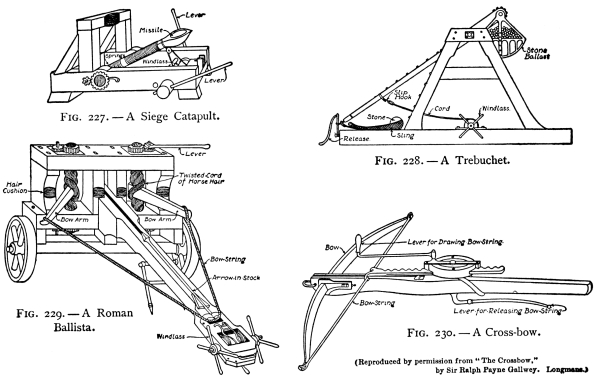

CHAPTER XVII

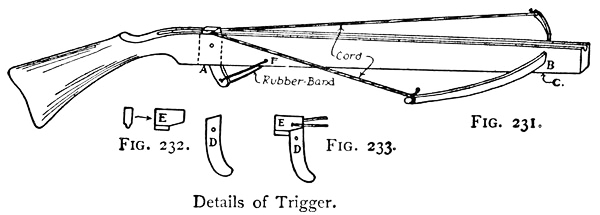

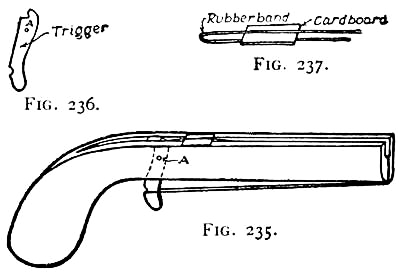

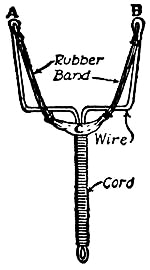

Toy Guns, Targets, and Bows and Arrows229

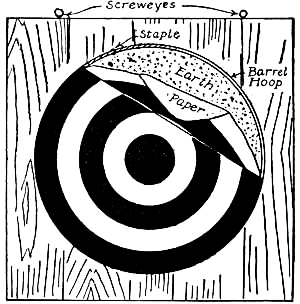

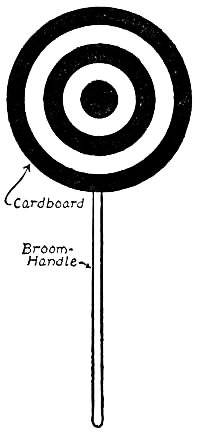

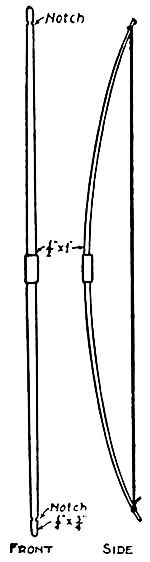

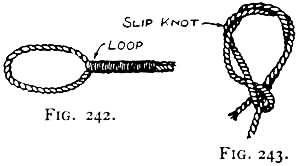

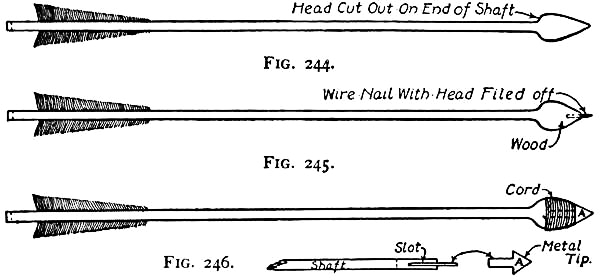

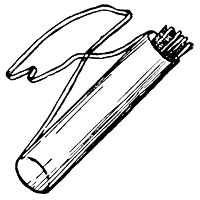

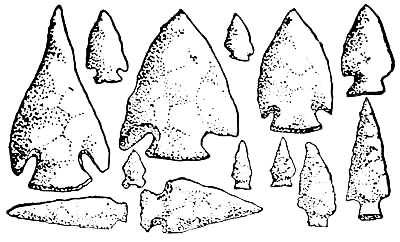

Ancient War Engines—New Idea for a Cross-bow—Shingle Arrows—A Toy Pistol—Cardboard Bullets—A Shot-gun—An Elastic Sling—A Boy's Barrel-hoop Target—A Simpler Target—How Points are Scored—The Bow and Arrow—Length of Bow—The Bow-string—The Arrow-shafts—Preparing Arrow-heads—Feathering—A Quiver—Proper Position for Shooting with Bow—The Indian's Bow—How his Arrows were made and Feathered—The Preparation of his Arrow-heads.

CHAPTER XVIII

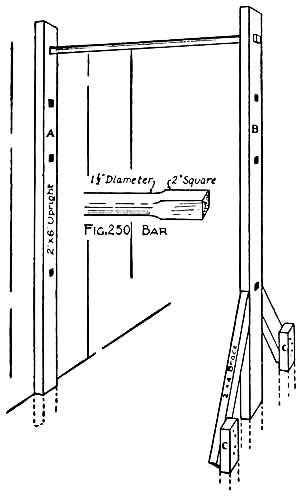

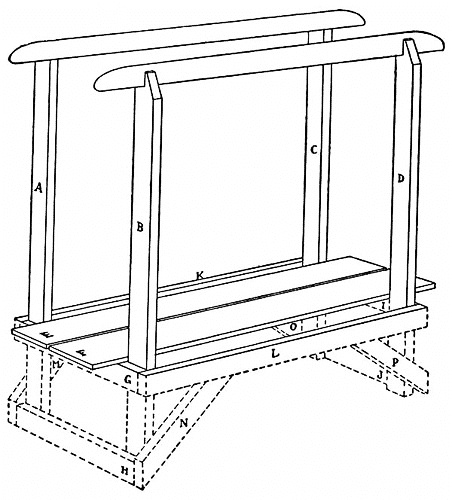

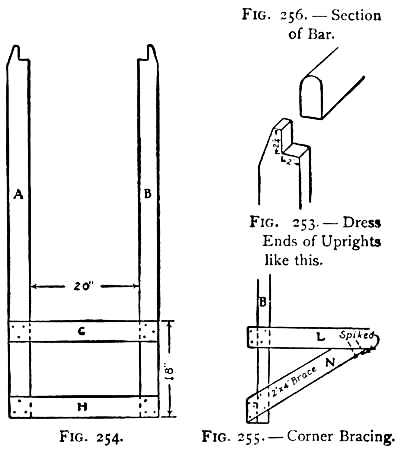

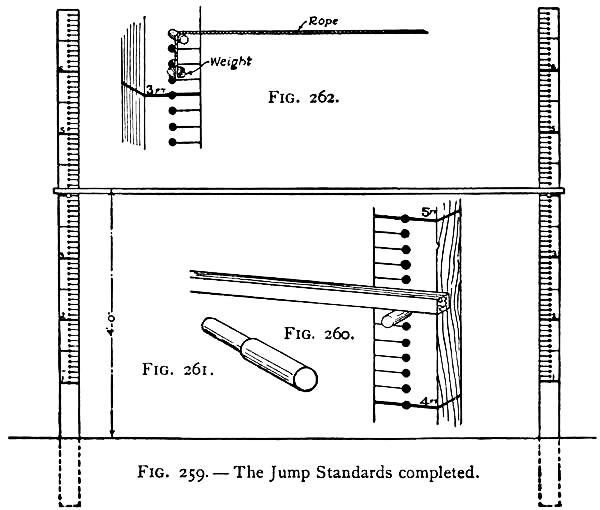

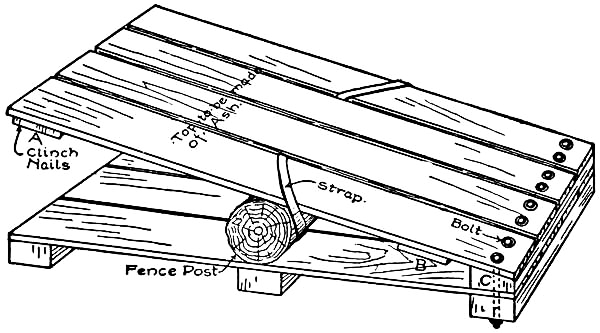

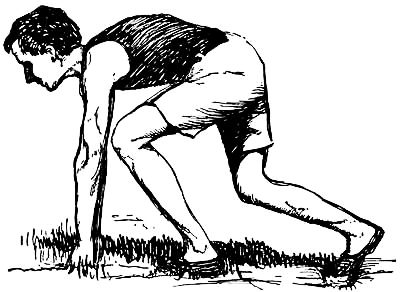

An Outdoor Gymnasium243

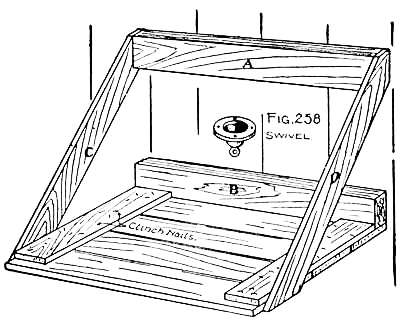

Location for Gymnasium—A Horizontal Bar—Tumbling Mat—Parallel Bars—The Punching-bag Platform—A Pair of Jump Standards—A Vaulting Pole—A Spring-board—Hurdles—A Running Track—Method of Starting for Short Sprints—Mark for Broad Jumping—An Athletic Club—Athletic Meets.

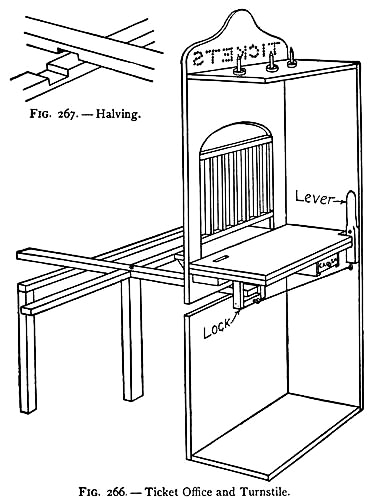

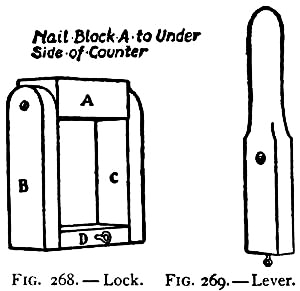

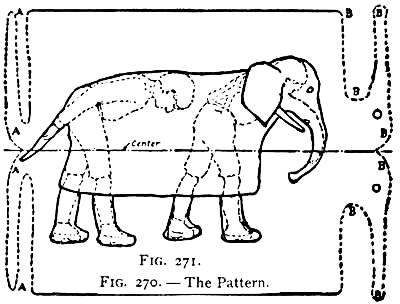

[Pg xii]CHAPTER XIX

A Back-yard Circus255

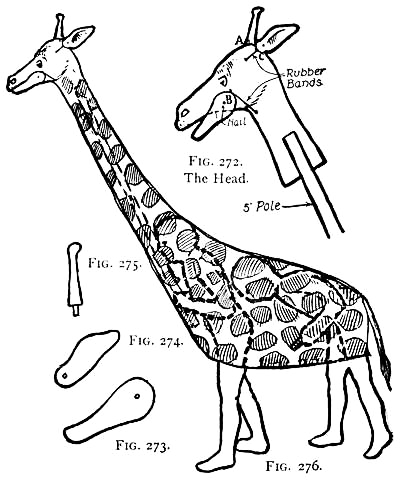

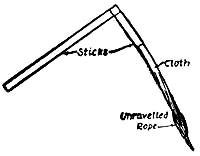

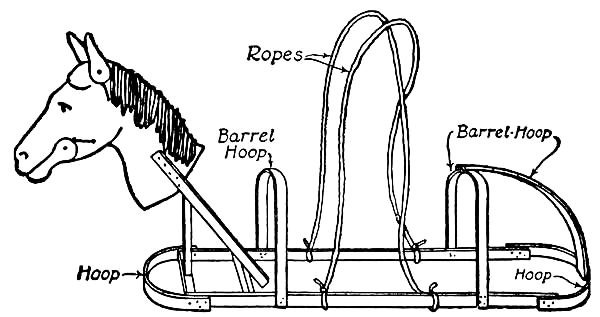

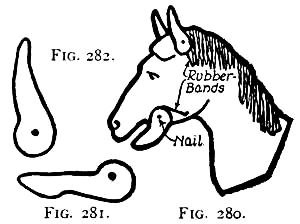

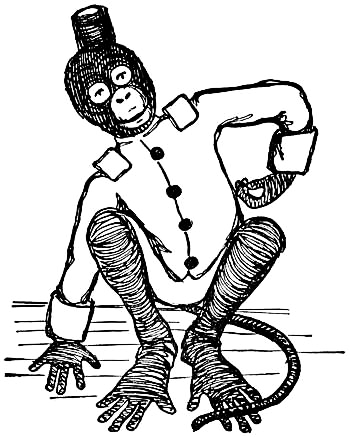

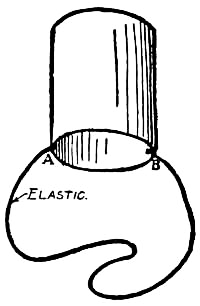

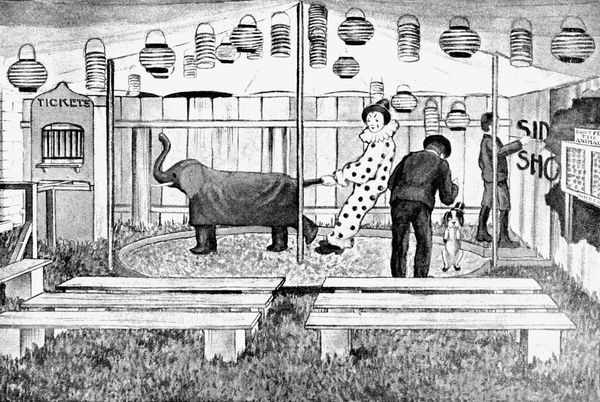

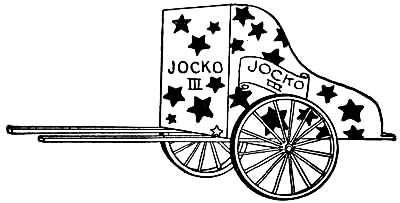

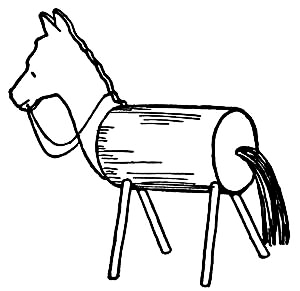

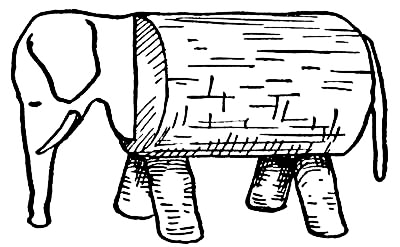

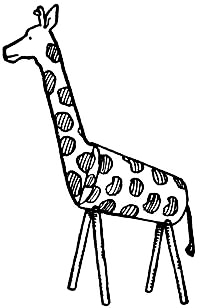

The Ancient Roman Circus—The Circus of To-day—How Several Boys gave a Circus—Preparing the Yard for a Circus—Making the Ring—Good Circus Seats—A Tent—Decorating the Tent—A Ticket Office—A Turnstile—The Side Show—Cages for Side Show—Animated Animals—The Elephant—The Giraffe—The Two-legged Wild Horse—The Wild Man of Borneo—A Monkey's Make-up—The Ring Master—The Clown's Suit—The Attendants—Ideas for a Performance—A Slapper—Looping the Hoop on a Giraffe—A Chariot—Parades—The Advertising Signs.

CHAPTER XX

Suggestions for Fourth of July272

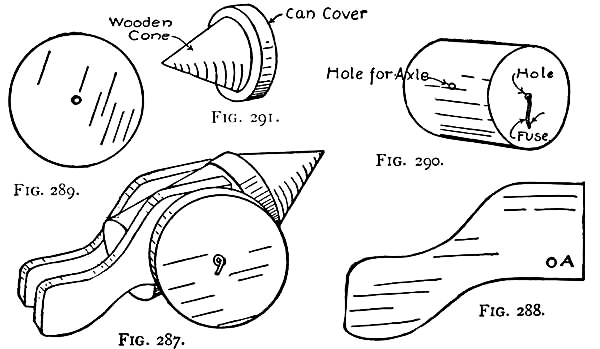

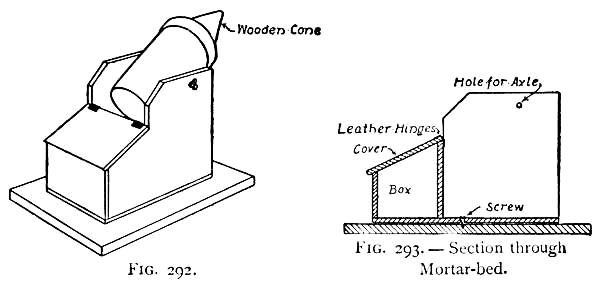

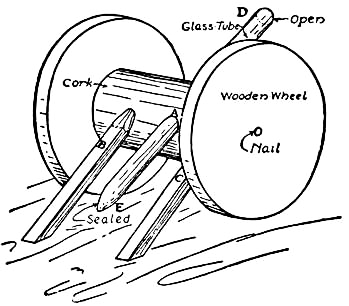

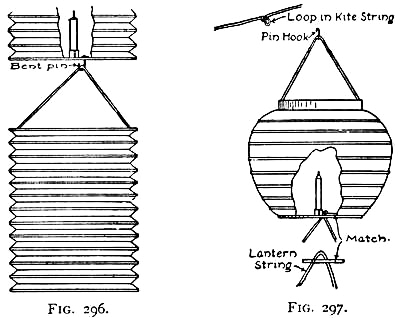

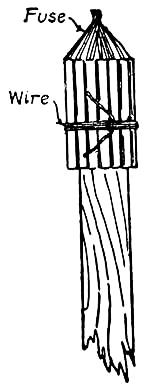

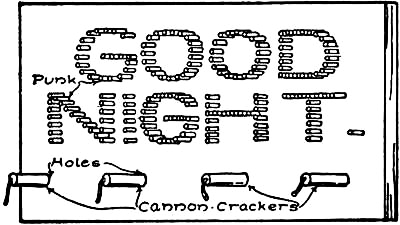

The First Fourth of July Celebration—Pyrotechnics Costly and Dangerous to Make—The Making of Harmless and Inexpensive Fireworks—A Fire-cracker Cannon—To fire the Cannon—A Fire-cracker Mortar—Mimic Battles with Paper Soldiers—Another Toy Cannon—To fire the Cannon—Firing Fireworks from Kites—Firing a Pack of Fire-crackers from a Kite—Shooting Nigger-chasers—Japanese Lanterns hung from Kite-strings—A Shooting-torch—A Final Set-piece.

CHAPTER XXI

Halloween281

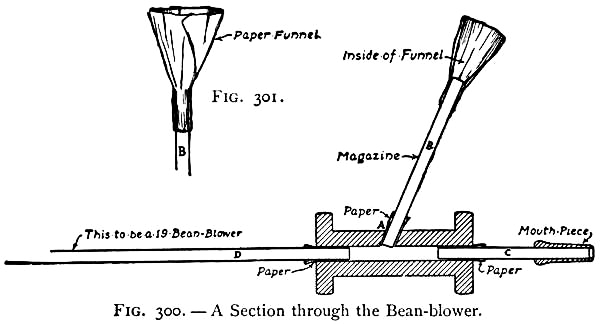

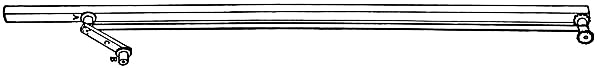

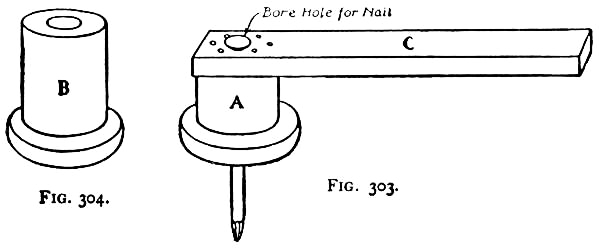

Ancient Superstitions and Origin of Halloween—A Magazine Bean-blower—A New Style of Tick-tack—A Clockwork Tick-tack—The Goblin-man—The Disappearing Rope.

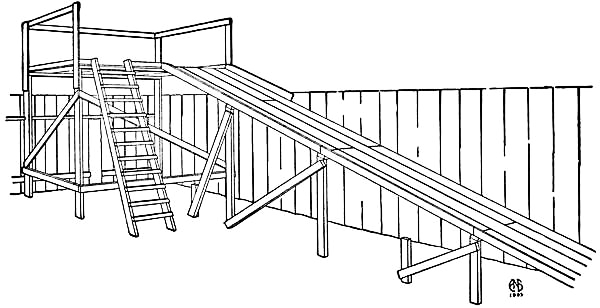

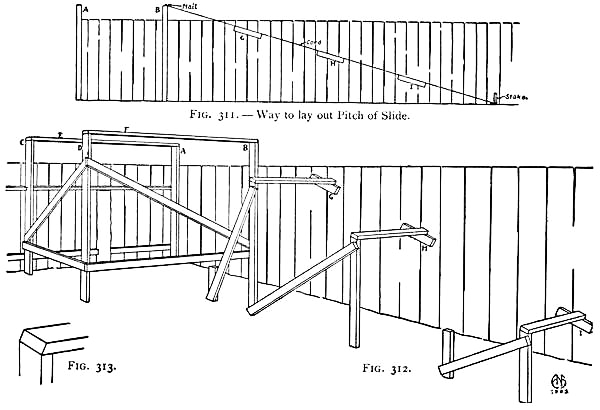

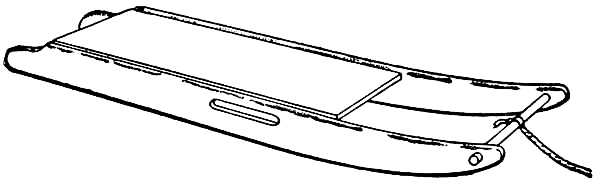

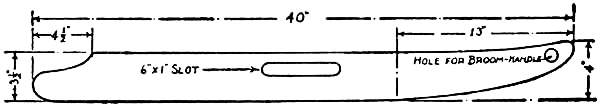

CHAPTER XXII

A Back-yard Toboggan-slide291

One Advantage of a Small Slide—Location—Length—The Platform—Framework—Railing around Platform—A Ladder—Making a Swift Slide—A Home-made Sled—The Runners—ReŽnforcing the Runners.

[Pg xiii]PART III

INDOOR PASTIMES

CHAPTER XXIII

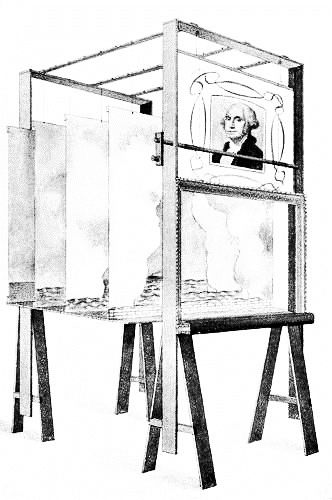

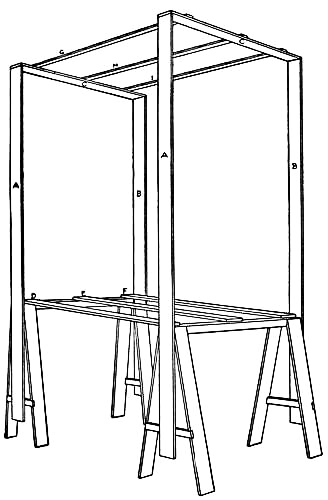

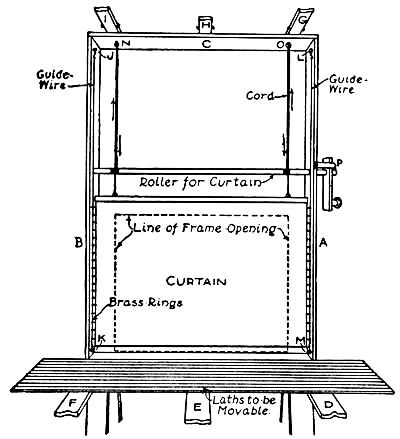

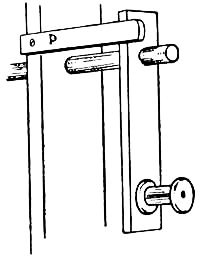

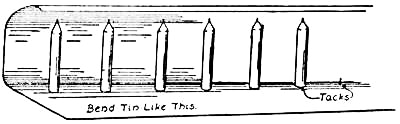

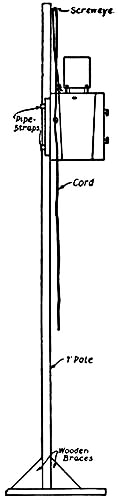

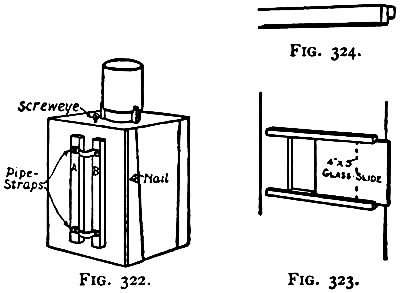

A Miniature Theatre303

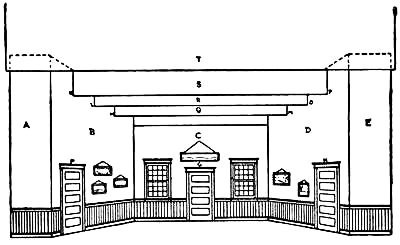

An Interesting Entertainment—A Picture-frame Proscenium—The Stage Framework—The Gridiron—The Stage Floor—The Drop-curtain—Lighting the Theatre—The Footlights—Floodlights—Colored Lights—Spotlights—Admission Tickets and Programmes.

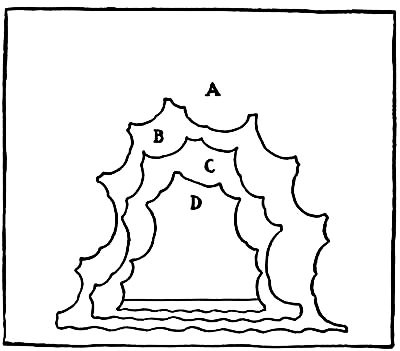

CHAPTER XXIV

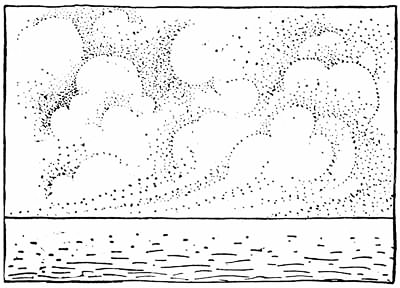

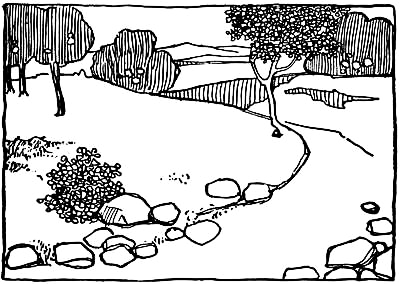

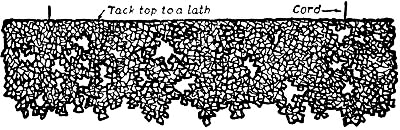

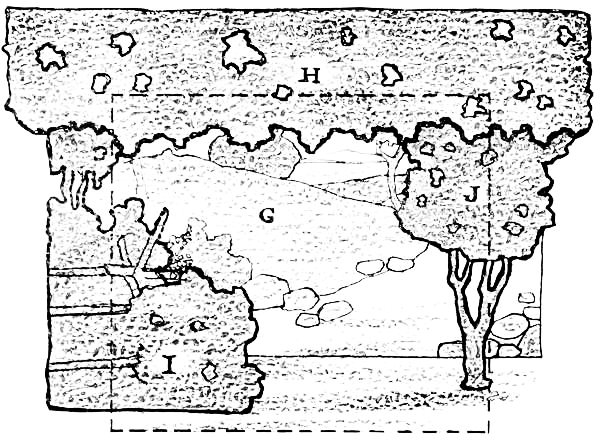

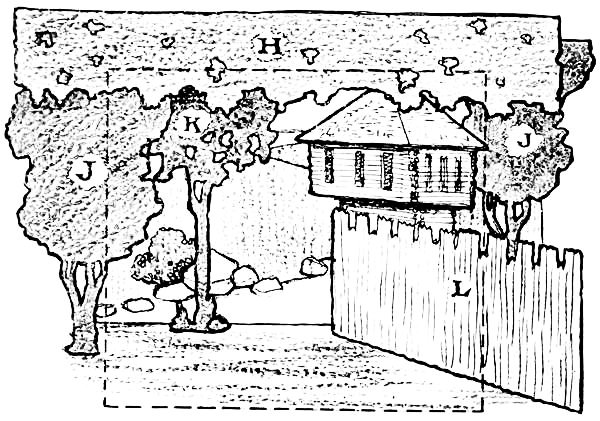

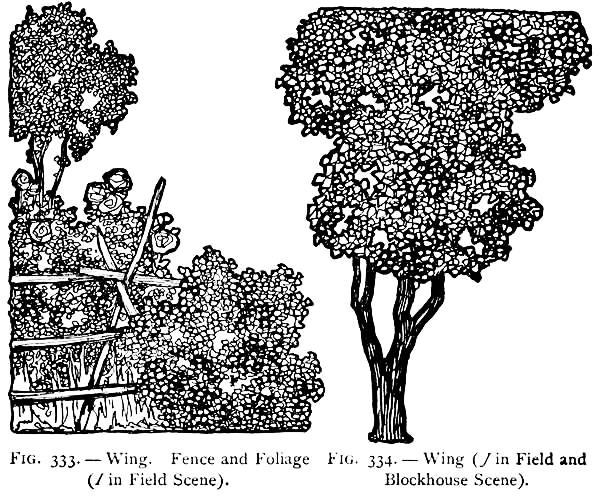

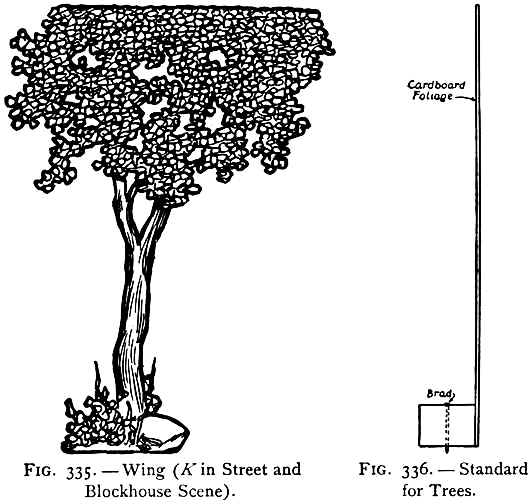

Scenery, Properties, and Mechanical Effects311

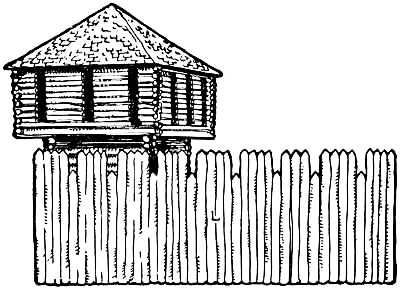

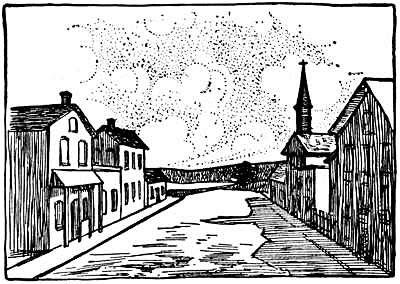

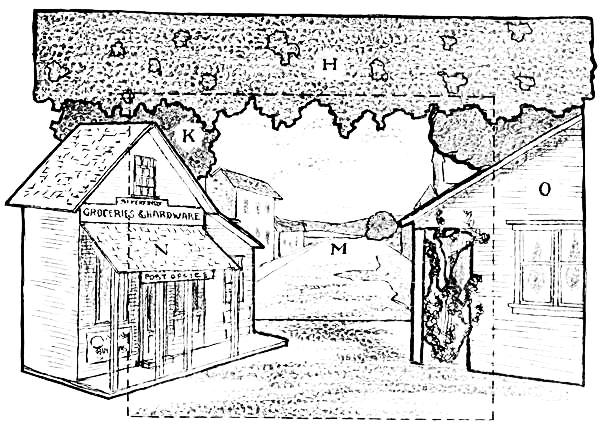

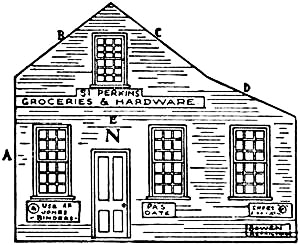

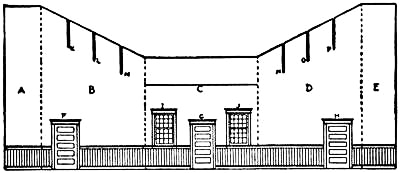

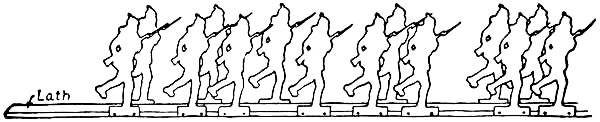

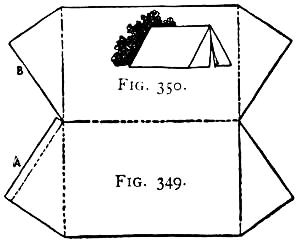

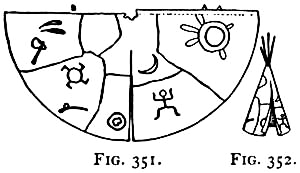

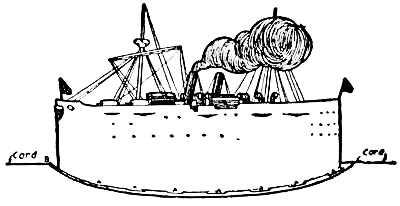

Materials for Scenery—An Ocean Scene—Additional Waves—Frames for Drops—A Mid-ocean Scene—A Seashore Scene—A Field Scene—The Trees—A Blockhouse Scene—Pine Boughs for Trees and Shrubbery—Moss for Mounds and Hills—Rustic Bridges—A Pond or Lake—A Street Scene—An Interior—A War Drama—Paper Soldiers—Scheme for Marching Soldiers—Separate Standards—A Jointed Figure—Stage Properties—Tents—An Indian Teepee—Battleships—Trains and Wagons—Mechanical Effects—Thunder—Rain—Wind—Lightning—The Roar of Cannon.

CHAPTER XXV

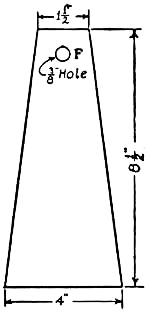

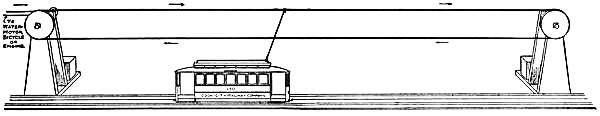

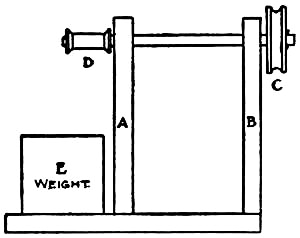

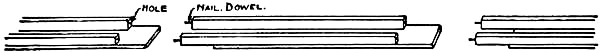

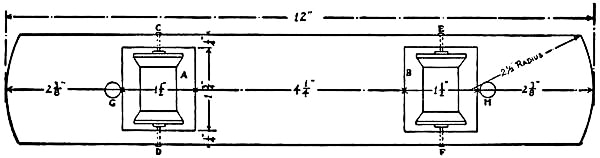

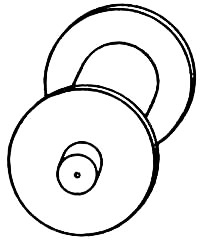

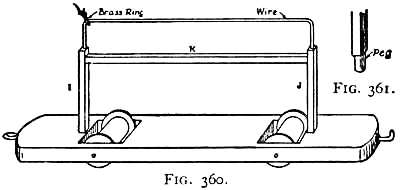

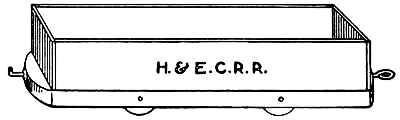

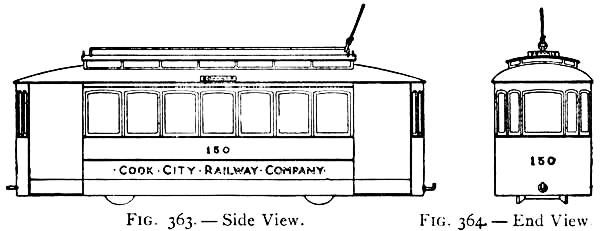

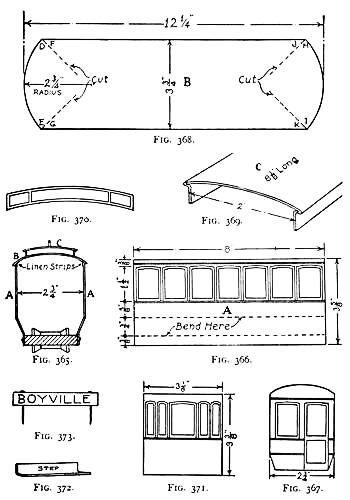

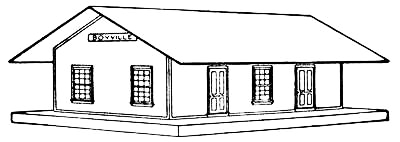

Making a Toy Railway331

The Trolley-line—Supports for Trolley-line—Power for Operating Railway—Tracks—The Cars—A Gondola Car—A Street Car—Other Cars—Operation of Railway—A Station.

CHAPTER XXVI

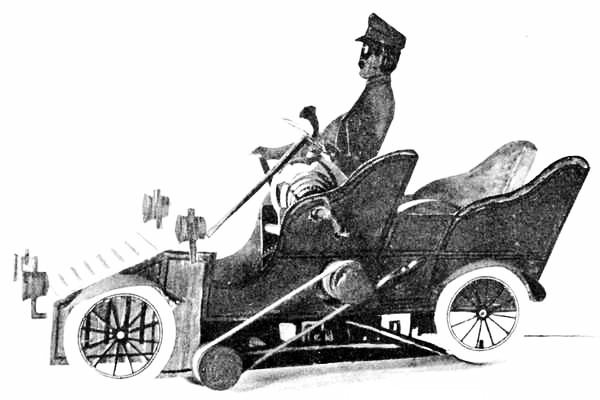

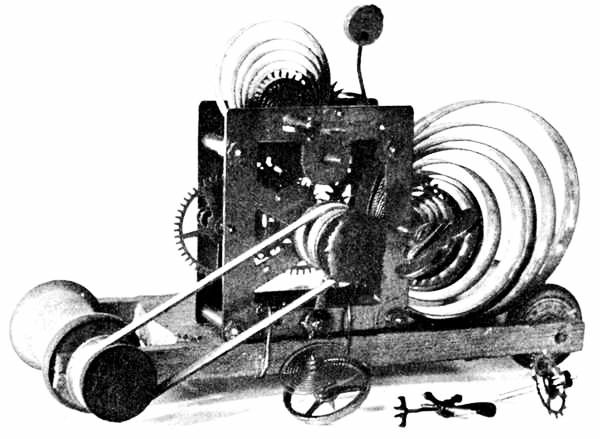

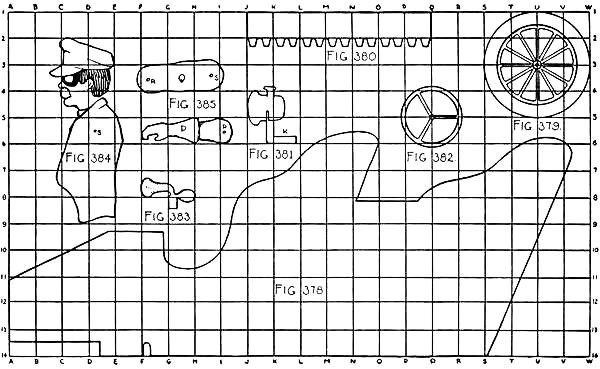

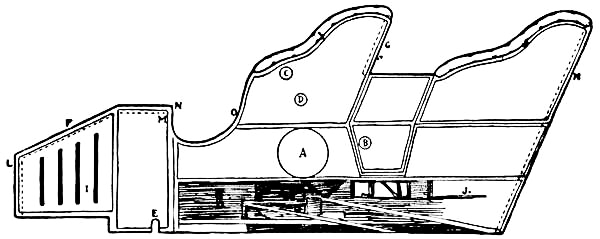

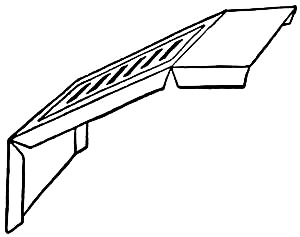

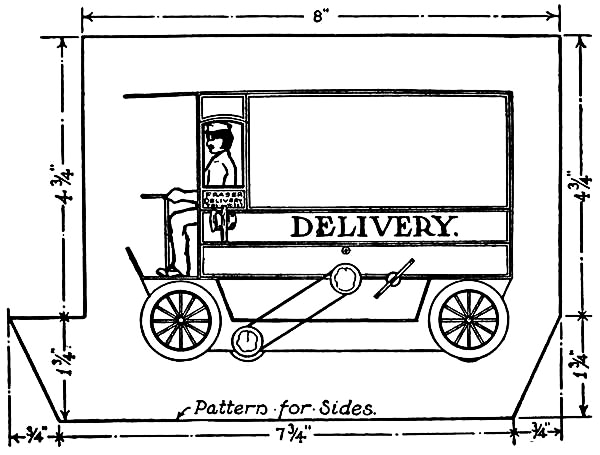

Clockwork Automobiles343

Procuring a Set of Clockworks—An Automobile Touring-car—The Frame—Preparation of Clockworks—The Belt—Testing the Machine—The Cardboard Sides—Wheels—Mud-guards—Lamps—The Steering-wheel—A Horn—The Brake—The Chauffeur—Painting [Pg xiv] the Machine—An Automobile Delivery Wagon—The Cardboard Sides—The Wheels—Other Portions—Painting the Wagon—A Clockwork Railway.

CHAPTER XXVII

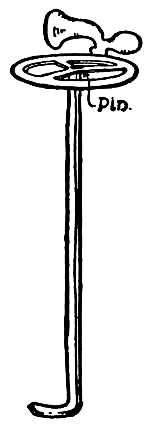

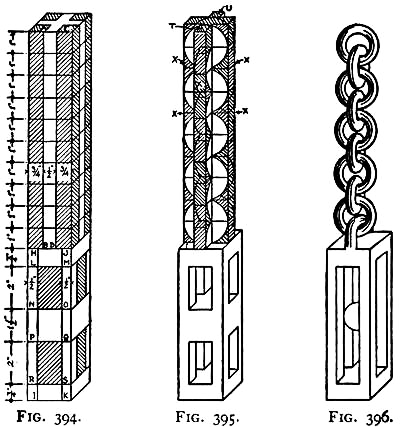

Work to do with a Knife356

How Boots were Marked in a Penitentiary—A Home-made Fountain Pen—The Magic Pin-wheel—To Operate the Pin-wheel—A Wooden Chain and Rattle—The Chain—The Rattle—Finishing the Chain and Rattle.

CHAPTER XXVIII

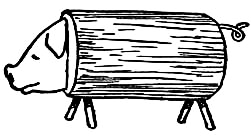

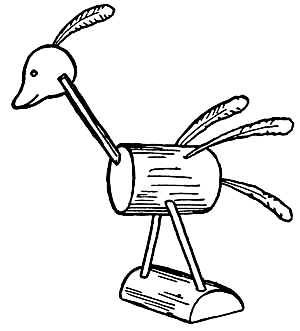

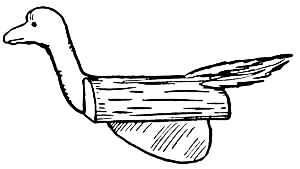

Cork Toys363

Materials Required—Cork Animals—A Pig—A Horse—The Elephant—The Giraffe—A Porcupine—Other Animals—The Korka-bird—A Duck—Canoes—Small Sail-boats—Cork Furniture—A Chair—The Sofa—A Small Tabouret—A Toy Log-cabin.

CHAPTER XXIX

(In addition to more than four hundred text illustrations.)

| A Boy's Workshop | Frontispiece |

| OPPOSITE PAGE | |

| Treatment of a Boy's Room | 58 |

| Fig. 64.—A Colonial Doll-house | 78 |

| Fig. 96.—Another Style of Doll-house} Fig. 97.—Interior View of Doll-house } | 90 |

| An Amateur's Outfit | 128 |

| A Group of Amateur Papers | 142 |

| Fig. 168.—A Handy Dark-room } Fig. 172.—A Washing-box and Drying-rack} | 154 |

| In Camp for the Summer | 175 |

| A Boys' Log-cabin | 188 |

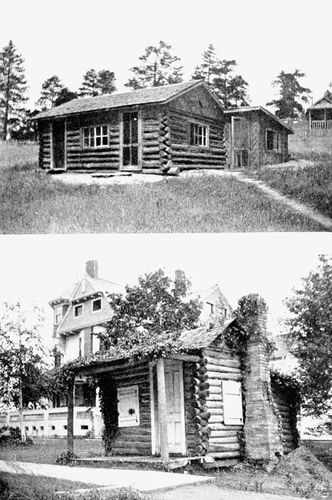

| Two Simple Cabins | 198 |

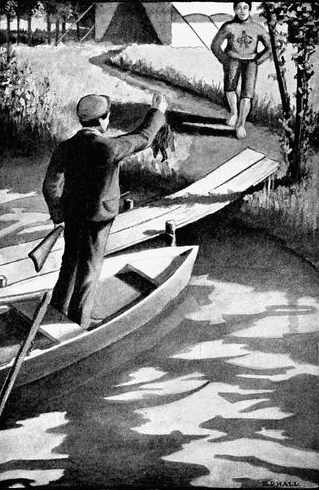

| Caught at Last | 226 |

| The Back-yard Circus | 268 |

| A Miniature Theatre | 303 |

| Fig. 330.—A Field Scene } Fig. 338.—A Blockhouse Scene} | 316 |

| Fig. 339.—A Street Scene | 320 |

| Fig. 375.—The Car completed} Fig. 376.—The Framework } | 344 |

Carpenter work should be encouraged in a boy from the time he first becomes interested in it, for besides being something with which to keep him busy, the experience gained by its practice will be useful to him all his life, no matter what branch of industry he may follow later on.

When a boy has learned the proper care and use of tools, and is able to turn out neatly executed work, he will find the occupation a profitable one, there being an unlimited number of things he can make in his shop.

Doll-houses for girl relatives, toys for brothers and cousins, and articles for the household, such as are described in following chapters, are a few of the many things he can construct. Many of these are salable articles, besides being suitable for birthday and Christmas gifts, and should bring a neat sum of money to the young carpenter.

A knowledge of carpenter work also develops in a boy a handiness for devising and putting together articles and apparatus for his own use.

[Pg 4]A boy should really have a shop where he can keep his tools and unfinished work with no danger of them being disturbed, and where he need not be afraid of littering the floor with shavings or of making too much noise.

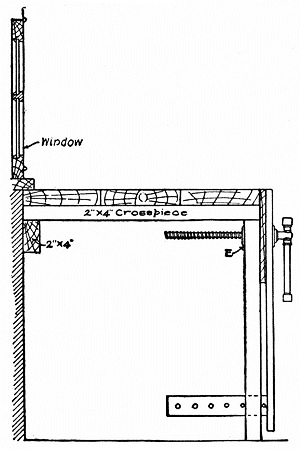

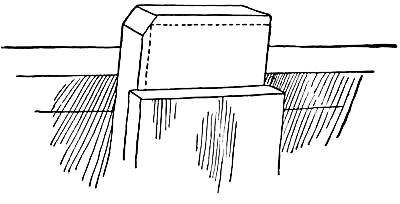

Fig. 1.—End View of Work-bench.

The Workshop may be fitted up by the boy himself, and a suitable place can probably be found in the basement, barn, or woodshed. Here a corner large enough to contain a work-bench, carpenter's horses, and tool-cabinets, besides plenty of room to work in, should be partitioned off, and a window that will admit a good supply of light made in one side of the room, if one has not already been provided.

A Solid Work-bench, six feet long, thirty inches wide, and thirty-two inches high, should be constructed beneath the window. It is a good idea to build this on to the wall if possible, as it is easier to make a solid bench by doing so, and the firmer it is, the better.

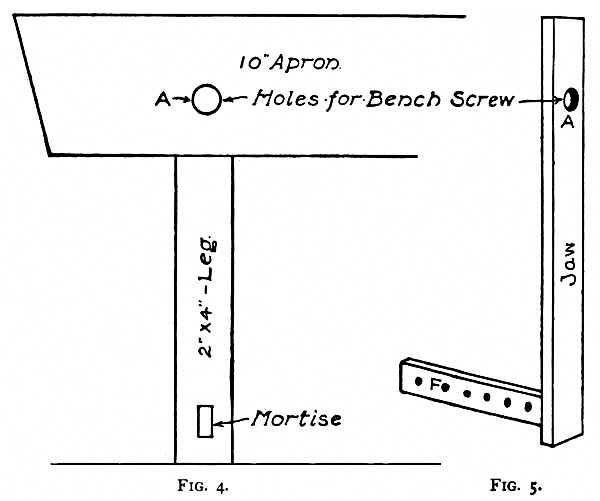

First cut a two-by-four[Pg 5] four feet long, and spike it to the wall below the window, twenty-eight inches above the floor. Then saw two pieces of two-by-four, twenty-eight inches long, for the legs, and two pieces, thirty inches long, for crosspieces. Spike the crosspieces on to the legs and on to the piece nailed to the wall, as shown in Fig. 1. Cut three ten-inch planks, six feet long, and spike them to the crosspieces so that they project twelve inches over the ends, but are flush with the framework in front. Then cut a ten-inch board, six feet long, for an apron, and, after cutting the ends as shown in Fig. 4, nail it across the front of the bench.

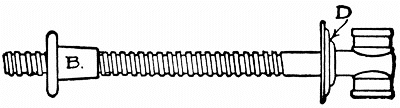

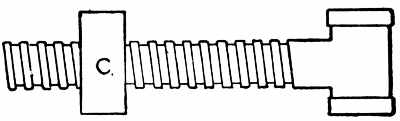

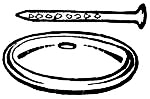

For fifty cents a fifteen-inch iron or wooden bench-screw, similar to those in Figs. 2 and 3, can be purchased at a hardware store, and the rest of

The Vise is simple to make. Figures 1, 4, and 5 show the details for this.

Fig. 2.—Iron Bench-screw.

Fig. 3.—Wooden Bench-screw.

Take a board thirty inches long by six inches wide for the jaw, and bore a hole a little larger than the screw, six inches from one end. Bore another hole the same size through the apron and table-leg, six inches below the[Pg 6] bench-top (see A in Figs. 4 and 5). The portion of the iron screw marked B in Fig. 2 should be set into the hole bored in the bench-leg and screwed at E (Fig. 1), while the portion D is to be screwed to the jaw. If a wooden screw is used, the portion C in the drawing (Fig. 3) is nailed to the inside of the bench-leg.

Figs. 4-5. Details of Bench-vise.

In order to guide the bottom of the jaw, an arrangement similar to F in Fig. 5 should be made. Make a mortise two inches long by one inch wide near the[Pg 7] bottom of the bench-leg and cut a strip of wood fifteen inches long to fit loosely in it. Then shut the vise and mark upon the inside of the jaw the place where the mortise comes in the leg. Nail one end of the fifteen-inch strip to the jaw at this point, being careful to get it in such a position that the other end will slide into the mortise. Bore several holes in the strip and cut a peg to fit in them. The jaw can now be kept parallel with the side of the bench by adjusting the peg, which is very necessary in order to have the vise grip a piece of work squarely.

When you have a long board to work upon, it cannot be held steady by the vise alone. One end should be placed in the vise and the other rested upon a peg stuck in a hole bored in the side of the bench. For boards of different lengths, several holes should be bored, as shown in the illustration of the finished bench (see frontispiece), and a movable peg cut to fit in them.

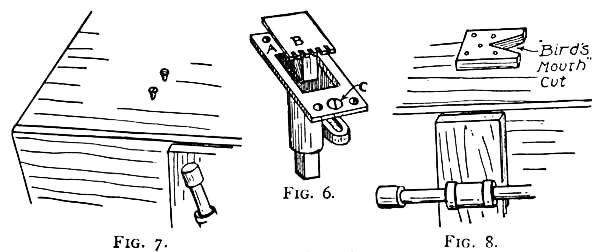

A Bench-stop of some sort fastened to the top of the bench will be found useful to push work against while planing it, when it is not convenient to use the vise. Figures 6, 7, and 8 show the forms of stops most commonly used by carpenters. Of these the metal stop shown in Fig. 6 is the most satisfactory, as it can be adjusted to different heights. It costs but little and is easily put in place. A mortise is made in the top of the bench to receive the lower portion of the stop, and the plate A is set flush with the bench-top and held in[Pg 8] place with screws driven into the holes in the corners. The centre of this plate (B) is detached from the rest and mounted upon a small post, which can be adjusted to the desired height by giving the screw at C a few turns with the screw-driver. The teeth in the edge of B help to hold the work in position.

Figs. 6-8.

Some Forms of Bench-stops.

One of the simplest forms of stops is shown in Fig. 7. It consists of two screws placed in the top of the bench, which can be raised or lowered with the screw-driver to the height you desire.

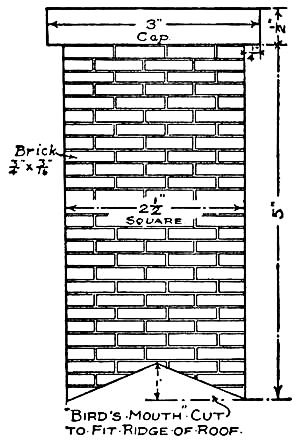

The stop shown in Fig. 8 is made out of a block of wood with a "bird's mouth" cut in one side. It should be nailed to one end of the bench in such a position that the end of the work can be placed in the "bird's mouth."

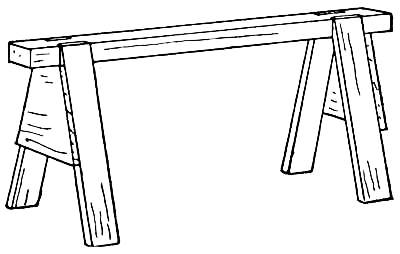

While most of your work will be done on the bench, and a good portion of sawing done with the wood in the vise, large pieces, especially long boards, are generally sawn while placed across horses.

[Pg 9]

Fig. 9.

Two Carpenter's Horses will be required. A good scheme for these is shown in Fig. 9. The top is made out of a piece of two-by-four with bevelled mortises cut in two sides of each end as in Fig. 10. These mortises are made to receive the legs, and the angle of the bevel will of course determine the angle at which the legs will spread. Cut the legs out of four-inch boards, and bevel the lower ends to make them set solidly upon the floor. Nail the legs firmly in place and brace them with two boards cut and fitted in place, as in the illustration. When the pieces have been nailed together, plane off the tops of the legs to make them flush with the top of the horse, and trim the lower ends if they require it until the horse is solid.

Fig. 10.

Boring, paring, and nailing on the bench will soon make the surface uneven, unless something is placed beneath the work during such operations. You should therefore make and use

A Bench-hook, such as shown in Fig. 11. A good size is ten by twelve inches, but it may be made[Pg 10] larger or smaller if desired. Nail a strip along one edge of the under face and another strip along the opposite edge of the upper face. The latter strip should have three kerfs cut in it as shown in the drawing, one at right angles and the other two at forty-five degrees. These may be laid off with a try-square, as shown in Figs. 38 and 39 (Chapter II), or with the bevel, as shown in Fig. 42. Be careful to keep the saw on the line and in a perfectly perpendicular position in making these kerfs. The upper strip on the bench-hook serves the purpose of a stop, and the kerfs make it possible to use the bench-hook for mitring with the back-saw. Further description of the uses of this handy article will be found in the following chapter.

Fig. 11.—A Bench-hook.

You will need

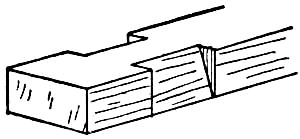

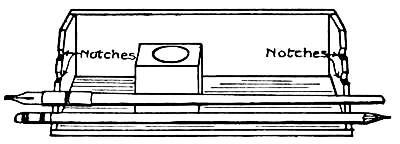

A Mitre-box for cutting mitres in large work, and[Pg 11] this may be made as shown in Fig. 12. Cut two pieces of seven-eighths inch maple, or other hard wood, twenty inches long by six inches wide, and one piece twenty inches long by four inches wide. Nail the six-inch pieces to the edges of the four-inch piece as shown in the drawing, after which you are ready to cut the mitres. These should be laid out similar to those on the bench-hook, by means of the mitred try-square or the bevel. With the blade of the try-square or bevel extending across the top edges of the side-pieces, mark off forty-five degree lines at A and B, and a ninety degree line at C, after which square the lines down both inner and outer face of the side-pieces. When the lines have been accurately drawn, it is a simple matter to make the kerfs, if you have had any practice in sawing and can keep to a line.

Fig. 12.—A Mitre-box.

No matter how skilful a carpenter is with his tools, he generally depends upon his mitre-box in making mitres, for not only accuracy is obtained by its use, but time is also saved. In using one be careful not to let the saw cut into the sides of the kerfs, or the box will soon be rendered useless for making accurate mitres.

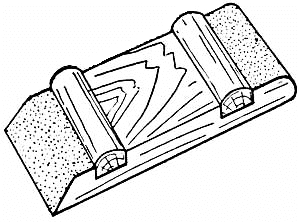

Before putting the finish upon a piece of work, the wood should be thoroughly sand-papered. In many[Pg 12] cases certain portions cannot be reached by the hand, and so

A Sand-paper Block similar to Fig. 13 should be made. Cut a block of wood five inches long, two and one-half inches wide, and seven-eighths of an inch thick. Then place it in the vise, and bevel one end and round the other as shown in the drawing. An inch and one-half from each end cut "rabbets" one inch wide across the block, and make two blocks to fit them. When this has been done, cut a strip of sand-paper two and one-half inches wide and stretch it around the block, holding it in place by driving the small blocks into the rabbets. You will find this sand-paper block very handy, as some portion of it can be got into almost every corner you will ever have occasion to sand-paper. The paper may be quickly replaced with a fresh piece when worn out.

Fig. 13.—Sand-paper Block.

A Strop for putting keen edges on tools may be made out of a block of wood, with a piece of shoe-leather, or section of an old razor-strop, glued to one side of it.

A Plumb, similar to Fig. 14, is a handy article to have for outdoor work, such as erecting posts in perpendicular positions. You will have need of it in putting up such buildings as the back-yard club-house, the log-cabin, and the erection of apparatus for the outdoor gymnasium, the construction of which will be found in following chapters.

[Pg 13]It consists of a stick, the sides of which have been planed up true and parallel, with a notch in one end and a cord with a weight attached fastened to the other end. The notch should be cut in the exact centre of the end of the stick, and the nail placed in the other end directly in line with the centre of the notch. An iron nut, or some such weight, should be attached to the lower end of the cord.

By placing this stick at the side of an object, you can determine whether or not it is plumb by the position of the string, which should hang in the centre of the notch when the object is plumb. The length of the stick may be made to suit the size of the work it is to be used upon. Four or five feet is a good length for ordinary outside work.

Fig. 14.

In purchasing Tools for your workshop it is not advisable to buy them in chests, for they are almost always made of cheap material, and poor tools are of no use to the boy who intends to do good work. It is a much better plan to buy a few tools at a time, getting a good quality of steel, and to gradually increase your outfit as your money permits. Then if you really want a chest you can make it yourself. A hatchet, hammer, saw, plane, chisel, jack-knife, bit and bit-stock, screw-driver, and square are the principal tools you will require, and need be all you have to start out with. Others[Pg 14] may be got as you have need of them, and may be selected from the following list, which includes probably all the tools a boy would ever have occasion to use.

LIST OF TOOLS FROM WHICH TO MAKE YOUR SELECTIONS

1 14-inch Jack-plane.

1 18-inch Fore-plane.

1 9-inch Smoothing-plane.

1 22-inch Rip-saw.

1 20-inch Cross-cut saw.

1 12-inch Back-saw.

1 12-inch Compass-saw.

1 Gig- or Bracket-saw.

1 Ratchet Brace.

5 Auger-bits, ¼-inch, ⅜-inch, ½-inch, ¾-inch, and 1-inch.

1 Expansive-bit.

Several Gimlet Bits.

1 Screw-driver Bit.

1 Countersink.

1 Brad-awl.

2 Hand Gimlets.

1 Automatic-drill.

4 Chisels, ¼-inch, ½-inch, ¾-inch, and 1-inch.

2 Gouges, ⅜-inch and ¾-inch.

1 Draw-knife.

1 Jack-knife.

1 Hatchet.

1 Hammer.

1 Tack Hammer.

1 Mallet.

2 Nail-sets (large and small).

1 Hand Screw-driver.

1 Wood Rasp.

1 Metal File.

1 Pair Cutting Nippers.

1 Pair Pincers.

1 Grind-stone.

1 Oil-stone and oil-can.

1 Strop.

1 2-foot Folding Rule.

1 Large Steel Square.

1 7-inch Try-square.

1 Bevel.

1 Marking-gauge.

1 Compass.

The proper care and handling of these tools is fully described and illustrated in the following chapter. These directions should be carefully read before you attempt to use the tools, especially the edge tools.

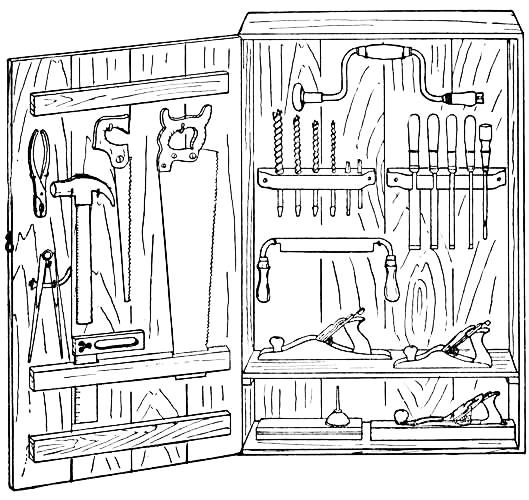

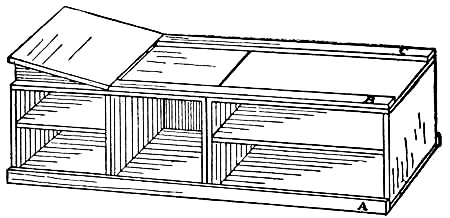

A Cabinet will be found much better for an outfit of tools than a tool-chest, as it can be more easily got[Pg 15] at than a chest, where it is necessary to lift several trays before you can reach a tool which has been put in the bottom.

Fig. 15.—Tool-cabinet.

The cabinet shown in Fig. 15 is made out of a box about three feet long, two feet wide, and nine inches deep. Make a door from the box-cover, fastening the boards together by means of two battens placed at the top and bottom (see illustration). Nail a cleat on[Pg 16] each side of the cabinet six inches from the bottom, and make a shelf to fit upon them.

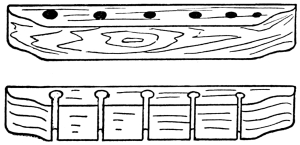

Racks for Bits and Chisels should be made similar to Fig. 16, and fastened side by side to the inside of the cabinet.

Cut a strip of wood about the size of the battens, and make two slots in it, one for the end of the saw to fit in and the other for the blade of the try-square (see Fig. 15). This strip is fastened to the cabinet door a few inches above the bottom batten.

Fig. 16.—Bit and Chisel Racks.

Hang up the other tools on brass hooks.

After completing the cabinet, paint it inside and out, and fasten either a hook or lock to the door.

When this cabinet becomes too small for your increase in tools, you can keep those you use the most in it, and make

Another Cabinet for the special and less used tools. Either screw the cabinets to the wall or support them upon brackets.

Racks may be made for any tools you wish to hang on the wall. A piece of grooved siding nailed above the bench will do nicely for the large square.

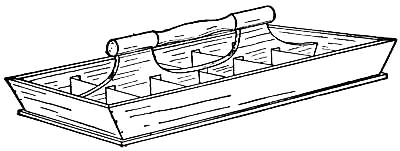

When you do outside work you will want something[Pg 17] in which to carry such tools as will be required to complete the job.

Fig. 17.—A Carpenter's Carrying-box.

A Carpenter's Carrying-box should be made. Such a box is shown in Fig. 17. The box should be about twenty-seven inches long to accommodate the saws, and it would be well to make the width eight inches and the height sixteen inches. First prepare the end-pieces, making them six by sixteen inches and rounding the tops with the compass-saw, as shown in the illustration. Then cut a board twenty-five inches long by six inches wide for the bottom and nail the end-pieces to the ends of it. Make the side-pieces twenty-seven by eight inches, and nail them to the end-pieces and to the edges of the bottom board. The handle consists of a broom-stick fitted into holes bored near the tops of the end-pieces.

This box should be used for tools only, and not have[Pg 18] nails, screws, and bolts mixed up with them, for these supplies should be kept in a special

Nail-box, with compartments for the different sizes of nails, screws, hooks, screw-eyes, hinges, etc. One of the best kinds of boxes for this purpose is a knife-box such as can be bought for ten or fifteen cents. This is divided in two and has a handle attached (see Fig. 18). The two compartments should be sub-divided into smaller boxes, either with pieces of cigar-boxes, or with pieces of tin bent at the ends and fastened to the sides of the box, as shown in the illustration.

Fig. 18.—Nail-box.

Supplies of nails, brads, etc., should be kept in cans and cigar-boxes of different sizes, and it is a good idea to letter these receptacles that you may be able to put your hands upon what you want without having to hunt for it.

Shelves will be handy to keep paint-cans and these boxes on.

Workshop Clothes.—Old clothes should be worn in the shop, as carpenter work is rather hard upon them, especially[Pg 19] the trousers. Better than these is a pair of overalls and perhaps a jumper. They are easy to work in and wear better than anything else.

A Few Hooks should be placed on the wall for hats and coats, and for your working clothes, if you change them in the shop before and after work.

To prevent your tools from being carried off, and your work from being disturbed, it is advisable to have a lock upon the door and keep your shop locked up when you are away.

To avoid danger of fire, keep combustible articles, such as oily waste and rags, in covered tin cans, and do not allow shavings and rubbish to accumulate.

Before using a tool be sure you understand the proper handling of it, for there is probably nothing more easily injured than an edge tool in a sharpened condition. An inexperienced person is very apt to dull or nick a tool by striking its edge against nails or by using it for purposes other than what it was made for. For this reason a carpenter is very apt to refuse a boy, or any amateur for that matter, the use of his tools, and he is right in doing so. Just imagine the amount of work it makes for him to put the tools in shape after they have been returned in all sorts of conditions. A little rubbing on the oil-stone, with an occasional grinding, is all his tools require when he is using them, but to remove nicks made by his young friends wastes too much of his valuable time.

A good rule to observe, boys, is never to lend tools to any of your friends, for though they may be as careful in handling them as you are, the chances are they will not be. You had better be a little "grouchy" in this respect, than to have tools which are unfit to do good work with.

[Pg 21]The following directions, together with the illustrations, should make the handling of your tools perfectly clear, and you will find among these a number of hints as to the care of tools that should be carefully adhered to in order that you may keep them in good condition.

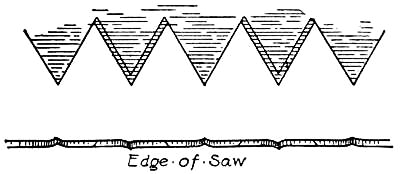

Fig. 19.—Teeth of Cross-cut Saw.

Saws.—A boy can get along with two saws, a cross-cut saw for general use and a compass-saw for finer work, such as circular sawing, and cutting thin wood where a large saw would be too coarse and apt to split the work. But you will often have need of a rip-saw, back-saw, and bracket-saw. They were therefore included in the list of tools on page 14, and you can add them to your outfit as your money permits.

The Cross-cut Saw is, of course, intended for cutting across the grain, while the rip-saw is for cutting with the grain, or ripping. The former saw can be used for rip-sawing, but the operation is much slower, and when you have much of it to do, as in ripping a six-foot board, for instance, you will find the work tedious.

The Rip-saw is not fit for cross-cutting, as it leaves the cut fibres in a very rough condition.

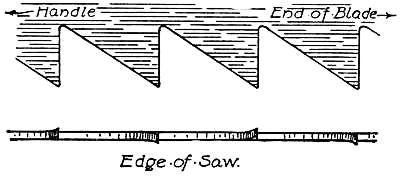

The difference in these two saws lies in the shape of their teeth. This can be seen by picking them up and examining their cutting edges. You will find the teeth are bent out of line, the first to the right side and the next to the left. This is known as the "set" of the teeth, and the quality of your work will depend largely[Pg 22] upon the care with which the teeth have been sharpened and set. At first you may confuse these two saws, but if you will notice that the teeth of the cross-cut saw come to sharp points and are bevelled on the sides, while those of the rip-saw are not sharpened on the sides, and instead of being pointed on the ends are chisel-shaped (see Figs. 19 and 20), you will have little trouble in distinguishing them.

Fig. 20.—Teeth of Rip Saw.

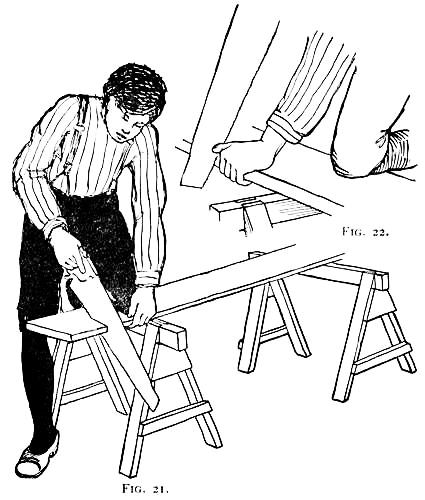

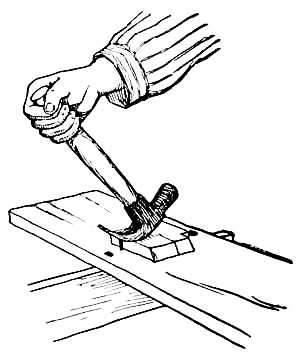

Sawing.—Small pieces may be sawn while held in the vise, but, as a rule, large work is placed across a couple of horses. It is generally the most convenient way. Grasp the saw in the right hand, and take the position shown in Fig. 21, with the left knee upon the work to hold it in place, and the left hand at the edge of the board. The thumb should be pressed against the saw-blade to guide it until the cut has been well started, as shown in Fig. 22. Without the aid of the thumb the saw is liable to slip off the mark and make an ugly cut in the wood. First use[Pg 23] a few short strokes until the saw has started to cut. Then use a long, steady stroke, putting all of the pressure upon the down stroke. Be careful to keep the saw to the line and in a perpendicular position, so that the cut will be square on all sides. If it starts[Pg 24] to run away from the line, a slight twist of the blade will return it.

Figs. 21-22.—Position for Sawing.

When a board has been sawn nearly in two, remove the weight of your knee from it, and hold the board with the left hand to prevent it from splitting off.

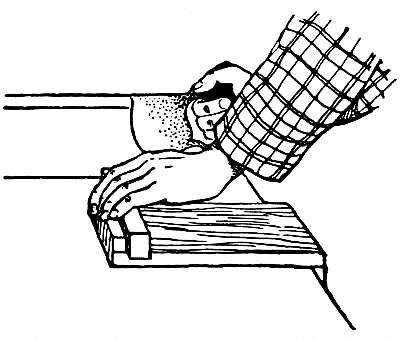

Fig. 23.—Position for using the Back-saw.

Fig. 23 shows the correct position for using

The Back-saw, which is intended for more delicate work than the larger saw, such as can be sawn on the bench-hook or in the mitre-box. It makes a finer cut, its teeth being smaller and more closely set.

The blades of

The Compass-and Gig-saws are small and narrow, the former being used for circular cutting, as the name would imply, while the latter is employed in cutting very thin wood and in making delicate curves. The blades of these saws, especially the latter, are easily broken, and must be handled with care. The teeth are arranged so as to cut with and against the grain.

The slot made by removing the fibre of the wood in sawing is known as

[Pg 25]A Kerf. The term is used a good deal in carpenter work, so it is well to know its meaning.

The carpenter of to-day is generally supplied with all manner of planes,—rabbeting-planes, beading-planes, circular-planes, ploughs, etc.,—besides the more commonly used jack-plane, fore-plane, and smoothing-plane. Each of these planes has a special form of work to do, but ordinarily a boy will have occasion to use but the last three named, and many get along with but a jack- and a smoothing-plane.

The Jack-plane is the plane you will first need to remove the rough surface of undressed lumber, and also to reduce quickly the thickness of wood. The cutting edge of the blade is ground so as to gouge the wood, removing thick shavings, but leaving ridges and hollows which must afterward be removed by a fore-plane or smoothing-plane. There is one trouble in using the smoothing-plane for this operation, however, and that lies in the danger of it following the hollows formed by the jack-plane, making a smooth but uneven surface.

The Fore-plane, on the other hand, has a long enough stock to prevent the blade from cutting the lower portions until the high portions have been removed. Although a fore-plane can be used alone for smoothing large work, it is more convenient to finish up with

The Smoothing-plane.

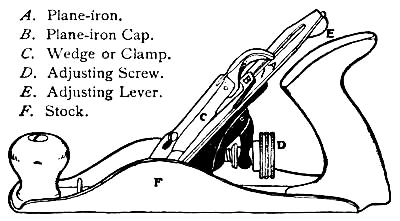

The Stanley iron plane, shown in Fig. 24, is a great improvement over the old-style wooden ones, and is the[Pg 26] most popular plane used to-day. It is more easily handled, as its iron is quickly put in place and adjusted. The illustration gives the names of the various parts. The cap (B) is screwed to the plane-iron (A), and both are held in the stock (F) by means of the clamp on the end of the wedge (C). The thumb-screw (D) regulates the degrees of fineness of the plane-iron, while the lever (E), which moves from side to side, straightens the position of the iron. The base of the stock is known as the sole, or face.

Fig. 24.—Stanley Iron Plane.

A. Plane-iron.

B. Plane-iron Cap.

C. Wedge or Clamp.

D. Adjusting Screw.

E. Adjusting Lever.

F. Stock.

The Bailey plane is somewhat similar to the Stanley, the upper portion being of iron with screw adjustment, but the base being of wood. Its cost is much less than that of the entire iron plane, and you will probably find it as satisfactory if you do not care to spend the additional amount for the Stanley plane.

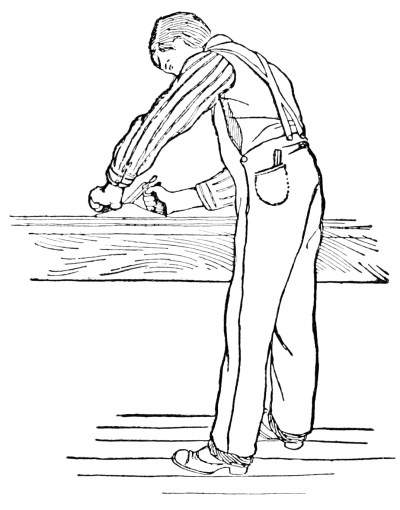

For Planing, take the position shown in Fig. 25, with the left foot a little in advance of the right, the right hand grasping the handle of the plane and the left holding the knob on the fore part of the stock. Use a long, steady sweep, and bear with equal pressure from the beginning of a stroke to the end, to avoid the hollows that are so easily made by taking shavings of different thicknesses.[Pg 27] Do not drag the plane-iron over the work in returning it for another stroke, as it will dull its edge.

You will often come across wood with a crooked grain, which runs diagonally through the piece, terminating at the surface. There is a right way and a wrong way in planing this, just as there are two ways of stroking a cat's back, one smoothing the surface, while the other roughens it. When you find a piece of wood with this kind of uncertain grain, you will probably have to change the direction of your planing a number of times before finishing the surface, in order to plane with the grain.

Fig. 25.—Take this Position for Planing.

In planing end-wood, you will have trouble in preventing the corners of the piece from splitting off unless it is placed in the vise in front of another block of wood, the planing being done toward the block. Or one[Pg 28] corner may be chamfered with the chisel, as shown in Fig. 29.

Testing Work.—It is necessary to test work frequently while planing, in order to locate the high places and avoid taking off too much on the low places. This may be done by squinting one eye and holding the board on a level with the other eye, so that you can look down the length of it as in sighting a gun. The uneven places show up very plainly in this way.

Work is also tested by means of the try-square. Place the handle of the square against the edge of the work with the blade of the square extending across the planed surface, and move it the length of the board. Any irregularities in the surface will show themselves as the blade passes over them. In planing up a block of wood, plane up one side and, after proving it to be true, use it for the "tried edge," testing the other sides with the handle of the square pressed against its surface.

There are a number of forms of

Chisels, but the only two classes you will probably ever be in need of are the firmer-and framing-chisels. The former are intended for hand use only, while the latter are used for heavier work, such as mortising, where it becomes necessary to use the mallet.

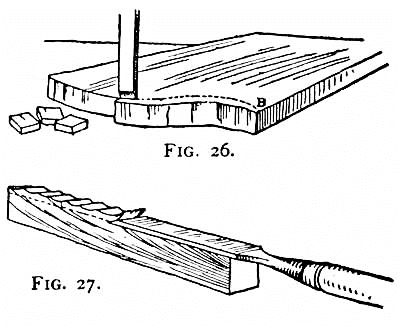

Figs. 26 and 27.—Paring.

In Using a Firmer-chisel, the work should be placed in the vise or be otherwise held in position, that both hands may be kept upon the tool, the right hand grasping the upper end of the handle and doing the pushing, while[Pg 29] the left hand holds the lower part of the handle and acts as a guide in working it.

Paring with the chisel consists in trimming a piece of wood to a given line. It is an operation very often resorted to in finishing the end of a piece of work instead of planing, and in trimming up a curved edge such as is shown in Fig. 26. Here the line AB represents the line of the finished end of a piece of work. The board is first placed in a vise and the wood removed to about one-quarter inch of AB with a compass-saw, following the curve of the line as nearly as possible. Then lay the piece upon the bench-hook (Fig. 11, Chap. I), and pare to the line with the chisel, as shown in Fig. 26.

The chisel is often used to pare down the surface of a piece of work to a given line, as shown in Fig. 27.

Fig. 28.—Bevel.

The Framing-chisel should be held in the left hand, and the blows dealt upon the handle with the mallet in the right hand. In handling the framing-chisel the bevel of the blade should be toward the work, which is just the opposite from that shown in Figs. 26 and 27. Unless this is done the chisel will not cut down squarely[Pg 30] but will cut in under, as it cannot be guided as easily as the firmer-chisel can, with both hands to hold it.

Chamfering and Bevelling are somewhat similar operations. They consist in cutting the edges of a piece of wood, as shown in Figs. 28 and 29.

Fig. 29.—Chamfering.

The corner of a block of wood is very often chamfered, when planing end-wood, to prevent the wood from splintering. It can only be done, of course, before the adjoining side has been planed up, that a square corner can be obtained again when the work is finished.

The Gouge is a chisel with a curved section, its use being for cutting grooves and curvatures in a piece of work where the chisel cannot be employed.

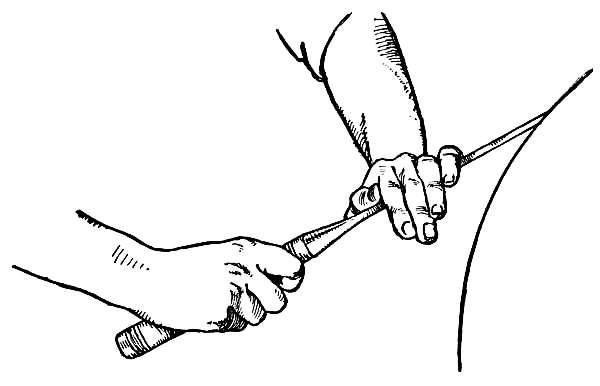

A Draw-knife is very handy for quickly reducing the size of material and in rounding sticks. The blade is drawn toward you instead of being pushed as in the case of a plane or chisel.

Boring.—Probably the only trouble you will have with the bit and bit-stock will be in holding the brace in a perfectly vertical position so as to bore a straight hole.

[Pg 31]The centre of the hole should first be located upon the work. Then, after selecting the right size of bit and securing it in the clutches of the bit-stock, grasp the handle of the stock with the right hand and place the left hand on the top knob. Set the point of the bit against the work and bore steadily until the point appears upon the opposite side. The bit should then be withdrawn and the rest of the hole bored from the other side. This prevents the fibre around the hole from splintering off, as it is likely to do when a hole is bored all the way through from one side. To bore a hole in a piece of work held in the vise, clamp a waste piece of wood in the vise with it, and bore straight through the work into the waste piece.

When boring hard wood or using large bits increased pressure is necessary to operate the brace and at the same time steady the bit. This can be obtained by allowing the chest to bear upon the top knob.

Holes two inches or more in diameter do not require a bit that size, for smaller holes can be bored and these trimmed to the required opening with a chisel or with the keyhole-saw. Whatever style of bit-stock you buy, get one with a fair length of arm, as a good leverage cannot be obtained with a short one.

An Automatic-drill is a handy tool to have in the shop, although not a necessity. You have probably seen carpenters use it in drilling holes in hard wood, before driving in finishing nails or screws. It beats the awl and[Pg 32] gimlet for speed, and is a tool which can be used in places where neither of these could be operated. The handle of the tool contains a number of sizes of drills.

This tool must be used with care, as the drills snap off very easily when the tool is handled roughly or twisted from side to side while boring a hole.

The Hatchet is an indispensable tool, for it can be used for a good deal of your rough work, such as splitting and paring. It requires practice to handle one successfully, however. A misplaced blow will sometimes ruin your work, either by cutting into it or striking grain which runs off into the portion to be finished. With straight grained wood it is not so difficult to pare to a line with the hatchet. The wood should be removed to within less than an eighth of an inch of the line, as the work must be dressed up afterward with the plane.

It is well to have

A Hammer with a fairly heavy head for large work, and a lighter one with which to drive small nails.

Fig. 30.—Withdrawing Nails.

Driving Nails.—The nail should first be held in position with the thumb and first two fingers, and given a few light raps with the hammer to start it. Then remove the fingers, and drive the nail home with steady blows, being careful to hit the head squarely so it will not bend.

Although a bent nail can be driven home with the proper stroke, it is generally easier and quicker to withdraw it and either hammer it out straight or use another.

[Pg 33]A pair of pincers are handy for

Withdrawing Nails, especially nails whose heads are too small to be gripped with a claw hammer; but for removing large nails a stronger leverage is necessary. This can be obtained as shown in Fig. 30. The head of the nail is gripped in the claw of the hammer and a block of wood placed beneath the head. The handle of the hammer is then pulled toward you, as shown in the illustration. The block, besides increasing the leverage, prevents the hammer-head from injuring the surface of your work, and makes it possible to withdraw the nail in a fairly straight condition.

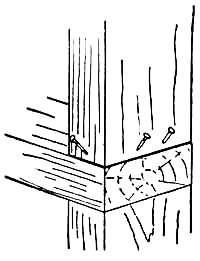

Fig. 31.—Toe-nailing.

Toe-nailing consists in driving nails diagonally into a piece of wood. It is used in fastening the ends of uprights, as shown in Fig. 31, where the nails cannot be driven in any other way, and also where there is danger of a board springing. You will often find it convenient to use this form of nailing[Pg 34] when the nails are too long to be driven straight into the work.

Blind-nailing is a form of toe-nailing used on tongue and grooved boards in which the heads of the nails are concealed below the surface, as shown in Fig. 32.

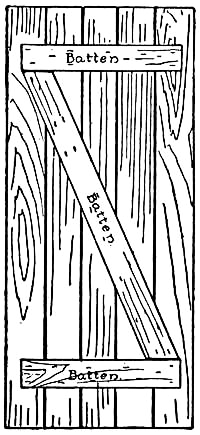

Clinching.—When nails come through a piece of wood their ends should be clinched. This is done by having some one hold a hard surface, such as the head or blade of a hatchet, against the under side of the work, or by laying the hatchet down and resting the work upon it, while you drive the nail. The point of the nail will bend over when it strikes the hard surface and sink into the wood. This is the best method to use in fastening boards together with battens, in rough work, as the clinched nails act as rivets, preventing any possibility of the boards pulling apart.

Fig. 32.—Blind-nailing.

Do not drive the head of a nail into a finished surface with the hammer, as you are likely to mar the wood in doing so. Leave this—the "setting" of the nails—until the piece of work has been put together. Then go over it and drive the heads below the surface with

The Nail-set, holding the tool as shown in Fig. 33. The holes made by the heads should be filled up with putty before the finish is put upon the wood.

Before driving nails into hard wood, holes should be made with the brad-awl or drill, to prevent them from[Pg 35] splitting the wood, and to make it easier to drive them in without bending. The holes should be a trifle smaller than the nails. Always drill a hole before driving a nail into thin wood or near the edge of a piece.

A nail can be driven more easily if its point is rubbed over a piece of soap. This is something you should remember to do when nailing hard wood.

Nails.—Iron, galvanized-iron, wire, and copper nails are manufactured, but of these the wire nail is the most commonly used for all kinds of work, it being more easily handled, not so liable to snap off, and there being less danger of splitting your work with it than with the iron nails.

Fig. 33.—Setting Nails.

You will notice the iron nails have two smooth sides and two rough ones. In using these it is necessary to drive them with the smooth sides parallel with the grain, otherwise they are sure to split the work.

Nails are classified according to their shape and gauge. The only kinds you will probably ever have[Pg 36] occasion to use are the Common, or nail for all ordinary work; the Finishing-nail, with the small head used on finish work; and the Brad, or small-sized finishing-nail. You can buy these by calling for the length you require, but it is more businesslike to use the standard terms by which all carpenters know them.

The following table gives these terms, together with the length in inches:—

2-Penny Nails (1 inch long).

3 " " (1¼ inches long).

4 " " (1½ " " ).

5 " " (1¾ " " ).

6 " " (2 " " ).

7 " " (2¼ " " ).

8 " " (2½ " " ).

9 " " (2¾ " " ).

10 " " (3 " " ).

12 " " (3¼ " " ).

16 " " (3½ " " ).

20 " " (4 " " ).

30 " " (4½ " " ).

40 " " (5 " " ).

50 " " (5½ " " ).

60 " " (6 " " ).

All nails longer than three and a half inches (20d to 60d inclusive) are known as spikes.

It is desirable to have

A Screw-driver which will set in the clutches of your bit-stock, besides the ordinary kind, for it is more quickly operated, and screws can be driven in hard wood easier on account of the greater amount of leverage you get with it.

Holes should be drilled in hard wood before driving screws into it.

Screws are made with round and flat heads. The round-headed screw is a finishing screw, and its head is left exposed on the surface of the wood; but the flat-headed[Pg 37] screw should be countersunk, that is, sunk below the surface. To do this you must drill a hole before driving in the screw with

The Countersink, which is a drill made to fit in the bit-stock, and bores a hole the shape and depth of the screw-head.

Be sure you understand the process of sharpening tools before you undertake to use the oil-and grind-stones.

All tools are not sharpened alike, and you will need to know the different ways in order to get their cutting edges the right shape to serve their different purposes.

Grinding is the most difficult part of the work, and most boys have trouble with it. One fault lies in using the grind-stone too frequently, grinding the edge of a tool when it requires only a little rubbing upon the oil-stone to put it in shape, and thus wearing down the tool unnecessarily. Again, by not keeping the stone sufficiently wet, the heat produced by the friction takes the temper out of the steel, making it soft and useless until retempered.

If you have a stone with a crank arrangement, it will be necessary to have some one turn it while you control the tool. The stone should be turned toward the grinder and the tools held upward so the stone grinds against the edge instead of from it. Move the tools sideways across the stone so as to wear it down evenly and help prevent[Pg 38] the formation of ridges in the stone, which are very easily produced.

Fig. 34.—Grinding the Chisel.

Figure 34 shows the position to take in grinding

Chisels. Hold the handle of the tool in the right hand and rest the palm of the left hand upon its blade. Then lower the edge upon the stone until the bevel strikes it flatly, and bear down upon the blade with your left hand. Continue the grinding until the bright line of the dull edge has disappeared and an invisible edge has been obtained. Stop when this point is reached or the edge will become feathery and break off, necessitating regrinding. Grind upon the bevelled edge only, and hold the tool in the same relative position, to prevent the bevel from becoming rounded. The angle of the bevel should be[Pg 39] about twenty-five degrees. To keep this angle the same, it is desirable to have a rest, consisting of a board nailed to the frame of the stone, upon which to support the handle of the chisel.

Gouges and Draw-knives are ground similarly, the former being rocked from side to side, in order to grind the curved bevel uniformly.

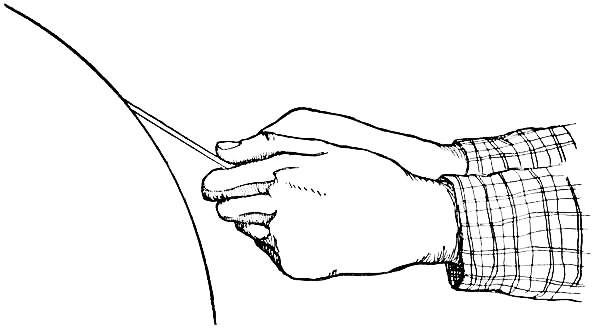

Plane-irons are held with both hands, as shown in Fig. 35, and ground the same, except that the corners of the smoothing-and fore-plane irons are slightly rounded, while the edge of the jack-plane iron is a little higher at the corners than in the centre, to give it the qualities for removing thick shavings. It is more difficult to keep the line between the bevel and upper part of the iron straight than in grinding chisels, on account of the wider blade.

Fig. 35.—Grinding the Plane-iron.

Knives and Hatchets are ground upon both sides of the blade.

Of course, the edge of a tool is left in a very rough condition by the grind-stone, and must be rubbed up on an oil-stone before it is fit to cut with.

There are many makes of whetstones, many good ones and many worthless ones. Above all things, don't buy a cheap one, for it will be impossible to obtain keen edges upon it.

One of the best stones upon the market is

The Washita Oil-stone, a Kansas stone of medium hardness, free from grit and lumps, and of good quality through and through.

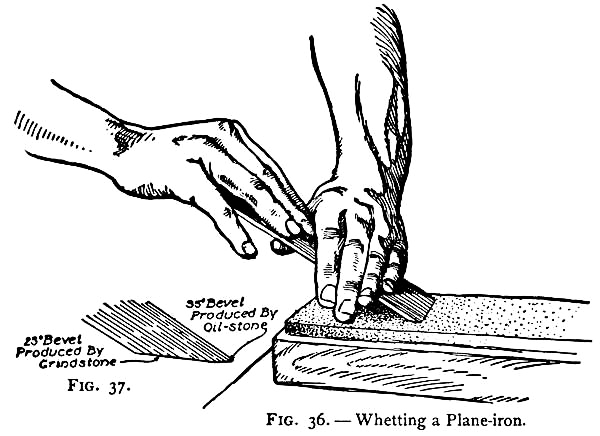

Figs. 36-37.

In rubbing up a plane-iron, grasp the end between the thumb and fingers of the right hand and place the palm of the left hand across the iron to bring the necessary pressure upon it (see Fig. 36).

Instead of holding the blade on the stone at the angle of the bevel, tip it to an angle of about thirty-five degrees, or ten degrees more than that of the bevel. With it held in this position, rub it back and forth upon the stone with a rotary motion, making a second narrow bevel along the edge of the tool (see Fig. 37). Be careful to keep the blade in the same position, to prevent the bevels from becoming rounded. By exerting a steady upward pressure against the end of the tool with the right hand, and an equal downward pressure in the centre of the blade with the left hand, this is easily accomplished.

The rough edge which appears on the back of the blade is removed by rubbing the flat side of the iron over the stone a few times. Care must be taken to keep the iron perfectly flat or a bevel will be formed.

A Strop, consisting of a piece of leather fastened to a block of wood as described in the foregoing chapter, should be used after the oil-stone, to put a fine edge upon the tool. The tool is stropped in the same way as a razor is done.

Saws require sharpening but once in a great while if proper care is taken of them. When they do become dull, or need to be set, it is advisable for you to pay an[Pg 42] experienced person to do the work rather than attempt it yourself.

A two-foot carpenter's folding-rule should generally be used in laying off measurements and a sharp-pointed pencil or brad-awl to locate the points. To connect the points it is necessary to have a straight-edge—a steel framing-square (Fig. 42) for large boards and a small try-square (Fig. 38) for smaller pieces—and a pencil or knife.

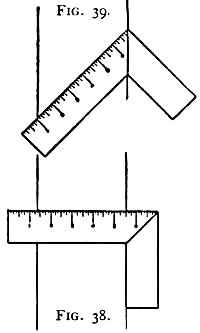

Figs. 38-39.

A pencil may be used in connecting points upon rough work, but for greater accuracy a knife should be used, as it makes a thinner and cleaner-cut line. In making knife lines, the square must be held very firmly, to prevent it from slipping and allowing the knife to run out of its course.

To draw lines across a board at right angles to one edge (which should be the straight or "tried edge" of the board) with the steel-square, place one arm of the square parallel with the tried edge and mark along the other arm. To perform the same operation with the try-square, place the handle against the tried edge, as shown in Fig. 38.

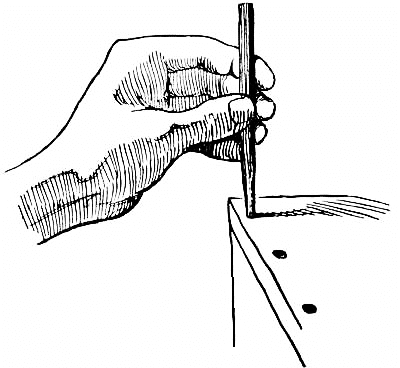

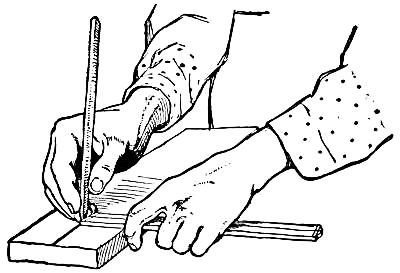

[Pg 43]Oftentimes it becomes necessary to draw a line parallel to the tried edge. This may be done roughly with the rule and pencil, as shown in Fig. 40. Grasp the rule in the left hand, with the first finger touching the tried edge of the board, and hold the pencil point against the end of the rule with the right hand. Keeping this position, with a steady hold on the rule and pencil, move your hands along the board. The result will be a line parallel to the tried edge.

At first you may have trouble in making a straight line, but with practice you will be able to hold the rule and pencil steadily.

Fig. 40.—Gauging with Rule and Pencil.

For particular work, where it is necessary to get a perfectly straight and parallel line,

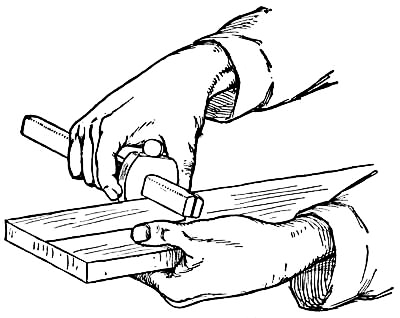

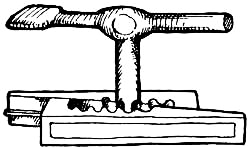

A Marking-gauge should be used. This is nothing[Pg 44] more than the above principles combined in a tool. It consists of a graduated shaft, or rule, with a small needle or spur in one end, which slides through a mortise made in a block of wood known as the head.

Fig. 41.—Using the Marking-gauge.

To operate the gauge, set the adjustable head at the required division on the shaft, and then grasp the head and shaft with the fingers of the right hand, as shown in Fig. 41. Place the outer face of the head against the tried edge of your work, and then, pressing the spur into the wood, move the gauge along the board, at the same time keeping the face of the head firmly against the edge of the board. The gauge is much more convenient than the other method of drawing parallel lines, for you can repeat the measurement as often as you wish,[Pg 45] having once adjusted the head, without having to lay it off again.

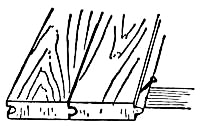

A Try-square with a mitred handle costs but little more than the ordinary make, and is much handier, inasmuch as it can be employed in making mitres, by placing the bevelled end against the side of the work instead of the straight side (see Figs. 38 and 39).

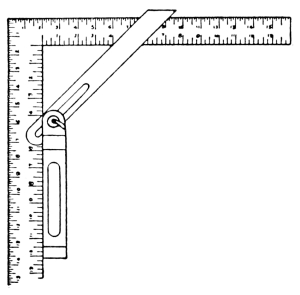

Fig. 42.

The Bevel is in reality a try-square which can be adjusted to any desired angle. To set it at an angle of forty-five degrees, place it on the steel-square, as shown in Fig. 42, with the handle against the inner edge of one arm of the square and the blade resting on both arms. Move the blade until it strikes equal distances on the arms (this is shown at four inches in the drawing) and tighten the screw while it is in this position. Other angles may be drawn out upon a piece of wood and the bevel adjusted to them so these angles can be laid off upon other pieces. You will find the bevel handy for reproducing angles. However, if you are supplied with a mitred try-square you can easily dispense with it for ordinary work.

There will be times when you wish

To Divide a Board into a number of equal parts, which may be found to be fractions of an inch that cannot be[Pg 46] easily laid off with the rule in the ordinary way. It can be accomplished with a pair of compasses, but until you become practised in their use, it will take some little time in setting them, dividing, resetting, and redividing, until the exact divisor is obtained. A much quicker method is that performed with the rule, as shown in Fig. 43.

Suppose you wish to divide a board four and three-quarters inches long into five equal parts. Place your rule across the board, as shown in the illustration, one end at one edge and the "five-inch" division at the opposite edge. Mark off the five divisions and then square the lines across the board at these points with the try-square. This will give you the required five equal parts.

Fig. 43.—Dividing a Board Equally.

In the same way longer boards may be divided up by using two-and three-inch divisions on the rule instead of one-inch, and smaller pieces by using half-and quarter-inch divisions.

There are generally repairs of some kind to be made about the house—such as mending screens, renewing window-ropes, repairing wooden walks, patching fences, etc.—which a boy can do, besides many ingenious articles for the house which he can make in his workshop. Ideas for labor-saving devices which cannot be bought upon the market present themselves now and then, and if there is a boy in the neighborhood to carry them out, the housekeeper will be only too glad to pay him for doing the work.

For general jobbing you will require a carpenter's carrying-box (Fig. 17, Chap. I) in which to carry your tools, and a nail-box (Fig. 18) for nails, screws, hinges, and such hardware as you will need upon the job. With these you will have a complete outfit.

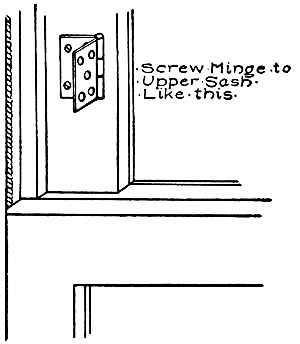

Fig. 44.—The Hinge Window Lock.

A few suggestions as to what you can do and what you can make are described and illustrated in this chapter, and should give you plenty of material to work upon when you open up your carpenter-shop. Besides these ideas, you will find most of the articles in the following[Pg 48] chapter suitable for the house and pieces of furniture for which it will be easy to secure orders.

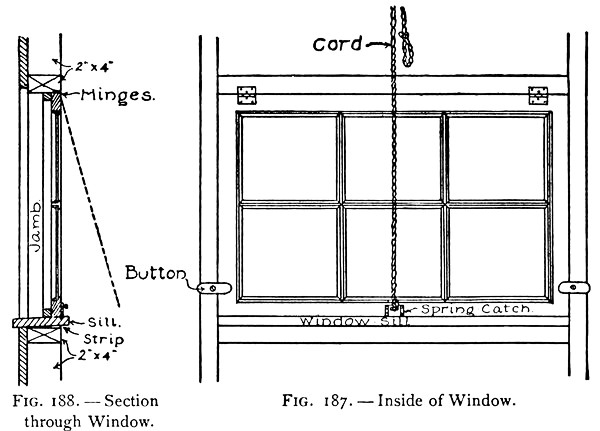

The Hinge-lock, in Fig. 44, is one of the most serviceable window-locks that can be had, for it can be so placed as to allow the window to be opened a few inches for ventilation, and at the same time prevent further opening.

The hinge is screwed to the upper sash-frame several inches above the centre sash-bar, according to the distance the window is to be opened (see illustration).

It will be seen that when the hinge is opened, as in the drawing, neither sash can be opened past the hinge; but when the hinge is folded flat it will not interfere with the opening of either sash.

This lock would probably be more extensively used if people knew how simple and satisfactory it is. As the hinges cost but a few cents a pair, and are put on very quickly, a boy should realize a fair sum of money in a short time supplying these locks.

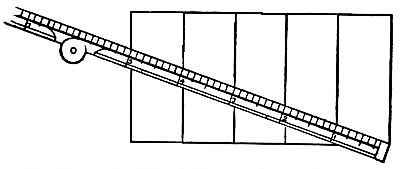

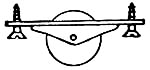

A Clothes-line Reel, such as shown in Fig. 45, is an article no housekeeper should be without. Its use does away with twisted, tangled, and knotted clothes-lines.

[Pg 49]As they require but little material, and the cost of that amounts to almost nothing, the manufacture of these time-saving devices, for the neighbors, should prove profitable.

Fig. 45.—A Clothes-line Reel.

The reel consists of two strips of wood sixteen inches[Pg 50] long by three inches wide for the sides, and two pieces of broom-handles sixteen inches long for the horizontal rods (see Fig. 45). Five inches from each end of the side-pieces, bore a hole the size of the broom-handle.

With the pieces thus prepared it is a simple matter to fit them together, as in the illustration, placing the broom-handles in the holes bored for them, and fastening them so the side-pieces are nine inches apart and a handle five inches long projects on either side. It is probably needless to say that the ends of the broom-sticks are held in the hands when operating the reel.

Fig. 46.—Broom and Dust-pan Rack.

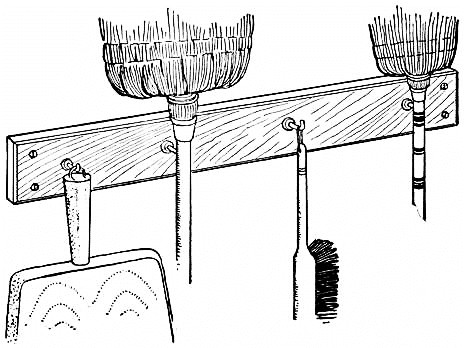

A Broom and Dust-pan Rack is a handy article for the[Pg 51] kitchen or broom-closet, and can be made as shown in Fig. 46.

A rack to hold a large and small broom, dust-pan, and brush, should measure three feet long, three inches wide, and be made out of a seven-eighths-inch board. Bevel the edges and place four brass hooks in the front, as shown in the drawing, from which to hang the broom, dust-pan, etc.

Brooms should always be dampened and put away, handle down, according to the advice of an old broom-maker, who claims that by so doing the straws are kept from becoming brittle and the broom lasts much longer. The brooms should therefore have screw-eyes placed in the handle, just above the tin binding, to hang upon the hooks, as shown in the illustration.

The rack should be screwed to the wall.

Fig. 47.—A Fly-killer.

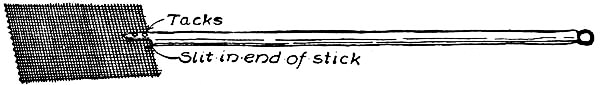

Fly-papers and poisons are deadly enemies to the house-fly, but none are as effectual or as quick acting as

The Fly-killer, shown in Fig. 47. This simple device consists of a piece of screen-wire, about four by five inches, stuck into a slot made in the end of a stick, and fastened in place with tacks driven through the end of the handle and clinched upon the under side.

[Pg 52]If possible, cut the wire with a selvage along the front edge, and trim the roughness from the other edges to prevent scratching.

The fly-killer is hung up by a screw-eye placed in the end of the handle.

Fig. 48.—An Ash-sifter.

With the fly-killer a person can strike at a fly with almost a certainty of killing it. As the screen-wire is not easily seen by the fly, and the mesh allows the air to pass through, there is nothing to alarm him.

[Pg 53]These little things are quickly made, and when you show your customer how effective they are, you will find no trouble in disposing of them.

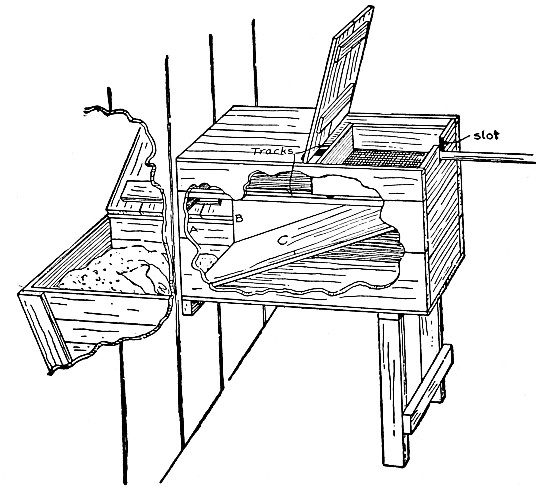

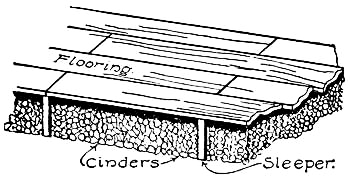

An Ash-sifter that is dust-proof and very satisfactory is shown in Fig. 48. It is made out of a packing-case about three feet long, eighteen inches wide, and twenty-four inches deep.

Set the box upon two-by-four stilts in the shed or yard (braced as shown in the illustration), in such a position that the bottom of the box will be on a level with the top of the alley ash-box. Then cut an opening through the shed wall and end of the box, as shown at AB, for the removal of ashes. Two strips are nailed to the sides of the box (seven inches below the top) for tracks for the sifter to run upon, and below this, at C, a board slide is placed to dump the ashes, which shake through the sifter, out of the opening in the end of the box into the ash-box. Nail one half of the cover to the top of the box and hinge the other half to it.

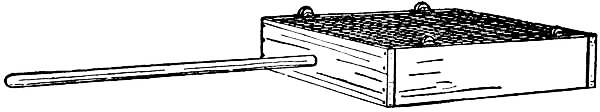

Fig. 49.—The Sifter.

Make the sifter eighteen inches square by six inches deep, using six-inch boards for the frame and one-third or one-half inch wire-mesh for the bottom (see Fig. 49)[Pg 54] Fasten four trunk-casters, such as are shown in Fig. 50, to the bottom of the frame, and fit a broom-stick in one side for a handle. A slot must be cut in the end of the box for the handle to fit in.

Fig. 50.

Trunk-caster.

A Bread-board may be made out of a seven-eighths inch maple board about ten by eighteen inches, with the surface planed perfectly smooth and the edges bevelled or rounded. A hole should be bored near one edge, so it may be hung up in the pantry.

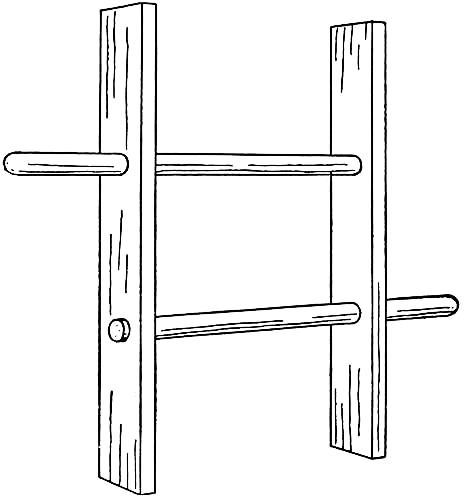

The dining-room is not complete without

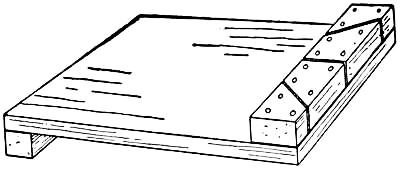

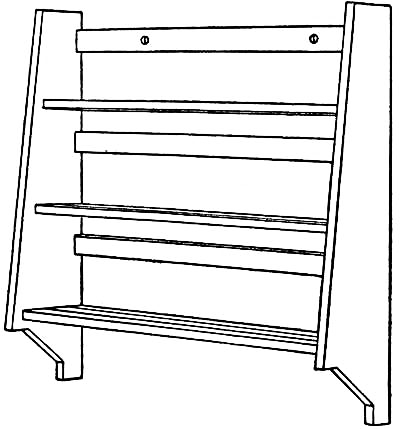

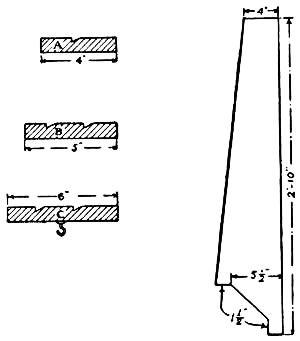

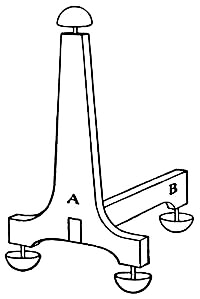

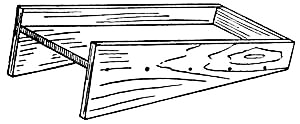

A Plate-rack for the display of pretty pieces of china. Figures 51 and 52 show the details for the construction of a rack of three shelves, and in size three feet long and two feet ten inches high. Although the design is very simple in outline, it is such as will make a pleasing piece of furniture when neatly carried out.

Fig. 51.—A Plate-rack.

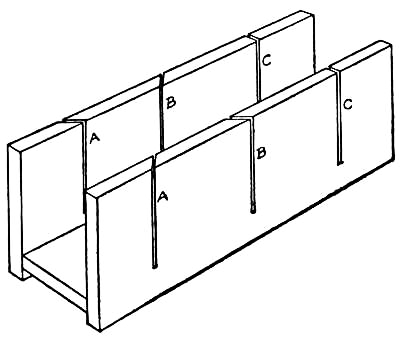

Prepare the two side-pieces the shape and size shown in Fig. 52, and cut the shelves two feet ten inches long[Pg 55] by the widths given in the drawing (Fig. 52). One groove should be made in shelf A and two in shelves B and C, for the edges of plates to stand in. These grooves are cut with a chisel, and should be made V-shaped as shown. Narrow strips of wood may be nailed along the shelves as substitutes for the grooves if you wish, but the work required to plane up the strips will amount to about as much, and they do not present as neat an appearance.

Fig. 52.

Having cut out the shelves and side-pieces, you are ready to put the rack together. For this purpose you should use finishing-nails so their heads will not make very large holes in the surface of the wood. Fasten the bottom shelf (C) between the side-pieces seven inches above the bottom, the middle shelf (B) ten inches above that, and the top shelf (A) nine inches above the middle shelf. The inner edges of the shelves should be fastened flush with the edges of the sides. In the bottom shelf place a row of brass hooks for cups to hang upon.

It is necessary to fasten three strips two inches wide between the sides in the back of the rack (as shown in[Pg 56] the drawing) for the tops of the plates to rest against. Two holes should be bored in the top strip, by which to hang the rack on nails or hooks fastened in the wall.

After completing the carpenter-work, finish the rack with a stain which will harmonize with the color scheme of the room in which it is to hang.

It is far better for a boy to spend his evenings in the house than out upon the street. He need not be without his friends there, for if he has an attractive room, with books to read, games to play, and puzzles to solve, the boys of the neighborhood will soon find it out and be only too glad to have a chance to visit him, knowing they will be sure of finding plenty of things to interest them.

The simpler the furnishings of a boy's room are the better. Plain and substantial furniture which will stand perhaps a little rougher usage than that in other rooms of the house, and handy places for storing away his traps, are what are needed.

The room should be his den where he can keep what he pleases, and arrange the fittings to suit his individual tastes. Shelves for his books and magazines, a cabinet for various collections, boxes for miscellaneous articles, and a desk at which he can study and keep his accounts, are a few of the things the room should contain. These pieces can easily be constructed in the workshop, by following the directions given in this chapter.

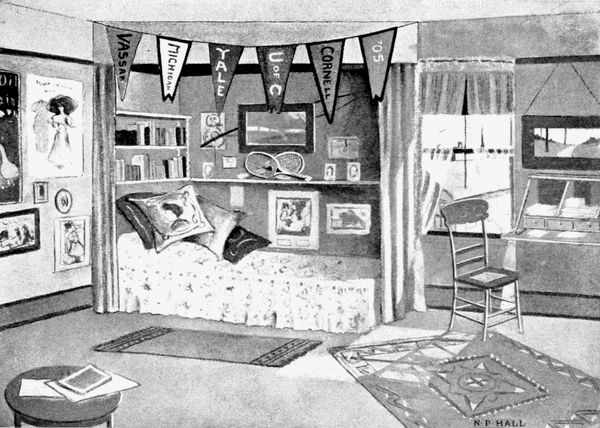

[Pg 58]On the opposite page is shown a scheme for a boy's room suggestive of his sports, games, and handicraft, and while everything is simple and inexpensive in the furnishings, it makes a room that will strike the fancy of the average boy.

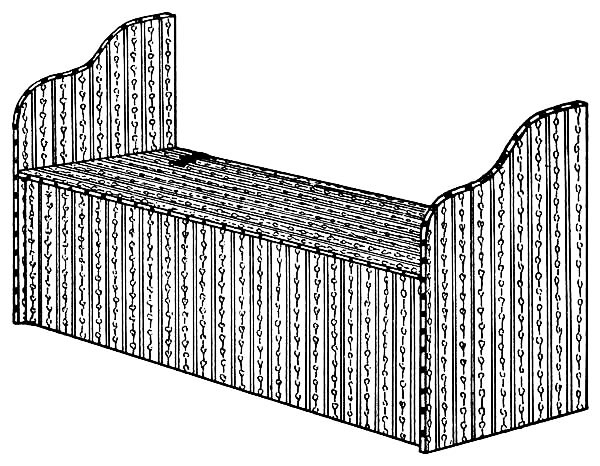

Nothing appears more attractive than

A Cosey-corner, such as shown in the illustration, and it is a simple matter to fit one up. A home-made couch, box, or seat of some sort should be constructed to set in the corner, a shelf fastened to one wall a foot or more above it, and several shelves hung on the adjoining wall, as shown in the drawing.

Purchase several yards of a dark shade of green denim, and enclose the corner with three strips (see illustration). The upper strip is stretched across the corner at the ceiling, and the other two attached to its ends and allowed to hang to the floor. It is a good idea to make also a dado of the same material within the corner from the baseboard to the under side of the shelves.

Pennants representative of the various colleges can be made out of cheese-cloth, and a string of these hung across the corner at the ceiling will produce a pretty effect.

The walls of the room may be brightened with

Small Posters, which it is an easy matter to obtain nowadays, and small pictures mounted upon colored mats and fastened behind glass by means of passe-partout paper are always attractive.

Treatment of a Boy's Room.

Picture-frames can be made out of narrow moulding, the corners of which have been mitred in the mitre-box to make them join neatly.

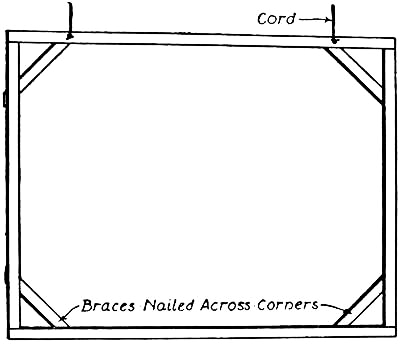

A frame which has proven satisfactory for small posters and pictures not requiring glass is one made out of common laths. The ends of the laths are not mitred as is usually the case in making frames, but are fastened together with what is known as a "butt-joint"; that is, the ends of each piece are set against the ends of the adjoining pieces. The simplest way of fastening them together is by means of small strips of wood nailed across the corners on the back of the frame.

Although this frame might be expected to have a clumsy appearance, it has not, and when thoroughly sand-papered and finished with a dull green stain is very pretty.

Fig. 53.—A Writing-desk.

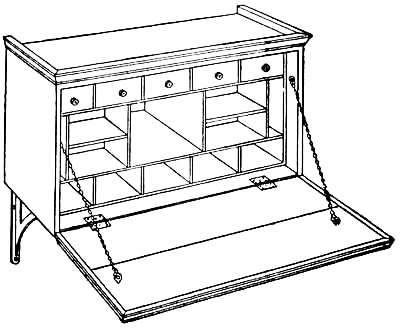

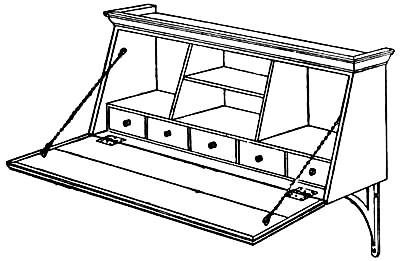

The Writing-desk shown in Fig. 53 is constructed out of a box, and makes a pretty piece of furniture when completed.

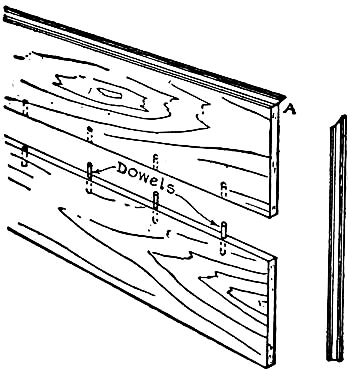

Procure a box as free from defects as possible, and with[Pg 60] fairly wide boards, so there will be but few cracks. The cover should be in not more than two pieces, as it forms the drop-front of the desk, and it would be difficult to fasten more together. The boards must be fastened with "dowels" and cleats on the edges, as shown in Fig. 54, as cleats upon the inside of the drop would be in the way.

Fig. 54.

Dowelling consists in boring holes along the edge of each board and fitting pegs in them. Of course the holes must be bored in exactly the same relative positions in each piece so that the end and sides of the boards will be flush with each other when the pegs have been put in place. To get the holes correctly bored, place the boards together in the vise with two edges flush and uppermost, and square lines six inches apart across the edges, after which locate the centres of the holes on these lines. Be careful to bore the holes straight, and make them a little longer than the pegs. Cut the pegs out of hard wood and make them large enough to fit tightly in the holes.

The pegs as well as the two edges of the boards[Pg 61] should be smeared with glue before being put together. Then, after driving in the dowels, clamp the pieces together and lay them aside until the glue has thoroughly dried. In order to make a neat joint between the two boards, it is very necessary to have the two edges planed perfectly true and square.

While the boards of the drop-front are drying, you can prepare the inside of the box. A boy's desk should be supplied with plenty of pigeon-holes and drawers. They are as necessary as pockets are in his clothes. Split-up cigar-boxes may be used for these divisions, and, by making the upper ones of the right size, cigar-boxes may be fitted in them for drawers. The paper should be removed from the boxes as described in Chapter VIII. Fasten small silk-spools to the front of the drawers for knobs.

When the dowelled pieces have dried, nail a small moulding around the two end edges and one side edge, mitring the ends so as to fit together as shown at A (Fig. 54).

The drop-front should be hinged to the box with two hinges placed on the inside, as shown in Fig. 53, and brass chains attached to screw-eyes screwed into it and the inside of the box.

For the top of the box, purchase a moulding a little larger than that used around the edges of the drop-front and mitre it at the corners, as shown in the illustration.

Before putting any finish upon the desk, sand-paper[Pg 62] the wood, set the nails with a nail-set, and fill all holes and cracks with putty. A couple of coats of white enamel applied to the outside will produce a very pretty effect, and the inside may be finished with linseed oil, which makes a beautiful finish for the cigar-boxes.

The desk should be supported on two iron brackets (enamelled to match the desk), screwed to the wall and under side of the desk.

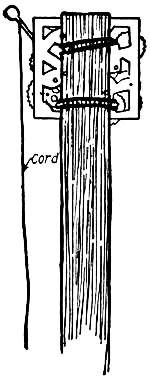

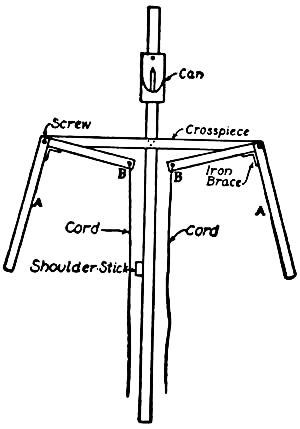

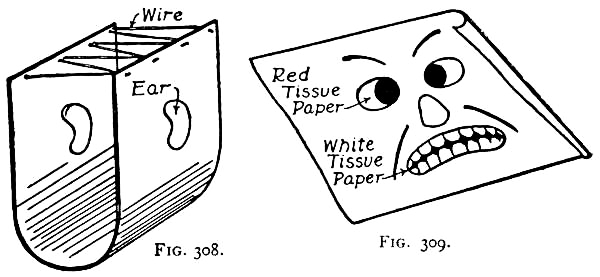

In Fig. 55 will be found