(1) CaSO3 + 2HCl = CaCl2 + SO2 + H2O

(2) Na2SO3 + 2HCl = 2NaCl + SO2 + H2O

The Project Gutenberg EBook of The Puering, Bating & Drenching of Skins, by Joseph Turney Wood This eBook is for the use of anyone anywhere in the United States and most other parts of the world at no cost and with almost no restrictions whatsoever. You may copy it, give it away or re-use it under the terms of the Project Gutenberg License included with this eBook or online at www.gutenberg.org. If you are not located in the United States, you'll have to check the laws of the country where you are located before using this ebook. Title: The Puering, Bating & Drenching of Skins Author: Joseph Turney Wood Release Date: October 26, 2018 [EBook #58168] Language: English Character set encoding: UTF-8 *** START OF THIS PROJECT GUTENBERG EBOOK PUERING, BATING, DRENCHING OF SKINS *** Produced by Thiers Halliwell, Chris Curnow and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

In this e-book a black underline indicates a hyperlink to a page, illustration or footnote (hyperlinks are also highlighted when the mouse pointer hovers over them), and a red dashed underline indicates the presence of a concealed comment which can be viewed by hovering the mouse pointer over the underlined text. Page numbers are shown in the right margin and footnotes are at the end. Footnotes are listed at the end.

The text contains tables, equations and chemical formulae that might not display correctly on small reading devices – a standard web browser is recommended.

The text of the book has mostly been preserved in its original form, including inconsistent italics, capitalisation, and hyphenation. However, some defects have been corrected silently, such as missing/inconsistent punctuation, parentheses and spacing, and an erroneous ÷ has been replaced by − in a fraction in footnote 69. Tables have been formatted to match the originals, but a large table that was originally split over four pages (pp. 98–101), has been condensed into two sections. Some illustrations have been positioned closer to the relevant text and the location may not correspond to that specified in the list of illustrations.

The following typographic corrections have been made:

mutiplied → multiplied

Kothbeize → Kothbeizen

of → on

phenolphtalein → phenolphthalein

hydroxylion → hydroxyl ion

Ca(OH2) → Ca(OH)2

pepsine → pepsin

bibliographic xref (9) → (19)

The following inconsistent spellings have not been altered:

Frankfort a/M – Frankfort o/M

Zenckeri – zenkeri

Casenin – Caseuin

Kentniss – Kenntnis – Kenntniss

resistant – resistent

c.c. – c.cm.

ureaæ – ureæ

ae – æ

The cover image of the book was created by the transcriber and is placed in the public domain.

THE

PUERING, BATING & DRENCHING

OF SKINS

Scientia et potentia humana in idem coincidunt, quia ignoratio causæ destituit effectum. Natura enim non nisi parendo vincitur: et quod in contemplatione instar causæ est, id in operatione instar regulæ est.

Knowledge and human power are synonymous, since the ignorance of the cause frustrates the effect; for nature is only subdued by submission, and that, which in contemplative philosophy corresponds with the cause, in practical science becomes the rule.—Bacon, Aphorism III.

DEDICATED

TO

SIR JOHN TURNEY

THE VETERAN

OF THE

LIGHT LEATHER INDUSTRY

IN

GRATEFUL ACKNOWLEDGMENT

| PAGE | ||

| LIST OF ILLUSTRATIONS | ||

| PREFACE | ||

| I. | DESCRIPTION OF THE PUERING AND BATING PROCESS | |

| II. | THE CHEMISTRY OF BATING | |

| III. | THE PHYSICS OF BATING | |

| IV. | THE BACTERIOLOGY OF THE BATE | |

| V. | ACTION OF ENZYMES | |

| VI. | ORIGINAL PAPERS ON BATING | |

| VII. | ARTIFICIAL BATES | |

| VIII. | PATENTS | |

| IX. | DRENCHING | |

| X. | ORIGINAL PAPERS ON DRENCHING | |

| XI. | BIBLIOGRAPHY | |

| CONCLUSION | ||

| INDEX |

| FIG. | PAGE | |

| 1. | Curve showing removal of lime by washing | |

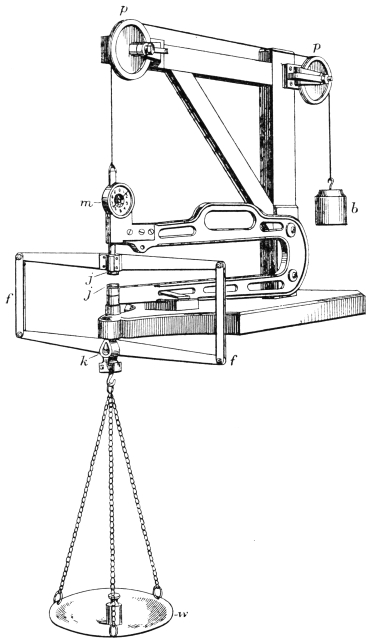

| 2. | Cubical “truck” for measuring skin | facing 8 |

| 3. | Puer wheel | " 13 |

| 4. | Front elevation of puer wheel | |

| 5. | End elevation and section of puer wheel | |

| 6. | Sir John Turney’s scudding machine | facing 17 |

| 7. | Curves of ash contents during puering | |

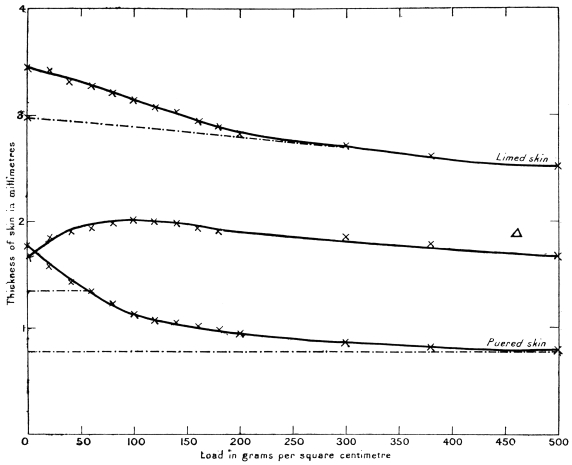

| 8. | Diagram of volumenometer | |

| 9. | " connexions of electrometric apparatus | |

| 10. | Electrometric apparatus | |

| 11. | Apparatus for measuring degree of falling | |

| 12. | Curves obtained by measuring apparatus | |

| 13. | Improved apparatus for measuring degree of falling | |

| 14. | Various forms of bacteria in puer liquors | facing 88 |

| 15. | B. coli commune | " 88 |

| 16. | B. erodiens (Becker) | " 97 |

| 17. | Plate culture from fresh puer | " 97 |

| 18. | " " puer wheel | " 103 |

| 19. | B. putrificus | " 103 |

| 20. | Organisms in pigeon dung, × 1000 | |

| 21. | Pure culture of bacillus (d) from sweated skin | facing 106 |

| 22. | " " " (e) " " | " 106 |

| 23. | B. butyricus (Hueppe) | " 112 |

| 24. | Spirillum volutans (Kutscher), stained to show flagellæ | " 112 |

| 25. | " " " unstained preparation | " 112 |

| 26. | Curves showing rate of hydrolysis | |

| 27. | Organisms in bran drench, × 1000 | |

| 28. | Chains of bran bacteria, × 1000 | |

| 29. | Bran fermentation, advanced stage | |

| 30. | B. furfuris, α | facing 269 |

| 31. | B. furfuris, β | " 269 |

| 32. | Cultures of α in glucose gelatin | |

| 33. | Gas curve (B. furfuris) |

The present volume is the outcome of a desire to preserve the numerous notes which I have made during over twenty years’ work at the practical and scientific study of bating. It has been my wish to complete the investigation of this important process in leather manufacture, for, as Lord Allerton has paradoxically remarked:1 “Good leather is made before the skins go into the tan liquor at all,” but owing to circumstances having drawn me more and more to the commercial side of the business, I have been compelled to abandon this project.

When learning the trade as an apprentice every fault in the leather was attributed to this part of the work, and the troubles and miseries of the “puer shop” first caused me to take up the study of puering. I was determined to know the causes underlying the process. Puering is not only a filthy and disgusting operation, but is prejudicial to health, and in the nature of it is attended by more worry and trouble than all the rest of the processes in leather making put together.

By giving a résumé of the work done up to the present time, I hope to be of assistance to the younger generation of Tanning Chemists, to some of whom is reserved the privilege of carrying on the work.

I think it may now be said, at any rate, that the solution of the problem of constructing an artificial bate on scientific principles, which will replace the present crude methods, is well within sight. The principal obstacles are, on the one hand, the inertia of English manufacturers; on the other hand, the class of labour employed in puering is not of the highest order of intelligence. Innovations in most things are resisted, partly because they necessitate changes in the method of working, and partly because of the innate conservatism of human nature. It is certainly a significant fact that although most of the pioneer work on this subject was done in England, the practical side has been taken up in Germany, and by freely spending money on large trials in the works they have enabled the manufacture of artificial bates to be developed on a commercial scale.

In 1886, while studying Chemistry under Professor Frank Clowes, I began to examine microscopically the various liquors of a light leather factory, and more especially the bran drenches. At that time I knew nothing of bacteriology, for the simple reason that little but pathological work in this line was being done in England. Through the kindness of Professor Clowes, I obtained an introduction to Mr. Adrian Brown (now professor at the University of Birmingham), and in his laboratory at Burton-on-Trent I saw the first pure cultivations of Bacterium Aceti which he had isolated, and of which he had completely studied the chemical action.2 I had there an opportunity of seeing the methods and apparatus employed. I also had the benefit of Mr. Brown’s advice in commencing a systematic study of the process of drenching. Professor Percy Frankland, then at Dundee, advised me further as to the microscope and other matters. My warmest thanks are due to these friends for directing me in the right way.

As a result of my first investigations, on December 11, 1889, I read a short paper entitled “Methods of Bacteriological Research—with some account of Bran Fermentation,” before the Society of Chemical Industry.

The way in which this paper was received led to a further research into the nature of bran fermentation in conjunction with Mr. W. H. Willcox, B.Sc. (now Senior Analyst to the Home Office), by which the action of the bran drench was thoroughly investigated, and the results published in the Journal of the Society of Chemical Industry, May 31, 1893.

This was followed, on June 30, 1897, by a paper “On a Pure Cultivation of a Bacillus Fermenting Bran Infusions,” also in conjunction with Dr. Willcox.

In 1898, in reply to a publication of Director Eitner, of Vienna, I published in the Leather Trades’ Review (November 15), a résumé of the whole subject, entitled “The Rationale of Drenching.”

Already, in the first paper above named (“Methods of Bacteriological Research”), I had called attention to the bacteria of the bate prepared from dogs’ dung, and in a paper entitled “Fermentation in the Leather Industry,”3 developed this aspect of the subject, and first pointed out the influence of enzymes in bating. I therefore decided to study the phenomena occurring in the bate in the same way as I had studied drenching.

The work was begun in 1895, and, as it was likely to occupy an indefinite time, the first instalment, entitled “Notes on the Constitution and Mode of Action of the Dung Bate in Leather Manufacture,” was published November 30, 1898; while “Further Notes on the Action of the Dung Bate” was published on November 30, 1899.

In these papers I indicated the lines on which a culture of bacteria might be practically applied to the bating of skins, and gave the composition of a liquid which, while acting as a nutrient medium for the bacteria, contained at the same time most of the active chemical compounds of dog dung.

Meanwhile, Dr. Popp and Dr. Becker, in Frankfort a/M, were investigating independently the bacteria of dog dung, and conceived the idea of employing them commercially. My dear friend Franz Kathreiner, of Worms,4 put me in communication with these gentlemen, and we were thus enabled to work in conjunction. As a result of our combined labours, an artificial bate, called “Erodin,” was put upon the market. This will be fully treated of in the chapter on Artificial Bates.

I shall give first a short account of bating, and then sum up as briefly as possible the present state of our knowledge of the process, afterwards giving an account of the more important of the various patents which have been taken out for artificial bates.

Although the book is divided into separate sections for convenience, it is obvious that we cannot separate chemistry from physics, nor bacteriology from chemistry, nor enzyme action from all three.

My own papers are printed as read. The Bibliography does not profess to be complete, but includes most of the works consulted.

No one realizes more than I how incomplete the work is, and how much research still remains to be done in order to complete it.

Thanks to the efforts of the Leather Industries Department of the University of Leeds, and the Technical College of the Leather Sellers’ Company, Bermondsey, the era of Rule of Thumb is passing, and there is little doubt that the work that is being done in these institutions will be translated into practical use in the factories by the coming generation.

I wish to express my special thanks to Mr. Douglas J. Law, and to Dr. H. J. S. Sand for assistance in preparing the notes for publication, to Dr. J. Gordon Parker, Director of the Leather Sellers’ Technical College, London, for the description of the bating of hides, and to Professor Kràl, of Prague, for some of the photographs of bacteria.

JOSEPH T. WOOD.

Nottingham : January 1912.

“Beizen sind Stoffe die mit dem Kalk nicht nur ein chemische Verbindung einzugehen im Stande sind, wodurch derselbe löslich und somit vollständig unschädlich wird, sondern auch den gegenseitigen festen Schluss der einzelnen Wandungen der Zellenelemente mechanisch lockern, den ganzen Bau der Haut in sich nachgiebiger machen und so die Verschiebbarkeit der einzelnen Hautgebilde erhöhen.”—J. C. H. Lietzmann, 1862.

“Bates are materials which are not only able to enter into chemical combinations with the lime, whereby it becomes soluble, and is thereby rendered completely harmless, but they also mechanically loosen the cementing substance of the separate cell elements, and render the whole structure of the hide more pliable, and thus increase the mobility of the various parts.”

The object of bating or puering is to render the skins, and the resulting leather, soft and supple. Skins which have undergone the liming process, must be thoroughly freed from lime before going into the tan liquors, and, for light and soft leathers, they must be reduced or “brought down,” so that the elasticity or resilience of the skin fibres is got rid of, and the skin, when tanned, can be stretched without springing back. This is usually done in the case of light leathers, by passing the skins through a bate or puer, composed of an infusion of dogs’ dung in water at a temperature of 35° to 40° C., until the required result is obtained. This condition is known to the workman by the feel of the skin. A good indication is, that the skin when “down” retains the impression of the thumb and finger if squeezed. A properly puered skin, when dropped on the floor, will also be perfectly flaccid, the folds lying closely together. It may, however, be said that it is only by experience and a kind of instinct that the exactly correct condition of the skin can be judged.

I know of no very early works on leather manufacture giving an account of bating. It was a “secret process,” and the results obtained depended almost entirely upon the judgment of the operator; and this judgment was frequently in error, owing to the fact that he did not understand what took place in the bate.

The earliest account I have been able to find is in a book5 in the possession of Mr. Seymour-Jones, of Wrexham, entitled “The Art of Tanning and Currying Leather, with an Account of all the Different Processes made use of in Europe and Asia for Dying Leather Red and Yellow, Collected and Published at the Expense of the Dublin Society, to which are added Mr. Philippo’s Method of Dying the Turkey Leather as approved of by the Society for the Encouragement of Arts, etc., and for which he had a Reward of £100, and their Gold Medal, for the Secret. Also the New Method of Tanning invented by the late David Macbride, M.D., London. Reprinted for J. Nourse, on the Strand, Bookseller to His Majesty, 1780.”

In the chapter entitled “Alumed Calf Skins for Bookbinding” (p. 138), after the limed skins have been fleshed, the writer continues—

“To alum them, put into a large vat, three or four pails of dogs’ turd (this dogs’ turd is called alum); on this they fling a large pail of water to dilute it; this done, the workman goes into the vat, and, with his wooden shoes, tramples it, filling the vat half full of water. The alumer, on his part, pours water out of his boiler into this vat, mixing it with the cold water, after which he flings in the skins, stirring them and turning them for some moments with great sticks.”

The work is described pretty much as now practised, the puer tub being kept at a uniform heat by constantly taking out liquor, heating it, and returning it. But neither these goods, nor morocco, are put through a “drench” after the puer, as we do now; they are scudded on the flesh, and well washed several times in clear water before being tanned.

Morocco Leather (p. 204).—The dry skins are soaked three or four days, “pared” on the beam, and unhaired in weak lime pits one month. At Nicosia they put the skins into lime, reduced to powder, for twenty days in summer, or twenty-five to thirty in winter; out of the lime, the skins are well washed and drained. The author continues—

“The river work finished, the skins are put into the dogs’ confit, or mastering; for every four dozens of skins they add one bucket of dogs’ excrement, containing fourteen or fifteen quarts, which is worked up with their hands into a kind of pap and well diluted. The skins are flung in, stirred and worked in the mastering for some minutes, then turned and left to rest.

“They remain about twelve hours in the mastering, which opens them, and takes off the rawness, disposes them to relax, fill and ferment. This excrement, by its alkaline parts, also cleanses them and takes out the grease, which would hinder them from taking the colour. I shall hereafter speak of bran mastering.

“At Diarbekir, they make use of these masterings in a different way. Whilst the skins are drying, they fill great hollows made in the earth, like our lime pits, with dogs’ dung, which is diluted to the consistence of honey, or of thin pap, in which they soak the skins for eight days in winter, and three in summer, treading them each day with the feet. They are taken out of this fecal matter, and well washed with fresh water, after which another mastering is made with bran diluted with water, in which the skins are soaked six days in winter, and three in summer, observing to tread them each day with the feet, the same as in the dogs’ mastering; they are then taken out, washed in fresh water, and prepared for dyeing.”

From these primitive methods the majority of tanners, even of the present day, have departed but little, except that, instead of stirring the goods and liquor with a stick, a paddle is used, and the process thus shortened considerably. Before describing the operation of puering, it will be best to describe the preliminary washing of the skins, because, although limed skins may be entered direct into the puer and brought down quite satisfactorily, in this case more puer and more time are required, hence it is usual to get rid of the bulk of the lime by washing them in water before putting them into the puer. In some cases very dilute hydrochloric or other acid is used, in order to shorten the time of watering.

It is now well known that lime cannot be entirely removed from skins by washing in water, no matter how long the washing be continued. A limed skin containing 4·6 per cent. CaO, calculated on the dry weight, was found to contain after washing—

Time of washing | Per cent. CaO on dry skin | Per cent. lime removed | |

1 | hour | 3·05 | 34 |

2 | hours | 2·20 | 52 |

3 | " | 1·75 | 62 |

6 | " | 1·55 | 66 |

7 | " | 1·55 | 66 |

24 | " | 1·50 | 67 |

If the washing be continued, a less amount of lime is removed in each successive period of time, so that it is evident a point is soon reached at which it becomes a waste of time to continue the washing. In practice this point is reached in about two hours. The progress of the washing is best shown by the curve in the diagram (Fig. 1), in which the ordinates represent the percentage of lime (CaO) in the dry skin, and the abscissæ time in hours. It will be seen that the character of the curve is a hyperbola; such a curve only approaches a line (representing in the example chosen about 1 12 per cent. of lime) asymptotically—in other words, it is impossible to wash out all the lime except by an infinite number of changes of water, since each washing removes a less amount than the previous one. The above is a typical case of the washing of limed grains from the splitting machine in the manufacture of skivers. These contain from 4 to 5 per cent. of lime on the dry skin, and, after washing in water in a paddle for six hours, analysis shows them to contain still about from 1·5 per cent. to 1·9 per cent. of lime (CaO).6

The effect of washing depends on the character of the water (hard or soft), and also on its temperature. Hard waters should have a small quantity of clean lime added to them before entering the goods, in order to remove dissolved CO2, which, by carbonating the lime on the surface of the skins, renders the grain harsh and the subsequent puering difficult.

With regard to temperature, it is preferable to employ cold water until the bulk of the lime is out, since this dissolves more lime than warm water. 100 c.c. of saturated lime water, at 10° C., contains 0·134 grm. CaO. 100 c.c. at 40° C. contains 0·1119 grm. CaO. Moreover, a comparatively small rise of temperature causes a considerable decomposition in a fully limed skin, by which the skin substance is rendered more soluble, and consequently lost for the purposes of the tanner. For a fully limed skin the limit of temperature is about 82° F. (28° C.), whereas a skin free from lime or alkali may be submitted to a temperature of 120° F. (49° C.) without damage to the fibre. Lamb prefers a short washing of half an hour in water at 35° to 38° C., for the reason that the increased temperature causes the goods to become more flaccid, but this condition is attained at the expense of the loss of skin substance we have mentioned.

In order to save time and water, the following method is adopted. The goods are measured by means of a cubical truck on wheels (Fig. 2); it holds 250 kilos of wet skins (550 lb.). Four of such trucks are placed in a wash wheel, and a stream of water from a 1-in. pipe turned on. The goods are run from three-quarters of an hour to one hour; the water is then stopped, and 4000 c.c. of commercial hydrochloric acid (18° Bé.) is run in slowly, in a very diluted state, through a perforated lead pipe. After all the acid has run in, the wheel is run for half an hour, then water turned on again for half an hour in order to wash away the calcium chloride produced. During this last washing, hot water is admitted at the back of the wheel through a perforated pipe, in order to raise the temperature of the goods, so that they do not enter the puer wheel in a cold condition, and thus lower the temperature of the puer liquor. The goods are now ready for puering.

The chemical action of the acid is a very simple one, and is expressed by the formula—

It will be noted that the quantity of acid used is only about one-tenth of that required to neutralize completely the lime in the skin. If a greater amount of acid be used the skins begin to absorb acid before the lime in the interior is neutralized; but, provided the lime on the surface of the skins is removed, that remaining in the interior is forced out during the course of the bating process (see Chapter III.). If more acid were used, then it would require to be added so slowly that time would be wasted unnecessarily in doing the work.

With regard to the use of other acids for deliming, Lamb considers formic acid preferable to hydrochloric, and states that the removal of lime is more effectively accomplished by its use. He attributes a pulling down action to the calcium formate produced, so that less formic acid is required than would be equivalent to hydrochloric, merely regarded as a solvent for lime. We shall refer to this point again in Chapter II. It may be stated here that the author has obtained better results by the use of a mixture of formic and acetic acid, in equal proportions, than from either acid alone, but that the cost of working is considerably greater than with hydrochloric acid.

Lactic acid is in fairly common use as a deliming agent. In practice 1 per cent. lactic acid (50 per cent. strength) calculated on the wet weight of pelt, is used, added gradually in small quantities. This does not remove the whole of the lime, but sufficient for the skins to puer quickly.

Some tanners measure their acid per dozen skins. In a case which came under my notice, 1200 c.c. 90 per cent. formic acid were being used for ten dozens medium goat skins at a temperature of 35° C., time 1 14 hours.

The following table, due to Professor H. R. Procter,8 gives the cost of dissolving 1 lb. of lime at present approximate prices of the various acids. The dissociation constant K shows their relative “strength;”9 the equivalent, Eq., the weight in lb. of 100 per cent. acid required to dissolve 28 lb. of lime. Ordinary wet limed hides, unhaired and fleshed, contain only about 4 lb. lime per 1000 lb. wet weight.

Cost of Acids to remove 1 lb. Lime.

Acid | Eq. | K | Cost per cwt. | Strength per cent. | Cost for 1 lb. CaO | |

s. | d. | d. | ||||

| Hydrochloric | 36·5 | say 200 | 3 | 3 | 31·5 | 1·4 |

| Sulphuric | 49·0 | " | 4 | 0 | 95·0 | 0·8 |

| Oxalic | 63·0 | 0·1 | 30 | 4 | 99·0 | 8·1 |

| Formic | 46·0 | 0·0214 | 35 | 0 | 87·4 | 7·0 |

| Lactic | 90·0 | 0·0138 | 26 | 0 | 49·7 | 18·0 |

| Acetic | 60·0 | 0·0018 | 18 | 0 | 40·0 | 10·0 |

| Butyric | 88·0 | 0·00115 | 21 | 0 | 82·8 | 8·0 |

| Boracic | 62·0 | 0·00000001 | 27 | 0 | 99·0 | 6·5 |

It will be seen from the above table that sulphuric is the cheapest acid to use; but, owing to the insoluble nature of the calcium sulphate, it is best to use hydrochloric acid. Procter has suggested using a mixture of sulphuric acid and common salt in molecular proportions, so as to avoid the iron which is generally present as an impurity in commercial hydrochloric acid. The author has tried this, and found it perfectly satisfactory. For a complete discussion of chemical deliming, see Procter’s “Principles of Leather Manufacture,” chapter xiii.

Quite recently butyric acid, which is now being manufactured on a commercial scale by the process of Dr. Effront (Brussels), has come into use for deliming.10 and is likely to become a useful acid, as it can be manufactured cheaply. According to Parker, it dissolves less skin substance than formic, acetic or lactic acids, which observation is confirmed by Thuau. The quantity required per 100 lb. of ordinary washed sheep skin is about 12 lb. of the 80 per cent. acid. It is used in exactly the same way as other acids, i.e. it should be added in small quantities, suitably diluted, at successive intervals of time.

Acid salts are also used for deliming, and Procter suggested sodium bisulphate NaHSO4 (“Principles,” p. 155). More recently, sodium bisulphite (NaHSO3) has been recommended;11 the skins are tumbled for half an hour with a dilute solution, which combines with the lime according to the following equation—

if sulphides are present the reaction is—

After this treatment the theoretical quantity of hydrochloric acid, diluted with plenty of water, is run in through the axle of the tumbler, and the skins run another half hour. The reactions are—

(1) CaSO3 + 2HCl = CaCl2 + SO2 + H2O

(2) Na2SO3 + 2HCl = 2NaCl + SO2 + H2O

The sulphurous acid evolved in this way slightly swells the skins, and also removes stains due to the alkaline polysulphides; it is also said to remove salt stains.

| CH2 CH2 | O | |

| CH2 CO |

After washing and deliming, the goods, warmed to a temperature of 90° to 100° F., are now measured in the truck above described, and put as quickly as possible into the bating paddle. This is constructed to carry two trucks. The figures (Figs. 3, 4 and 5) show a modern paddle adapted for puering light skins, such as goat, sheep, splits (grains), either with dung or with an artificial bate.

The inside dimensions are: length, 4 ft. 6 in.; width, 4 ft.; depth, 2 ft. 6 in. A copper pipe of two coils is provided at the back, through which steam is passed for maintaining the temperature of the wheel—the goods are prevented from coming in contact with this pipe by a perforated board. Another steam pipe, jointed so that it may be turned in and out of the paddle, is provided for heating up the wheel to the required temperature before beginning the bating. This pipe is not shown in the drawing. The thermometer can be read while the paddle is in motion. A suitable speed to keep the goods in motion is twenty revolutions per minute. The whole wheel is covered in, for the purpose of preserving the heat, and also to exclude light and air, which are prejudicial to the action of the bacteria. Such a paddle, or wheel, has a capacity of 200 gallons liquor, or 900 litres, and will bate 25 dozens of average grains, weighing in the wet state 1100 lb. or 500 kilos.

The dog dung, which is usually obtained from hunting kennels, and of which the composition is given in Chapter II., is simply diluted with water in the paddle;13 five buckets, weighing about 165 lb., are required for the above quantity of goods.14

The amount used depends on the state of the goods, the prevailing weather, and, further, on the quality of the puer.15 When the temperature is maintained at 40° C., ordinary limed goods, which have been washed, come down in from one to three hours.16

During puering, the lime soaps in the skin are decomposed, and the fat set free—in an estimation of the fat, 0·151 per cent. on the wet skin was found before puering, and 2·48 per cent. after puering. The fat thus set free can be removed to a great extent by scudding; but in modern practice this is not pushed to extremes, as the grain is liable to be damaged by excessive scudding. The fat is afterwards removed from the dry leather by means of benzine or other solvent, employed in a suitable apparatus.

Scudding.—When the goods are “down,” they are ready for scudding. This operation in the case of grains is performed either by hand over the beam, or by means of a special scudding machine.

The scudding machine figured (Fig. 6) was invented by Sir John Turney in 1880,17 and is the only type of machine which will safely scud split skins. It will readily be understood that the usual type of scudding machine, in which a spiral knife is used, would tear the delicate structure of the grain. The Turney scudding machine works with hard, circular brushes, which revolve against a wooden roller carrying the skin. At the same time a continuous stream of water, at a temperature of 110° F., is sprayed upon the skins from a perforated pipe.

After scudding, the skins are washed in cold water for about ten minutes. This checks the action of the puer, and also washes away any loose dirt. They are then ready to pass on to the drench (Chapter IX.), or to the pickling process, or direct to the tan liquor, according to the kind of leather required.

The Bating of Hides for Harness or Dressing Purposes.—The hides intended for harness leather, or for dressing purposes, are usually bated with hen or pigeon manure. The exact process varies in different tanyards, being dependent upon the condition of the pelt prior to bating, as to whether it is bated directly after fleshing or receives a preliminary deliming. The process is also dependent upon the amount of bating action required for the specific purpose prior to tanning, but the following three methods are in actual use, and may be taken as typical methods:—

Harness Backs.—About a hundredweight of hen manure is put into a suitable tub or vat capable of holding about fifty gallons; some thirty gallons of water, at a temperature of about 100° F., is poured on to the manure, and the whole is thoroughly stirred up by means of a wooden stick or plunger, working the manure about in order to mix it to a consistence of thin soup. The vat is now stored in a warm place, so that the temperature is kept about 70° F.—it is customary to store this in the boiler-house, or some similar warm room. It should be stirred two or three times a day, until it begins to show signs of working; two days is generally sufficient for this.

A pit is now prepared, with the necessary amount of water; and, by the aid of a steam pipe, or other similar means, the temperature of the water is raised to 70°, and the contents of the bate tub are now added. This should be poured into the pit through a sack, or a canvas filter, so as to keep back stones, solids, feathers, and other extraneous matters. The pit is now thoroughly plunged, and the goods entered; these should be handled up three to four times a day for two days. At the end of two days the goods are usually scudded, by working the back on an ordinary unhairing beam with an unhairing knife. They then go into a fresh pit containing a new solution of bate made up in the same manner, and, when sufficiently bated, which generally takes about three days, the goods are removed from the pit, scudded again by working them over with a slate scudding tool, when they are ready for tanning. Some tanners give them a bath of boracic acid prior to their going into the tanning liquor; this has the effect of materially brightening the colour. The second pack of harness backs go into the same liquor—which must be re-warmed to a temperature of 70°—in which they are handled as before for about two days, and are finished off in a new liquor made as above described.

It will be understood, therefore, that in a tanyard, working regularly, the pack of backs go first into an old bate for two days, and are then finished off in a freshly made one; so that each pack gets two days in an old pit, and one or more days in the new. The bate in the tub may also have a second water, or be strengthened.

Dressing Hides.—For these goods a somewhat stronger bating effect is required, and pigeon manure is therefore frequently used. The preparation of the bating liquor is as described above, both as regards quantity and temperature of the water and time of maceration.

The whole process may be carried out exactly as described for harness backs, but the following is an illustration of another method in practical use. Imagine four ordinary bating pits, worked in a round. The first pit is very old, having had three packs of hides through it; the second having had two packs, and the third one pack; and the fourth is made new. The goods, after unhairing and fleshing, and washing, are put into the first pit quite cold, are handled in this three times on the first day, and afterwards put into the second pit, the temperature of the second pit having been previously raised to 65°—the cold pelt going into this pit reduces the temperature to about 60°. They are handled in this pit twice, and remain overnight; and the third day they go into the third pit, the temperature of which is raised to 70° before the goods go in. They are raised, scudded thoroughly on the grain, and new liquor is made from new bating liquor prepared as described above; the goods are now entered, handled at least twice a day, and, if insufficiently bated, are left overnight. By the next day they will probably be sufficiently “down” to permit of them going on to the scudding beam and thence on to tanning.

In the event of any hide being insufficiently bated—in other words, if the “bone” has not completely disappeared in the inner part of the hide—they are returned once more for three or four hours, the temperature of the pit being raised to 70° with a steam coil.

By this system, which is known as a system of “sets,” it will be noticed that the pits are worked in a round of four; the first pit, or oldest, being used more or less as a wash pit, the actual bating taking place in the second, third and fourth pits. No pit has more than four packs passing through it, and the temperature never rises above 70°, or, at the outside, 75°. The reason of the comparatively low temperature is due to the fact that in pit bating, if the temperature is raised above 75°, the grain of the hide becomes affected before the internal “bone” is sufficiently soft, which results in a tender grain, which considerably affects the resulting staining or dyeing which the leather usually receives before it is put on the market.

The Third Process.—This process is suitable for either harness or dressing hides, and differs from the above-described process only in the fact that instead of bating the hides in pits, a latticed drum is used in order to keep the hides in constant motion. This consists of a large pit, in which a latticed drum revolves two-thirds immersed in the liquor. The bate liquor is made up as usual, and the temperature of the liquor raised to 75° or 80° F.; the hides are then placed in the latticed drum, which revolves at from four to six revolutions per minute, and, if the goods are put in the drum in the morning, and if the temperature is kept at about 70° F., the hides are generally sufficiently bated by evening. They may then be taken out of the drum, scudded, and left suspended in boracic acid overnight, and can then be taken to the liquor next morning.

Where there is considerable motion, even the heaviest hides will stand a temperature of 75°, and even 80°. Some tanners who use the latticed drum method, do not place their hides in the drum until the afternoon; they are drummed for about an hour in the cold bate, and left overnight; next morning the temperature of the bate is raised to 75°, and the drum started; they are then removed from the drum towards the afternoon, when sufficiently “down” to admit of them passing forward into the next process.

The above are three typical methods in common use in England, but many modifications of these processes exist. Everything depends upon the amount of lime in the hide, on the number of haulings or handlings given to the goods, and the temperature or the conditions under which the hides are bated, so that no hard-and-fast lines can be laid down. Much also depends upon the method of liming used, prior to the bating. It must be borne in mind that the bating of hides, and even of kips, differs materially from the bating of goat and sheep skins, as one has to deal with double or even treble the substance. If the bate is worked at a temperature of even 70° or 75°, there is the danger of the grain being seriously affected before the bate has penetrated to the interior of the pelt, unless the goods are kept in constant motion.

Instead of a latticed drum, large paddles are used in some factories. If the pit is large enough the paddle causes both hides and liquor to revolve, and thus gives the required movement necessary for a regular and even “bating effect” to be obtained.

“And now, as we cannot understand the frame of a Watch, without taking it into pieces; so neither can Nature be well known, without a resolution of it into its beginnings, which certainly may be best of all done by Chymical Methods”—Jos. Glanvill, 1668.

Professor H. R. Procter, in his “Principles of Leather Manufacture,” 1903, p. 153, has given a very complete account of chemical deliming, and also of the bating and puering processes. Meunier and Vaney, “La Tannerie,” 1903, give a general review of our knowledge of these processes up to that date. These accounts are extremely useful, but treat the subject in a general manner.

I propose to treat of the particular case of puering by means of an infusion of dogs’ dung in water, as I believe this will give an insight into all the other bating processes.

So far as the purely chemical action of the bate goes, it consists in the solution of the lime contained in the skins,18 thus setting free a certain portion of skin substance which was combined with the lime, and the subsequent solution of more or less of this skin substance.

If a fresh puer be made and boiled for half an hour, then allowed to cool to 95° F., it will be found to remove the lime from the skin in a very similar way to an ordinary bate, but it has not so rapid a reducing action as an unboiled bate. In this case both bacteria and enzymes are destroyed, so that the action may be put down to the chemical constituents of the bate.

Chemical Composition of the Puer.—The mineral constituents of the fæces, both in dogs and human beings, are well known, owing to the study of the processes of digestion and nutrition in physiological laboratories; but the organic constituents are yet little known, and the sum of the weight of those at present estimated is far from the total of these matters present.

It is a mistake to suppose that the fæces represent the residue only of the food taken. Strassburger19 estimates that bacteria alone account for nearly one-third of the dry matter. In addition, the intestinal mucous membrane is an important excretory channel for lime, magnesia, iron and phosphoric acid, as has been shown by analyses of fæces from men and dogs, during prolonged fasting.20 Even when no nitrogenous food is eaten, the dry fæces always contain from 4 to 8 per cent. of nitrogen; in a dog fed on meat it amounts to 6·5 per cent.

In making a chemical analysis of the fæces, the mineral matter is estimated in the ash in the usual way for ash of organic substances, with special precaution, on account of the phosphates present. The material is first charred, the salts removed by acetic acid; the acetic acid solution is then decanted, the residue washed with distilled water, and the combustion then completed. The acetic solution and washings are added to the final ash, the whole evaporated to dryness, and gently ignited to decompose the acetates. (Cf. Bull. 46, U.S. Dept. of Agriculture, Washington, 1899.)

In estimating the fats, the dry puer is ground up with sand, then extracted with ether in a Soxhlet. The fats are present in four states:—1, neutral fats; 2, free fatty acids; 3, alkali soaps, soluble in ether; 4, small quantities of lime and magnesia soaps remaining in the residue in the Soxhlet. For details as to the separation and estimation of these, Lewkowitsch’s “Oils, Fats and Waxes” (Macmillan) should be consulted.

The separation and estimation of the organic constituents in the puer, is one of the most difficult problems of physiological chemistry, and to include the methods used would demand a special treatise beyond the scope of the present volume. Hoppe-Seyler’s “Physiological Chemistry,” and Allen’s “Commercial Organic Analysis,” vol. iv., may be consulted; and there is a mass of useful information in Dr. René Gaultiers’ “Précis de Coprologie Clinique” (Paris, Baillière et Fils, 1907).

It is proposed to give here the results of a number of analyses of dog dung made by the author and others, and to discuss the action of the various bodies upon the skins. Many more experiments and much research requires to be done, before the complete action of the bate is clear, but only by the method of experiment with the various bodies present can the problem eventually be solved.

Analysis of raw puer from hunting kennels (Quorn) showed the approximate composition of 1000 grm. of raw puer, containing 150 grm.21 of dry matter to be as follows:—

| Grammes | ||

| Sodium chloride and sodium sulphate | 2 | ·1 |

| Sodium ammonium phosphate | 14 | ·0 |

| Earthy phosphates, principally Ca3(PO4)2 | 33 | ·6 |

| Ferric phosphate | 0 | ·87 |

| Calcium sulphate | 1 | ·94 |

| Silicic acid | 3 | ·40 |

| Calcium in solution as CaO | 1 | ·42 |

| Total P2O5 in solution | 4 | ·00 |

| Non-volatile acids (as lactic) | 3 | ·00 |

| Volatile acids (as acetic) | 2 | ·20 |

| Amines (as ammonia) | 6 | ·20 |

| Enzymes | 3 | ·66 |

| Nitrogenous bodies not included in the above, consisting of complex amido-acids, leucin, tyrosin, xanthin, and other purine bases, indol and skatol | 17 | ·00 |

| Organic matter, cellulose, etc. mostly insoluble, including fats and soaps | 70 | ·00 |

On the dry matter the amounts extracted by various solvents were:—

Per cent. | ||

| Water | 24 | ·03 |

| Alcohol | 22 | ·27 |

| CS2 | 15 | ·57 |

| C2HCl3 (Tri-chlorethylene) | 14 | ·45 |

| Petrol. ether | 13 | ·23 |

No carbohydrates (sugars) capable of reducing Fehling’s solution were found in the puers examined.

The ash22 of the dry fæces from dogs fed on a flesh diet varies from 20 to 34·27 per cent., with the following percentage composition:—

| Silica | 7 | ·04 |

| CO2 | 4 | ·62 |

| SO3 | 7 | ·37 |

| Fe2O3 | 4 | ·22 |

| CaO | 25 | ·29 |

| P2O5 | 26 | ·41 |

| MgO | 15 | ·52 |

| Cl | 1 | ·50 |

| Alkali | 5 | ·53 |

In a dog weighing 30 kilos., fed on a mixed diet of 500 grm. meat and 200 grm. starch, 78·6 grm. dry fæces were obtained containing 23·76 per cent. ash of the following percentage composition:—

| CaO | 22 | ·3 |

| P2O5 | 25 | ·4 |

| Fe2O3 | 10 | ·6 |

| MgO | 9 | ·8 |

| SO3 | 5 | ·0 |

| Cl | 0 | ·2 |

| Alkali | 1 | ·1 |

| Insol. in HCl | 21 | ·8 |

It is obvious that the composition of the fæces will vary with the food given, and in this connexion it may be stated that the puer used was obtained from dogs fed on a mixture of boiled horseflesh and oatmeal porridge, about equal quantities. Sometimes charcoal and cabbage are mixed with the food, in this case the puer is very dark coloured. The dark colour so produced is to be carefully distinguished from the dark colour caused by decomposition of the puer.

We cannot leave out of account the urinary products, which, in the case of dung from hunting kennels, are always present, though in varying quantities.

The total nitrogen in 1520 c.c. of urine was found23 to be 15·9 grm.

Each 100 grm. total nitrogen was distributed as follows:—

| Urea | 85 | ·9 |

| NH3 | 4 | ·1 |

| Creatinine | 3 | ·3 |

| Uric acid | 0 | ·5 |

| N in other compounds | 5 | ·7 |

The inorganic compounds were:—

Per cent. | ||

| Sulphur (as sulphate) | 3 | ·31 |

| P2O5 | 3 | ·98 |

| Cl | 6 | ·30 |

The urine of carnivora is acid, that of herbivora is neutral or alkaline.

Urea, which is the chief nitrogenous constituent, is very quickly fermented by several species of bacteria, and entirely decomposed into ammonium carbonate, so that it is this latter body which acts in the bate.

| CH2 | NHC, H5O | ||

| COOH |

The analysis of the lion’s dung gave the following results:—

Per cent. | ||

| Water | 59 | ·2 |

| Ash | 21 | ·1 |

| Lime (CaO) | 10 | ·3 |

| Phosphates (P2O5) | 10 | ·67 |

| Organic matter | 19 | ·7 |

Dog dung contains some non-volatile bases of the purine group, such as xanthin (C5H4N4O2) and guanin (C5H5N5O), but the action of these bodies in the bate, has not been studied. It is also extremely probable that these and similar bodies are formed during the bating by a process of auto-digestion of various proteids.24 The quantity of fat in dry puer, amounts to 10–11 per cent. Cholesterol was present.25 Part of the fat is in the form of lime and magnesia soaps, but part in the form of an emulsion, which probably plays an important part in the puering process. The function of the fatty constituents of puer is one of the problems on which further research is necessary.

The colouring matters of the puer are nearly all derived from bile products. Most of them are found in the petroleum extract, which contains far more of the colouring matters than the chloroform extract.

The following bile colouring matters have been prepared by Merck, of Darmstadt: bilihumin, biliprasin, bilirubin, bilifuscin, biliverdin.26 So far as has been ascertained by the author, their effect in the bating is nil, but, in so far as they impart colour to the pelt, they are detrimental.

Experiments on the action of bile are given in the paper reprinted in Chapter VI.

Recently Eberle27 has proposed to add a proportion of gall juice (bile) to a bate containing pancreatic enzymes, with a view of energizing the latter. This part of the subject will be dealt with in Chapter V.

The Reactions of the Puer.—The organic acids are present principally in the form of the sodium or calcium salts. The intestinal juices contain sodium carbonate, but this is neutralized by lactic acid found in the intestines, so that the excreta usually have an acid reaction. The reaction of a fresh puer liquor is faintly acid to litmus, but this acid is immediately neutralized by the introduction of the skins, so that the rest of the bating process takes place in a neutral or alkaline medium, and the quantity of lime removed by the free acids is probably small.

The acidity of a filtered puer liquor made up freshly and titrated with N/5 soda, and phenolphthalein as indicator, was found to equal 10 c.c. N/1 acid per 1000 c.c. of bate. In the volume of liquor used, namely, 900 litres, this would neutralize only 250 grm. of lime (CaO).

The determination of the exact acidity or alkalinity of puer liquors by ordinary methods with indicators is not easy, as the end reactions are not sharp. The liquor above described was alkaline to methylorange and litmus, although acid to phenolphthalein, and the results also vary somewhat, according to the quantity of bate used for titration, and according to the strength of the acid or alkali used. The method used, both at the Trent Bridge laboratory and Messrs. Doerr and Reinhart’s laboratory at Worms, is as follows:—

The puer liquor is filtered through a Schleicher and Schulls hard filter, No. 602, 18 12 cm. diam.; 50 c.c. are taken, 4 drops of phenolphthalein solution (10 gr. dissolved in 300 c.c. alcohol) added, and titrated with N/5 acid or alkali as the case may be.

If the acidity be determined by adding excess of alkali and titrating back, a larger amount of acid is found than by direct titration. In the above-mentioned case, an indirect titration showed an acidity equal to 18 c.c. N/10 acid per 100 c.c. of liquor.

On adding the alkali to a fresh filtered puer liquor, a flocculent precipitate is produced, which appears to be due to the decomposition of proteid compounds of weak organic acids,28 the alkali uniting with them and setting the proteids free. As these compounds are undoubtedly decomposed by the lime in the skins, it seems probable that the acidity available for neutralizing lime may be greater than that shown by direct titration.

A method which was suggested by me for the estimation of the acidity of tan liquors may be applied also to the examination of the bate liquors, namely, the method by which the electric potential between a hydrogen electrode dipping into the bate liquor, and a standard calomel electrode, is used to determine the neutral point (for details see Chapter III.), using the potentiometer devised by Dr. H. J. S. Sand.29

Puer liquors, titrated in this manner with N/10 soda or HCl until a potential of 0·69 volts is reached (at which point phenolphthalein turns from colourless to red), gave the following results per 100 c.c. filtered liquor.

| No. | Description of Liquor | Reaction | c.c. N/10 | Alkali | Required for Neutralization | ||

| or | |||||||

| Acid | |||||||

1 | New puer before goods | Acid | 7 | ·4 alkali | |||

2 | The same after goods | Alkaline | 0 | ·57 acid | |||

3 | New puer before goods | Acid | 8 | ·1 alkali | |||

4 | The same after goods | Alkaline | 3 | ·25 acid | |||

5 | Used puer after goods | Alkaline | 5 | ·00 acid | |||

6 | Spent puer | Alkaline | 6 | ·6 acid | |||

Determinations made in this way are more accurate than the colorimetric method above described. Puer liquors after use are found by the electrometric method generally on the alkaline side, whereas such liquors show neutral to phenolphthalein owing to some action of the bate constituents on the indicator.

Puer Liquors in Electrometric Apparatus.

No. | P.D. Before Skins volt | c.c. of N/10 KOH required for 50 c.c. liquor to 0·69 volt | P.D. After Skins volt | c.c. of N/10 HCl required for 50 c.c. liquor to 0·69 volt | Description of Liquor | |||||

A1 | 0 | ·622 | 1 | ·95 | .. | .. | New puer | |||

A2 | .. | .. | 0 | ·747 | 1 | ·9 | A1 after 2 packs skins | |||

B1 | ·607 | 3 | ·7 | .. | .. | New puer | ||||

B2 | .. | .. | ·770 | 3 | ·1 | B1 after 3 packs skins | ||||

C1 | ·580 | 4 | ·3 | .. | .. | New puer | ||||

C2 | .. | .. | ·762 | 2 | ·8 | C1 after 2 packs skins | ||||

D1 | ·580 | 5 | ·2 | .. | .. | New puer | ||||

D2 | .. | 0 | ·8 | ·680 | .. | D1 after 1 pack skins (still on the acid side of 0·69) | ||||

E1 | ·570 | 6 | ·2 | .. | .. | D2 + 4 buckets more puer | ||||

E2 | .. | .. | ·720 | 0 | ·8 | E1 after 1 pack skins | ||||

F1 | ·610 | 3 | ·0 | .. | .. | New puer | ||||

F2 | .. | 0 | ·5 | ·680 | .. | F1 after 1 pack skins (still on the acid side of 0·69) | ||||

The potential at the neutral point, using an auxiliary electrode filled with N/1 potassium chloride, was 0·69 volts. Potentials below this point, therefore, indicate an acid reaction, and, conversely, potentials above 0·69 volts indicate an alkaline reaction. The apparatus is thus very useful in following the course of the bating process. The initial potential also enables the hydrion concentration of the bate liquor to be determined directly (see Chapter III.). It was found that during the bating of a pack of skins the hydrion concentration of the liquor diminished from 10-5·2 to 10-7·4 normal.

Such acidities as are found by this method, e.g. 7–8 c.c. N/10 acid per 100 c.c., are too great if made up by taking a solution of the free acids. The ionization must be almost entirely repressed by the presence of sufficient neutral salts of the same acids in the bating liquid, in order to obtain a similar result to the puer.

The table opposite gives the values found for a series of puer liquors, made with dog manure from hunting-kennels.

The reaction of puer liquors (expressed in c.c. of N/1 alkali or acid per 1000 c.c. of bate), in a series in which the washed goods were run for one hour in old puer, out of which goods had been taken, and then transferred to a freshly-made puer, was as follows:—

Bate | Before Goods | After Goods |

| Old puer | Neutral | 28 c.c. acid |

| Fresh | 10 c.c. alkali | Neutral |

| Old puer | Neutral | 40 c.c. acid |

| Fresh | 11 c.c. alkali | Neutral |

These figures were obtained by the ordinary colorimetric method described on p. 32.

Adding together the alkalinity of the bate run away, and the acidity of the new bate which is neutralized, the total for 1 and 2 = 38 c.c. N/1 acid, and for 3 and 4, 51 c.c. N/1 acid.

Multiplying by 810 (volume of bate less volume of dry skin), we find that the skins have neutralized 30·78 and 41·31 litres N/1 acid respectively. Since one litre of N/1 acid will neutralize 28 grm. of lime, it follows that the lime removed by the bate was in one case 862 grm., in the other case 1157 grm.

The 500 kilos, of wet washed grains introduced into the paddle contain approximately 0·5 per cent. of lime CaO, equivalent to 2500 grm. altogether. As will be seen from the figures given in table, p. 35, the free acids present in the fresh bate are only capable of neutralizing 10 × 810 c.c. of normal alkali, and this is equivalent to 225 grm. of CaO, or 9 per cent. of the total lime.30

In addition to this, a considerable amount of lime is removed from the skins which is not found afterwards in solution, but which is precipitated in an insoluble form during the course of the bating process. In an experiment to determine the amount of this insoluble lime, the following figures were obtained:—

Lime in Puer Liquor, Grams per Litre CaO.

| Before Skins | After Skins | |

| Soluble lime | 0·19 | 0·485 |

| Insoluble lime | 0·13 | 0·485 |

| ─── | ──── | |

| 0·32 | 0·970 |

It will be noted that the amount of insoluble lime has increased to a greater extent than the soluble lime, showing that part of the lime from the skins has been precipitated in an insoluble form. The increase of lime in the solution is 0·295 grm. per litre of soluble lime, and 0·355 grm. per litre of insoluble lime, a total increase of 0·650 grm.; that is, the ratio of soluble lime to insoluble lime in the original puer is 1·46 : 1. In the used puer it is 1 : 1, so that in the above case more than half the lime removed from the skins (54·5 per cent.) has been precipitated in an insoluble form, some of it in the form of calcium phosphate, and the remainder probably in the form of calcium oxalate. Crystals of calcium oxalate may be seen under the microscope in the puer residues.

The oxalic acid is produced by bacterial action, as has been shown by Zopf31 and Banning32; but it is difficult to estimate it in the bate, and a reliable analytical method of doing so requires devising.

A further 30 per cent. to 40 per cent. of the lime in the skins is removed by the chemical action of the complex amines of the organic acids, and by the mechanical effect of the paddle or drum, so that the final result is more or less as follows:—

Per cent. | |

| Lime neutralized by free acids | 9 |

| Lime dissolved by complex amines | 25 |

| Lime precipitated | 30 |

| Lime remaining in the skins | 36 |

── | |

100 |

The lime remaining in the skins is not in the caustic state, but principally in the form of neutral salts (see footnote to p. 24).

Some of these neutral salts appear to be absorbed by the skin during the course of the bating, for, on examining pieces of the same skin at frequent intervals during the operation, and determining the ash, it was found that a minimum point for ash content was reached in about ten minutes, after which the ash actually increased. The results are shown in the following table, and also graphically by the curves, Fig. 7—in which A is a “grain” previously washed as free from lime as possible; B, an unwashed “roan.” The effect of the absorption of inorganic matter is very noticeable in both cases. A part of the effect only is apparent since a certain amount of skin substance passed into solution.

Variation of Ash Percentage during Puering.

— | Ash, per cent. on Dried Skin | |

Time of Puering in Minutes | Washed Delimed Grain (A) | Limed Roan (B) |

0 | 2·88 | 7·03 |

5 | 2·91 | — |

10 | 3·20 | 3·54 |

15 | 4·80 | — |

20 | 4·08 | 4·24 |

25 | 4·29 | — |

30 | 4·85 | 5·19 |

35 | 4·59 | — |

40 | 4·70 | 5·45 |

45 | 4·60 | — |

50 | 4·45 | 5·67 |

55 | 4·42 | — |

60 | — | 5·00 |

The following analyses give the amount of lime in solution before and after the bating of the skins, in grams per litre of filtered puer liquor:—

No. | Bate | Before Goods | After Goods | Increase of CaO |

1 | Fresh puer | 0·108 | 0·62 | 0·512 |

2 | " " | 0·34 | 0·72 | 0·38 |

3 | " " | 0·20 | 0·52 | 0·32 |

4 | " " | 0·19 | 0·49 | 0·30 |

5 | Old puer | 0·54 | 0·84 | 0·30 |

| 6 | Old puer, goods not washed. | 0·98 | 1·38 | 0·40 |

| 7 | French puer shop. | 0·308 | 0·548 | 0·24 |

The limit of the quantity of lime in solution in a normal puer, in the form of calcium salts, appears to be about 1 grm. per litre. If more lime be presented to the liquor, the goods stop coming down. If now fresh dung be added, they will continue to come down, but the quantity of lime in solution does not increase; the excess of lime is precipitated, partly as phosphate and partly as oxalate, in the way stated above.

The type of reaction by which the lime is dissolved is similar to that occurring between ammonium chloride and lime, and is expressed by the formula—

and in the case of the calcium carbonate in the skins—

so that every molecule of lime neutralized, liberates two molecules of ammonia.

Jean states that the production of ammonia progresses regularly during the puering, and that when the free ammonia reaches 0·2 grm. per litre the bate is unfit for further use. But if the excess of ammonia be neutralized by the addition of phosphoric acid, which also precipitates the lime brought in by the skins, the bate may be kept in constant use for some time. Jean found 0·06 grm. NH3 per litre in the puer as made up for use, and, after one lot of skins had been put through, 0·086 grm. per litre; after two lots of skins, 0·135 grm. per litre. In ordinary puer wheels, as used at Trent Bridge, we find—

(a) | (b) | |

| Before goods | 0·0816 | 0·0850 grm. NH3 per litre |

| After " | 0·0833 | 0·0799 |

so that there is little or no difference before and after puering in this case.

Part of the ammonia formed escapes into the air; a further portion unites with the acids which are being formed by the action of bacteria in the bate (see Chapter IV.), and it is also probable that part combines in some way with the calcium salts in the bate.

The actual reactions taking place are of course much more complicated than this simple case, because, instead of ammonia and ammonium chloride, we have a number of complex salts formed by combination of organic acids with substituted ammonia derivatives, such as methylamine, ethylamine, etc. The chief of these are ethylamine and methylamine butyrates, and lactates, and probably propionates, although I have not been able to separate the latter.33

The reaction with the butyrate is represented by the equation—

2C2H5NH2C3H7COOH + CaO

| = 2C2H5NH2 + | C3H7COO | Ca + H2O | |

| C3H7COO |

by which it will be seen that the amine is set free just in the same way as ammonia in the equation on p. 40.

In order to ascertain if the action of the amines was the same as that of salts of ammonia, I prepared the following compounds and tested their action on skins at 37° C., a control piece of the same skin being kept in water at the same temperature. The time in each case was one hour. All the solutions were neutral.

1. Ethylamine lactate: skin swells slightly, not “down” equal to puer.

2. Ethylamine propionate: skin moderately fallen, not equal to puer.

3. Ethylamine butyrate: about the same as Exp. 1.

4. Trimethylamine butyrate: very similar action to Exp. 3 and to ammonium butyrate.

The results correspond very closely with those obtained in previous experiments with various salts of ammonia (see Chapter VI.), and justify us in assuming that in all essential respects the action is similar. The free amines enter into fresh combinations with acids which are produced by bacterial action, and this process goes on until all the nutrient material is exhausted.

The Role of Phosphates in the Bate.—There is no doubt that the phosphates in the bate play an important part, but exactly in what manner they act is not yet known. One of the principal effects is the part they play as “buffers,” in preventing brusque changes of the hydrion concentration during the bating process. This has been pointed out by Soerensen in the case of enzyme reactions. The phosphates in dung are mixtures, which are capable of fixing both acids and bases; and so the small quantities of these bodies, which are produced by the splitting up of the organic matter, are taken up or released as the case may be.

The chemistry of the phosphates is one of the most complicated branches of inorganic chemistry, and, as a consequence, the determination of the constitution of the various phosphates in dung is an extremely difficult matter, and demands a lengthy research. For instance, besides the salts directly derived from the three phosphoric acids, HPO3, H3PO4 and H4P2O7, phosphates exist which are probably derived from hypothetical di-, tri-, or meta-phosphoric acid, nHPO3, and a few salts have been isolated, which are perhaps derived from the hypothetical acids P4O7(OH)6 and P10O19(OH)12 (Watt’s Dict., art. “Phosphates”). Including the double salts, there are more than 16 different calcium salts of phosphoric acids. The normal lime salt Ca3(PO4)2 is very slightly soluble in water, but its solubility is increased by the presence of various organic substances such as exist in dung, and part of the soluble phosphates found in the bate are undoubtedly nothing more than this salt in solution. This fact has been utilized in the manufacture of the artificial bate Erodin (see Chapter VII.).

The phosphoric acid in the puer is partly precipitated by the lime in the skins, and hence diminishes during the bating process. In some cases practically the whole of the phosphoric acid disappears from the solution.

The following experiment will give an idea of the amount of lime precipitated as phosphate. A filtered puer liquor was analysed for lime and phosphoric acid, before and after the skins were passed through. The results were, in grm. per litre—

| Before | After | |

| Soluble lime as CaO | 0·364 | 0·540 |

| P2O5 | 0·424 | 0·328 |

Increase of lime, 0·176 grm.; diminution of P2O5, 0·096 grm. Calculated to calcium phosphate Ca3(PO4)2, this amount of phosphoric acid has combined with 0·114 grm. CaO. Assuming that the ratio of soluble to insoluble lime is the same as given, p. 36, then the lime is distributed as follows:—

| Grm. | ||

| Increase of soluble CaO | 0·176 | |

| " " insol. CaO | 0·210 | |

| Lime as Ca3(PO4)2 | 0·114 | |

| Hence | " " oxalate (?) | 0·096 |

That is, of the lime precipitated, 54 per cent. is phosphate, 46 per cent. oxalate.

In another puer containing before use 0·383 grm. P2O5 per litre, only traces of phosphates were found in solution after goods had been puered in the liquor, and in some analyses by Jean (39) the following figures were obtained:—

Grams of Phosphoric Acid per Litre.

| Fresh dung after four days’ maceration | 0·082 |

| Bate after one pack of skins | 0·036 |

| Bate after two packs of skins | 0·018 |

Although these figures are less than those found at Trent Bridge, they confirm the fact that the soluble phosphates diminish during the bating process.

The phosphates in solution thus diminish during the bating, and are found in the insoluble matter which separates out. A small portion of the lime remaining in the skins is also converted into phosphate by the action of the bate. In an experiment to determine this, a portion of the same skin was taken before and after puering. The pieces were dried, ashed, the ash dissolved in dilute nitric acid, and the phosphates precipitated by ammonium molybdate. In the skin before puering no phosphates were present, but in the skin after puering there was a small amount, though not sufficient to weigh.

The action of ammonium phosphate on the lime in the skin is very small. A skin was treated with a 0·1 per cent. solution of ammonium phosphate at 100° F. for one hour. The CaO in the dry skin was estimated, and found to be—

Per cent. | |

| Before the experiment | 1·93 |

| After " " | 1·45 |

A considerable amount of calcium phosphate was found in the skin after the experiment.

Other chemical compounds existing in the puer, or formed by the action of bacteria (principally B. coli commune, see Chapter IV.), are indol, skatol and a number of aromatic oxyacids, principally para-oxyphenyl-propionic acid, a little para-oxyphenylacetic acid and skatol carbonic acid. In addition, tyrosin, leucin, tryptophan and mercaptans have been separated.34

With these bodies no experiments on skin have been made, so far as I am aware, except with indol and skatol. Kathreiner found that these had a slight reducing action on skin, so that one may say they play some part in the puering.

The action of the bile salts, glycocholate and taurocholate of soda, also needs investigation. These have an indirect effect in the puer, as they favour the development of some species of bacteria (chiefly coli) and hinder the growth of others.

Some action has also been ascribed to sulphuretted hydrogen, but in the puer liquors which I have examined no H2S was found, either before or after the skins were entered.

It will be seen that the ammonia compounds in the bate are not of themselves particularly fitted for the purpose of removing lime35 from the skins, but owing to bacterial action (which we shall treat of in Chapter IV.), acids are produced which combine with the ammonia, and in this way the small quantity of these compounds originally present is continually being regenerated while the bating is in progress. Ammonia is set free by the lime in the skins. It is then neutralized by acids produced by bacteria, and thus acts as a carrier for the acids, and the bate remains in a nearly neutral condition. As the lime increases in the liquid the action of the bacteria diminishes, and finally the alkalinity becomes too great to allow the bacterial or chemical action to proceed further.

It will be noted that the concentration of the active salts in the bate is extremely small. If the amine compounds be assumed to consist of ethylamine butyrate or lactate, the concentration of the solution is approximately 1 grm. per litre; it is important that the concentration of salts should not greatly exceed this amount. I have found by experiment with ammonium chloride solutions, that the best reducing action is provided by a concentration of 0·7 to 1 grm. NH4Cl per litre; if the concentration be raised to 2 or 3 grm. per litre, the skins become “leathery” and do not fall properly. The alkalinity must not be greater than 3–5 c.c. N/10 per 100 c.c. bate, for the bate to work at its best.

Solution of Skin Substance during the Puering.—The determination of the total skin substance dissolved by the puer is best done by Kjeldahl’s method before and after the goods.36

The difference in the total nitrogen found multiplied by 5·6 gives the amount of skin substance dissolved by the bate, assuming the amount of nitrogen in the dry ash-free skin to be 17·8 per cent. If very great accuracy be required, a small correction for nitrogen, brought into solution from the puer itself, is necessary.37 This correction must be ascertained for the particular puer used by actual experiment.

The following figures give the results in grams per litre obtained in the puering of sheep grains. 50 c.c. of the filtered puer liquor are slightly acidified with sulphuric acid, evaporated nearly to dryness and Kjeldahled in the usual way.

Mean | ||||

| Total nitrogen before skins | 0·2632 | 0·2604 | ||

0·2576 | ||||

| " " after " | 0·4928 | 0·4844 | ||

0·4760 | ||||

| Difference | — | 0·2240 |

Equivalent to 1·254 grm. skin substance per litre. This was somewhat over a kilogram of skin substance for the paddle in question, and equal to 1 per cent. of the dry ash-free skin.

As to the differentiation of the dissolved skin substance into albumoses, peptones, monamino acids, diamino acids, ammonia, etc., a modification of Stiasny’s method38 for the examination of soaks and old limes may be used.

The method is based on the fact, discovered by Schiff, that formaldehyde reacts with amino acids, forming methylen-amino acids, which are distinctly acid and allow a sharp titration with phenolphthalein as indicator, while the amino acids themselves react almost neutral. Soerensen has worked out a method on this basis for the determination of different amino acids, and for tracing the course of hydrolysis of albuminous matters.

Instead of using phenolphthalein as an indicator, the electrometric apparatus of Sand (see p. 76) is employed. 50 c.c. of the filtered puer liquor are put into a beaker, the hydrogen electrode is immersed in the liquor, and the potential difference (P.D.) observed; this gives the hydrogen ion concentration of the solution. 10 c.c. of neutral formaldehyde solution (40 per cent.) are added, and the P.D. again observed; it will be found to diminish rapidly, but soon becomes constant, indicating that the reaction is a quick one.

The increase of acidity, as shown by the lowering of the potential difference, is due to the acidity developed by the combination of the formaldehyde with the amino acids forming methylen-amino acids of appreciable hydrion concentration. The amount of such acids is estimated by titrating with N/10 caustic soda solution until the P.D. rises to the same voltage as that originally found. The following figures were found in an experiment:—

Original Puer Liquor | The same After Goods | ||

| π (volts) | 0·61 | 0 | ·69 |

| π after 10 c.c. formalin | 0·53 | 0 | ·54 |

| N (Kjeldahl), grm. per litre | 0·3136 | 0 | ·5936 |

| Increase of N | — | 0 | ·2800 |

| N/10 soda for 50 c.c. to original voltage | 7·0 | 11 | ·6 |

| c.c. increase N/10 soda | — | 4 | ·6 |

| ∴ 1 c.c. N/10 soda = mg N | — | 3 | ·05 |

A preferable method is to add decinormal acid or alkali to the original liquor until the P.D. of 0·69 is reached, at which point the liquor will be neutral to phenolphthalein, and, after adding formaldehyde, to titrate with N/10 soda until the P.D. of 0·69 is again reached.

The factor which connects the amount of decinormal soda required for the titration, after the addition of formaldehyde, with the total nitrogen as determined by Kjeldahl’s method, will afford information as to the extent of the hydrolysis undergone by the proteid matter, in the same manner as Stiasny (loc. cit.), has proposed to differentiate the dissolved proteid matter in lime liquors. As hydrolysis proceeds the percentage of nitrogen in the molecule increases, being at its maximum in the ultimate nitrogenous product ammonia; the factor, therefore, becomes less as hydrolysis becomes more advanced.

| For ammonia 1 c.c. N/10 soda | = | 1 | ·4 mg. N |

| " hydrolized gelatin39 | = | 2 | ·9 " |

| " Witte peptone completely hydrolized39 | = | 3 | ·6 " |

| " lysin | = | 2 | ·8 " |

| " arginin | = | 5 | ·6 " |

| " histidin | = | 4 | ·2 " |

We may conclude that the skin substance dissolved in the puer liquor is hydrolized almost as completely as gelatin is by boiling with sulphuric acid.

I have previously pointed out that dilute acids dissolve a certain amount of skin substance (see p. 157), and in this connexion, Dr. Georges Abt has given me the results of some experiments, on the solubility of skin in various organic acids, which he made in Vienna. Pieces of skin, weighing 40 grm. in the wet state, were allowed to remain for one month in N/10 solutions of the acids. The N was then determined, by Kjeldahl’s method, with the following results, expressed as per cent. of the wet skin dissolved:—

| Per cent. | ||

| Acetic acid dissolved | 0 | ·645 |

| Lactic " " | 2 | ·27 |

| Butyric " " | 0 | ·577 |

| Formic " " | 1 | ·47 |

It will be seen that butyric acid dissolved the least amount of skin, lactic acid dissolving close upon four times as much.

Scud.—A certain amount of skin substance comes away in the “scud.” This is the liquid squeezed out of the skin by the pressure of the scudding knife after puering.

The liquid has the same composition as the puer liquor out of which the goods have been taken, and in addition contains large quantities of pigment granules, wool roots, and some skin substance, which together constitute the so-called “filth” of the skin. Analysis of a scud from English sheep grains showed only 0·164 per cent. N, equivalent to about 1 per cent. skin substance (9·15 grm. per litre). Fat, 7·9 grm. per litre.

Eberle and Krall have recently40 analysed the fatty matter which adheres to the men’s knives in scudding lamb skins for gloving work. They obtained the following results:—

Per cent. | ||

| Water | 29 | ·7 |

| Fat | 42 | ·0 |

| Fatty acids combined with lime | 6 | ·6 |

| Albuminous matter soluble in water | 3 | ·8 |

| Hair and insoluble albuminous bodies | 14 | ·4 |

| Ash (containing 57 per cent. CaO) | 3 | ·5 |

The fat had a—

| Melting-point | 40–44° |

| Saponification number | about 121 |

| Iodine number | 31·6 |

| Hehner value | 91·9 |

| Acid value | 9·3 |

Dr. Fahrion found, in a sample of the fat extracted with ether:—

Per cent. | Iodine number. | |

| Unsaponifiable | 47·6 | 27·3 |

| Fatty acids (sol. in petrol ether) | 39·3 | 30·2 |

| Oxy acids (sol. in ether) | 13·5 | 13·4 |

The figures obtained for the fat therefore agree closely with those for wool fat.

Action of the Bird-Dung Bate.—The depleting action of the pigeon- and hen-dung bate is very similar to that of the puer, or dog-dung bate; but the bating process with these materials, as we have seen (p. 18), is carried out at a lower temperature, and is consequently more prolonged. The principal difference between the two bates appears to be a chemical one, due to the fact that bird dung contains all the urinary products which are present only to a small extent in the dung of mammals. In birds uric acid is the chief stage in nitrogenous katabolism, the mechanism of its formation being a process of synthesis in the liver (Halliburton). Urea is also present in considerable amount, and does not appear to be so easily decomposed as the urea in animal urine.41 As we shall show in the next chapter, urea, and probably also urates, greatly facilitate the permeability of gelatine, and to this fact may be ascribed the more gradual action of bird-dung bates. If we attempt to bate hides with dog-dung, the grain of the hide is found to be attacked and destroyed before the bate has penetrated to the interior of the hide. On the other hand, a bird-dung bate may be used at a temperature of 38° to 40° C. for the puering of skins destined for light leather, but its action is not so favourable as that of the puers.

Composition of Bird Excreta.

— | Pigeon | Hen | Duck | Goose | |||

| Moisture | 58·32 | 56·08 | 60·88 | 46·65 | 77·08 | ||

| Organic matter† | 28·25 | 19·56 | 19·22 | 36·12 | 13·44 | ||

| Phosphates | 2·69 | 2·54 | 4·47 | 3·15 | 0·89 | ||

| Carbonate and sulphate of calcium | 1·75 | 3·08 | 7·85 | 3·01 | 2·94 | ||

| Alkaline salts | 1·99 | 0·82 | 1·09 | 0·32 | |||

| Silica and sand | 7·00 | 17·92 | 6·69 | 10·75 | 5·65 | ||

— | 100·00 | 100·00 | 100·00 | 100·00 | 100·00 | ||

| † Containing nitrogen equal to ammonia | 1·75 | 1·21 | 0·74 | 0·85 | 0·67 | ||