WITH

NOTES ON THE METHODS USED FOR THE

DISTRIBUTION OF ELECTRICITY.

BY

KILLINGWORTH HEDGES,

MEMBER OF THE INSTITUTION OF CIVIL ENGINEERS, AND OF

THE SOCIETY OF TELEGRAPH ENGINEERS AND ELECTRICIANS.

LONDON:

E. & F. N. SPON, 125, STRAND.

NEW YORK: 12, CORTLANDT STREET.

[All rights reserved.]

The art of lighting by Electricity practically dates from ten years ago, and it has during that period received the constant attention of both Electrical Engineers and others, who have applied the greatest scientific knowledge. The result of all this energy appears to be discouraging. Five hundred thousand pounds have been subscribed to carry on the business, and it is doubtful whether the companies which survive have a market value of one-tenth of that sum. The experience may have been bought too dearly, but the era of Central-Station Electric Lighting, which has now commenced, ought to re-establish the position of Electricity in financial circles, and afford a safe and profitable outlet for the surplus capital of the investor who buys gas and water shares to pay four per cent.

The distribution of electricity from a central-station, which was the subject of Sir William Siemen’s Presidential Address at the Society of Arts in 1882, is not only accomplished from the scientific point of view, but is also a commercial success: the power of flowing water, or [Pg vi] the potential energy stored up in coal, wood, or other fuel, can be utilised for lighting our streets and houses at night, and during the day may be transmitted by means of electricity in the easiest possible way, and supplant the gas-engine for driving small machinery.

A paper entitled “Central-Station Electric Lighting” was contributed by the Author to the Institution of Civil Engineers, and was published in Part II. of the Minutes, 1886-87; the subject-matter has been extended and brought up to date, with the object of giving a description of the systems which are practically employed in Central-Station Lighting at home and on the Continent. Details respecting the generating plant at these stations are omitted on purpose; technical terms would also be avoided if possible; failing this, it is hoped that the accompanying Glossary will explain what is unfamiliar.

The amendment of the Electric Lighting Act of 1882 has given a fresh stimulus to the industry, and many new enterprises for distributing electricity from Central-Stations are being prepared, and it is to be hoped that the public will profit by former experience, and will discriminate between the good and the bad schemes which will be offered to them.

The organizing facilities possessed by Gas Companies make it desirable that they should follow the example of the American Companies, and take up the business of supplying electricity. The existing powers of [Pg vii] private companies might have to be altered, but those municipal authorities who own the gasworks could certainly distribute electricity from a central-station, which might be installed at the present works. Local authorities have certain advantages over private companies owing to the purchasing clause of the Electric Lighting Act, also the power to borrow money under this and the Local Loans Act of 1875; should there be no department to carry out the business of supplying electricity, the generating plant could be maintained and worked by a contractor for a fixed annual sum.

The remarks of Lord Herschell that the “electric light is more used in the South Sea Islands than in this country” ought to be taken as not so much referring to want of enterprise on the part of capitalists and engineers, but to the Electrical Facilities Act of 1882, which has been appropriately termed a very “boa-constrictor.”

25,Queen Anne’s Gate,

Westminster, S.W.

September, 1888.

AS the term “central-station” associates itself with some pretentious building, such as a railway terminus, it may be advisable to remark that the similarity is only in the words, and that central-station is an abbreviation of central generating station, or building designed to contain the plant for the public supply of electricity. In the early days of electric lighting the transmission of electricity to a distance was considered an impossibility; we find the late Sir William Siemens, in his Presidential Address at the Society of Arts on the occasion of the opening of the session in 1882, stating “that a quarter of a mile in every direction from the lighting station was the area which would be as much as could be economically worked;” and, in order to tap the most paying district, it was proposed to establish a station in the most central spot. Sir William Siemens suggested the utilisation of the public squares, which could be excavated to a depth of twenty-five [Pg 2] feet, and then arched over to the existing ground level, and in this covered space the engines, boilers, and dynamos were to be fixed; the only erection above the surface was the chimney, which was to be of ornamental design and combined with the ventilating arrangements of the subterranean chamber. The great inventor, who so ably filled the presidential chair at the meeting where these words were spoken, would be astonished to find that in London one electric lighting company has already erected seventy miles of overhead wire, and that customers are supplied miles away from the so-called central-station. The changed position of electricity is due to the introduction of the transformer by Goulard, who showed, at the Turin Exhibition of 1884, that a high-tension current could be transformed into a low-tension working current of safe potential, fifty miles away from the generator, in a successful and economical manner, and that the generating station might, therefore, be located outside the area to be lighted. In large cities this is a great advantage, the value of land often precluding the erection of a big station in the working area; for this reason small stations are often arranged in basements, under a large building, which are, as a rule, specially designed. This plan is somewhat similar to that adopted in the United States, where it is not unusual to find a successful installation in a basement and sub-basement, the general arrangement being of similar character to the engine-room of a steamship.

A station is being erected in Philadelphia on a ground space of 72 feet × 100 feet, which is to supply 60,000 lights; the building is [Pg 3] six-storied, the dynamos are on the first floor, the boilers on third, the coal stores on fourth, and the offices on the fifth.

The term “block station” is also used in the United States and in Germany, and is applied to an installation which lights a group of buildings or block without crossing any streets, and consequently without having any wayleave or permission from local authorities.

An American electrical engineer graphically sums up this question in the following manner:—“There are two ways of starting a central-station for electric lighting—the investment or the speculative plan, or the fair means or the foul. The first has its legitimate end, but the latter is the border ruffian or money-or-your-life policy, which enters a territory already sufficiently covered, not for fair competition, but to make money by being bought out.” Happily, here, we have at present only to deal with the first plan, and the question naturally arises, “Is electric lighting a paying investment?” It certainly will not be if the object in view is only to compete with gas in a limited district where perhaps it is being sold at 2s. 6d. per 1000 feet, for, as long as there is a ready market for the coke and other by-products, gas will remain in possession of the field. The heat from gas, which is found so undesirable by the wealthier classes, is advantageous to those who [Pg 4] perhaps cannot afford a fire; in fact, gas has been truly called the “poor man’s friend,” and, until electricity can be supplied at a nominal price, it will be useless to expect any revenue from the poorer districts of large cities. Quite an opposite result may be looked for when the electric mains are laid at the doors of the wealthy householder, or through the business neighbourhoods. Shop-owners especially are found to immediately take up electric light, from the fact that no fumes are given off to destroy goods or tarnish silver or gilding, and because it can be so easily applied in a shop window so as to efficiently light the contents without producing shadows. The great object to be aimed at in selecting a district to be served from a central-station is a “constant demand,” and for this reason it is advantageous to include a business neighbourhood with shops, public-houses, and restaurants, which require the light for a definite period every day, and probably will each take more than double the amount of an ordinary dwelling-house; in fashionable neighbourhoods especially, it is not unusual to find a large number of houses vacated at the close of the season, the interest on that portion of the electric system which is unemployed will have to be set against the profits of other periods of the year.

The number of gas lights which are actually used at one time in a house is found to average only two-thirds of the total number fixed, and with electric light this number is reduced to one-half; economy is at once the rule with electric light, partly because of the novelty of the illuminant, and also on account of the facility of lighting and extinguishing by simply turning a tap or switch. The number of hours artificial light is wanted in a residential district may be taken at [Pg 5] about 1000 hours per annum, that is to say, the light is required for about four hours a day in winter and two hours in summer; this amount is very much exceeded in clubs, shops, and even in large houses, but 1000 hours is a safe figure, and, if the supply is taken by meter, an annual payment equivalent to 1000 hours’ supply should be a fixed amount to be paid for, whether used or not. Mr. Crompton estimates that a Londoner, who is a tenant or owner of a house having three reception rooms, ten bedrooms, and usual offices, spends about £25 a year for his lighting, which is made up as follows:—gas bill, £15; lamp, oil, candles, matches, about £10. There would be about fifty burners fixed; and, supposing fifty electric lights to be substituted, he could be supplied with electricity for £25 a year, at a fair profit to the supply company if they charged 8d. per Board of Trade Unit, as practice has shown that the total number of lamp-hours with fifty electric lamps is not more than sixty-two, so that two Units,[1] or 1s. 4d. per day, would be sufficient for the lights he would require.

The diagram, Fig. 1, taken from a London residential district, shows how the number of lamps on at one time vary; the district is supposed to be wired for 10,000 lamps, and the plant as equal to the supply of 600 kilowatts, or 600,000 watts; the number of lamps is small until about 3 o’clock, when it gets dusk on a winter afternoon; it then increases steadily until about 6.30 o’clock, when the curve goes up with a rush; about this time a great number of people are preparing for [Pg 6] dinner, and probably the lights are on both in the dining-room and bedrooms. The curve falls, and at about 8 it begins to sink gradually until 10 o’clock; a great many people appear to go to bed about this time, but a few sit up to 1 o’clock; until 6 the next morning hardly any supply is taken, when the servants get up and prepare the rooms for the day. The diagram, Fig. 2, is taken from the Edison Company’s central-station at Cincinnati, and agrees fairly with the London demand for light. Another interesting fact has been ascertained from the observations taken at the Mauer Strasse station in Berlin, namely, that the output varies with the temperature, it goes up or down with the thermometer. The reason is easily explained; gas is laid on side by side with the incandescent lamps, and the burners are first lighted when it is cold to warm the apartments; in warm weather the electric light alone is used. From these and other diagrams the very important [Pg 7] fact has been obtained, that the average daily output of a station throughout the year is less than one-third of the total capacity of the generating machinery, so that, although the station from which the diagram in Fig. 1 was taken could maintain 10,000 16 candle-power lamps simultaneously alight, the average daily output of electricity would only equal 3500 constantly lighted; and, as the first cost of the station is dependent on the size of the plant, the saleable output is the important factor which governs the profits.

The well-known expression “per 1000 Cubic Feet” is not applicable to electric light, and, instead, the Board of Trade Unit is employed. By [Pg 8] this term Unit is meant the quantity of energy contained in a current of 1000 Ampères flowing under an Electro-motive Force of One Volt during One Hour. In the early days of electric lighting the term Volt-ampère was used, and has for convenience sake been shortened to Watt; that is, the Volt or Unit of Electro-motive Force (or pressure) is multiplied by the Ampère or Unit of current.

The Board of Trade Unit is, therefore, a Thousand Volt-ampères or Watts per hour.

For example: 16 candle-power Swan lamps are assumed to take 60 Watts, which, if the electrical pressure is 100 Volts, would mean a consumption of 0·6 Ampère; and, as an Electrical Horse-power equals 746 Watts, 12·4 lamps should theoretically be obtained per Horse-power, which is, however, reduced in actual practice to 10 at the most, often less.

The charge per Unit supplied by meter varies in England from 1s. to 7d.

| Price for electric light. |

Equivalent price for gas of equal light. |

||||||

|---|---|---|---|---|---|---|---|

| s. | d. | s. | d. | ||||

| 1 | 0 | per Board | 6 | 10 | per 1000 cubic feet. | ||

| 0 | 9 | of | 5 | 1½ | ”” | ||

| 0 | 7¼ | Trade | 4 | 2 | ”” | ||

| 0 | 6 | Unit. | 3 | 5 | ”” | ||

These prices, of course, include the manufacturer’s profit as well as the loss in transmission through the mains and expenses of connecting up to the consumer. The actual manufacturing cost of a station [Pg 9] maintaining 10,000 lights should not be more than 3d. per Unit, or equivalent to gas at 1s. 8½d. per 1000 cubic feet.[2]

As petroleum lamps are used for the street lighting of many foreign and colonial towns, the question arises, “Will it pay to substitute the electric light?” Comparing the light given by a kerosene or petroleum lamp with that from the incandescent electric lamp, the cost is greatly in favour of oil; and, in fact, where the price of kerosene is under 1s. per gallon, electricity cannot compete if labour is cheap. On the other hand, the trimming, lighting, and keeping in order of a number of lamps scattered over a large area greatly augments the working cost, to which must be added the breakages of chimneys, expense of wicks, also the danger of fire. It is the safety of electricity which has caused it to supplant oil both for public and private lighting in American cities; even where the price of kerosene is not more than 6d. per gallon there is a demand for the electric light, which is by far the dearer illuminant, after making a liberal allowance for labour in cleaning, filling, and lighting the oil lamp, also for depreciation of the burners.

Electric lighting can be obtained by means of arc or incandescent lamps. The arc light is now well understood to be caused by the extremely high temperature of the end of one or both the carbon [Pg 10] electrodes. The voltaic arc, Fig. 3, is formed by the minute particles of carbon in a high state of combustion which the current appears to break off and carry from one electrode to the other, the light, however, being mainly due to the incandescence of the crater shown in Fig. 3 on the upper carbon. In the incandescent or glow lamp light is produced by the passage of a current of electricity through a continuous fine thread or filament of carbon which becomes white-hot, the destruction of the filament being prevented through its enclosure in a glass bulb from which the air is exhausted. Figs. 4 and 5.

The first method is suitable for the lighting of streets where a high-class illumination is required; also will be wanted for the external lighting of shops, public-houses, and places of amusement, so that arrangements must be made for arc lighting. The usual plan is to charge at the same rate per Unit by meter as the incandescent lamps, but to make an additional charge of 5s. to 7s. 6d. per lamp per quarter for rent, and a further charge of 3s. per week for cleaning and trimming.

The principal types are the Edison and the Swan, Fig. 4 and Fig. 5.

Incandescent lamps can be obtained to order from 1½ candle-power upwards, but the 16 candle-power (nominal 20) or the 8 candle-power (nominal 10) lamps are almost invariably employed. The latter give the best effect, and can be worked to 10 candle-power without much risk, [Pg 11] they take about 30 watts as against 60 watts for the 16 candles; and are not uneconomical, for nearly double the number can be worked with the same energy. A new type of glow lamp, called the “Sunbeam,” has been recently introduced, which contains a thick filament, and gives a light of from 200 to 1500 candle-power, and can be employed instead of an arc lamp with the same economy as the ordinary 16 candle-power type.

In estimating the annual cost of lighting, the renewals of lamps must be taken into account; and although some lamps have worked 3000 or even 4000 hours, a life of 1000 working hours is the highest average it is [Pg 12] safe to assume in practical work under even the best conditions, that is, using secondary batteries and never over running. The average life of 130 lamps on H.M.S. troopship Malabar was 3799 hours each, the shortest life being 638½ hours for 18 yard-arm lamps of 32 candle-power. If the current is allowed to fluctuate, the average life would be very much less; it is an unsettled question whether long-lived lamps are really economical, by reason of the blackening of the globes, which takes place after the lamp has been worked some time, and is probably due to small particles of carbon thrown off from the filament being deposited on the glass. It has been suggested that attrition of the filament is going on all the time the lamp is at work, and that the heated atoms striking against the filament may account for the blackening, in that the mean free path of the atoms would be greater in a perfect vacuum than in the air, consequently they would abrade the filament with considerable force. If lamps were sold at 1s. each instead of 3s. 6d., which is now the price for not less than a thousand, it would be more economical to change them at the first signs of blackening, even if the life did not exceed 500 hours.

The diagram, Fig. 6, has been so arranged that the amount of light required in a given district can be ascertained for any period of the day or night; it has been calculated from the observations taken daily at one of the Berlin central-stations by the engineer to the company.

Six hundred and forty watts are assumed, for the purposes of the [Pg 13] diagram, to be the equivalent of a horse-power, instead of 736, as the German electrical horse-power is 736 watts instead of 746 watts.

The table, Fig. 6, has two vertical scales, A and B, each giving the [Pg 14] kilowatts[3] and corresponding horse-power. A is drawn to a scale ten times greater than B, with the object of noting the smaller amount of lights required for street illumination. The horizontal line is divided into hours, and represents a day’s lighting in the middle of December and the end of July, so as to show the maximum and minimum amount of current that will be required. In the lighting of a town there are two classes of illumination, the amount taken by the public, which is uncertain, and that employed for street lighting, which is a known quantity.

The curves, II and II A, represent the private lighting of houses, hotels, theatres, and shops of different kinds in December and in July, the curve, II A, being in dotted lines clearly shows what a vast difference there is in the amount of light, and consequently the amount of energy required in the generating station, as compared with curve II, which is taken when the days are longest.

The rectangles, I and I A, show the street illumination, and are drawn to suit scale A; half an hour after sunset all the lamps are turned on, and the work reaches its maximum suddenly, and continues the same until 12 o’clock, when, according to the municipal decrees, it either falls one or two gradations until half an hour before sunrise, when all the lamps are extinguished. The calculations are based on the assumption of 640 watts to the horse-power, instead of 736, which is the theoretical efficiency of a German horse-power.

If a number of diagrams are taken on this method for different periods [Pg 15] of the year, the constant work can be ascertained. This knowledge is most valuable when calculating the most economical area for the mains, which is then easily accomplished by means of Forbes’ tables, which are based on Sir William Thomson’s well-known rule.

The lines, 2 and 2 a show the constant work at the same two periods of the year from which the diagrams are taken. The constant work at the end of December will be found to amount to 20 per cent. of the total work, and that at the middle of June to 15 per cent. By summing up the average work for all the days in the year we obtain the cost per annum, and adding to this the expense of management, interest, &c., and knowing the local conditions, we can fix what proportion of the day’s work is admissible as loss. With the Edison system at Berlin, 5 per cent. is taken as average loss; thus, at the end of December, it amounts, with the maximum number of lights, to 18·8 per cent., and with the minimum to 1·1 per cent.; in the middle of July the maximum is 15·8 per cent., and the minimum 0·5 per cent. The dynamos must, of course, be of sufficient power to be able to overcome this loss, which only shows itself periodically; therefore the generating plant may be constructed to give, nominally, 20 to 30 per cent. less than the maximum work, and be capable of being pushed to the full amount for a short time only. [Pg 16]

Uncontrolled financial speculation, aided by the stringent clauses of the Electric Lighting Act of 1882, have been a great deterrent to the extension of old or the introduction of new schemes for the supply of electricity to the public in the same manner as gas. The President of the Board of Trade, replying to a question in the House of Commons, said that, “since the passing of the Electric Lighting Act of 1882, fifty-nine provisional orders and five licences had been granted to companies, and fifteen provisional orders and two licences to local authorities. He was not aware that, in any single case where these powers had been obtained, they had been exercised.” Up to the present time no company supplying electricity has been under the necessity of applying for compulsory powers, and has either obtained permission from the local authorities to take up the streets, or has carried the electric mains over the houses, and, regardless of the question of overhead wires, has depended on wayleaves granted by the too-confiding householder, who has no idea that his roof is supporting a cable weighing 1¾ tons to the mile.

An amendment of the Act of 1882 has passed both Houses without hindrance, and has received the Royal assent. It provides that in the case of Provisional Orders the period after which the undertaking may be bought up by the Local Authority shall be extended from twenty-one to forty-two years, and that portion of the previous Act which referred [Pg 17] to the compulsory purchase of the undertaking by a local authority at the end of the term has been altered, and more favourable terms given to the electric companies.

On the Continent, and in the United States, where each city may be said to legislate for itself in matters relating to the general welfare of its citizens, the electric lighting industry is in a very different position, and central-stations are either established or about to be started in every important town. There were, in 1887, 121 Edison central-stations alone, supplying over 323,000 incandescent lamps, and paying dividends from 6 to 14 per cent. The Westinghouse Company, who use a transformer system which is a modification of the Goulard and Gibbs, have a hundred stations, maintaining 191,000 lamps, although the first Westinghouse plant was put down only three years ago. The progress in the United States is so rapid, and there are so many successful applications of central-station lighting, that the subject becomes too large to be even summarised, so that it is proposed to treat in the following pages with some of the principal installations on the Continent and at home.

Travellers abroad are accustomed to find electric lighting installed in the most out-of-the-way places, especially in Switzerland, where water power is abundant and is utilised to generate electricity, so that in small hamlets arc lighting is often employed, and the visitors to the local hotel will find it lit throughout by electricity. Electric light stations in England are, with one exception, small in comparison with those on the Continent. The most important is that at the Grosvenor [Pg 18] Gallery, London, which has increased from small beginnings until it now supplies 20,000 glow lamps on sixteen circuits, the total length of which is seventy miles. The next largest, which have been in practical work for some time, are the Brighton and Eastbourne stations, from which small installations of glow and arc lights are maintained in various districts of the two towns. That the question of cost or trouble, and the annoyance of machinery when erected in a dwelling-house, do not altogether prevent the adoption of a superior light, is clearly proved by the increasing number of householders, who, after waiting in vain for electricity to be brought to their doors, have set up the plant necessary to produce it themselves, and find no practical difficulty in doing so. There are also many important public works where electric light has been exclusively adopted. For instance, at the Tilbury Docks there are 1350 glow and 80 arc lamps, distributed over an area of 300 acres, and including the lighting of an hotel, dock sheds, warehouse, signal-boxes, and offices. The London, Chatham, and Dover station at Victoria has also been electrically lighted for the past three years, the current being obtained from a central-station, which was erected for the purpose of supplying electricity to the Victoria district, and for which a provisional order was obtained. This, however, has since been abandoned, although £16,000 had been expended on plant and buildings by the promoters, who preferred to postpone the scheme rather than to submit to the onerous 27th clause of the Electric Lighting Act. Another still larger installation has been [Pg 19] put down to supply electricity to the Paddington station and district of the Great Western Railway, as far as Westbourne Park. It embraces an area of sixty-seven acres, and is lighted by 4115 glow and 98 arc lamps. The system adopted is that designed by Mr. J. E. Gordon, and has now been successfully worked for some time; but the many accessories which are introduced, such as telephones, telegraphs, and indicators, make it complicated in comparison with gas, or even with the ordinary electric light systems. The current is generated by two dynamos, each weighing 45 tons, and having revolving magnet wheels 9 feet 8 inches in diameter, 22 tons in weight, a third machine being kept in reserve. These dynamos are separately excited, and produce alternating currents. The electricity is led to a large switch-board for distribution throughout the district by means of five sub-stations; and from this board there branches a double system of mains, which run everywhere side by side, one-half the mains being connected to the first machine and one-half to the second, so forming an excellent arrangement for the prevention of total extinction of the light. The mains running to the sub-stations are on the divided system, which is introduced for the purpose of saving copper, as in a solid cable the loss of pressure is greatest when the full number of lamps is on, and decreases as the lamps are extinguished. With the divided main system it is intended to follow out Sir William Thomson’s formula, which equates the value of the loss of head, and the interest on the saving on the copper. If for a certain main this formula shows that a fall of 20 per cent. is the [Pg 20] most economical condition for working, then, since by the divided main the pressure can be kept within a variation of 2 per cent. at the distant end, it follows that a considerable saving can be effected over an ordinary solid main. Special arrangements are adopted at Paddington to keep the pressure constant, a fall of potential being allowed for; thus at the engine-house the pressure is 150 volts, in the passenger station it is 120 volts, and at Westbourne Park it is 100 volts. The arc lamps are fed by the same mains, and are arranged two in series.

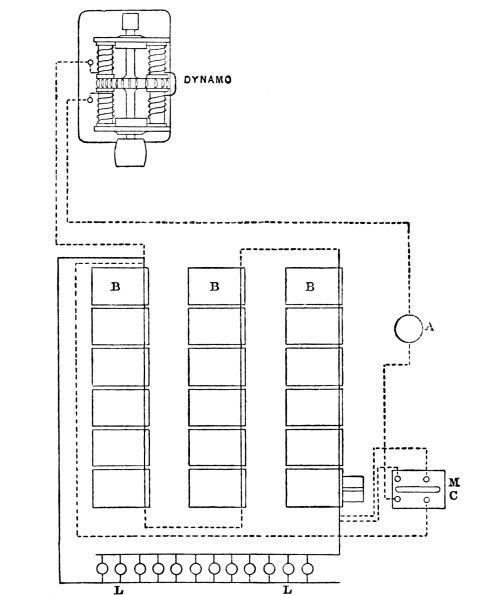

A small installation at Kensington Court, erected two years ago, for the purpose of supplying the houses in the immediate neighbourhood, has rapidly developed, and underground mains have been led in many directions from the station, and a constant service of electricity is provided for by means of secondary batteries. As this is the first practical exposition of the secondary batteries’ system of distribution, it is proposed to describe the installation under that head. Central-stations are also at work in Liverpool, Leamington, Taunton, Exeter, and there are also five large installations nearly completed in London, besides the Kensington Court station, all of which will probably be in full swing before the end of the year.

Electric Lighting from Central-Stations is now practically carried out on five different methods.

The problem of electric lighting from central-stations is comparatively easy if an area can be obtained immediately surrounding, and within a short distance of, the station, with a right of way for laying down the electric mains direct. This happy state of affairs has not yet been attained, consequently the generating station has more often to be in an out-of-the-way corner of the district to be lighted, and it would be financially impossible to use low-tension currents with correspondingly large mains. The difficulty has been overcome in several ways by the use of high-tension currents in the mains, and has led to the adoption of secondary generators or transformers of electricity, which by induction supply a current of low potential in the house-service. The first to make this plan a practical success was Mr. Goulard, to whom the honour of the introduction is due, although his claims as the first inventor have been recently upset by the decision of the Courts.

The relative economy of the supply of electricity by the use of a transformer is clearly shown by the following diagram, Fig. 7. A, B, and C give proportionately the area of cross section of the total mass [Pg 22] of copper necessary to supply 5000 16 candle-power glow lamps situated at a mean distance of 4000 feet from the dynamo. A refers to the Edison “three-wire” system, working at a potential or electrical pressure of 200 volts with a fall of potential or loss of energy in the distributing feeders of 10 per cent., average distance from dynamo 4000 feet—the usual conditions on which this system is worked. B shows the size of conductor required for the same work in an installation based on the transformer system, potential 1000 volts, allowing 2·5 per cent. loss in the supply mains—only one-fourth as much as in the direct Edison system at the same average distance from dynamo. If this loss were increased to 10 per cent., and made equal to that in the direct system, viz. 10 per cent., the size of the conductor would be that shown at C.

The graphic diagram, Fig. 8, demonstrates what the relative cost would be with each of the three conditions just named.

[Pg 23] Mr. Goulard’s first practical application of the secondary generator in this country was the lighting of the Underground Railway Stations, in 1883, from Edgware Road to High Street, the generating dynamo being fixed at the former place. These experiments, which were made by Mr. Kenneth Mackenzie, attracted considerable attention at the time, but it was not until the report of the jurors to the Turin International Exhibition in 1885 was published that companies were formed to instal the Goulard system for lighting an extensive district.

The principle underlying all transformers is that of the induction coil invented by Ruhmkorff in 1842, but described by Faraday in his “Experimental Researches,” published in 1831-2.

Fig. 9 is a diagram of the ordinary induction coil; on a central core is wound a short length of thick wire called the primary, and again over this is wound a greater length of fine insulated copper wire which forms the secondary coil. On sending a low-pressure current from the [Pg 24] generator round the thick wire, a much smaller high-tension current is induced in the secondary. A contact breaker is employed to make and break the current, or, as in the early instruments, a commutator may be used to produce the alternations. When used as a transformer the action is reversed, that is, a high-tension current is passed through the primary coil, which is composed of a wire of small sectional area, the high-pressure main connected to the dynamo also being small as compared with the distributing cable leading from the transformer, which, acting as a step-down induction coil, converts the electricity into a safe working pressure.

Fig. 9 a shows the arrangement of the two separate and complete circuits. D is the dynamo, P the primary coil, S the secondary, and L the lamps arranged in parallel.

It is hardly necessary to go into the technical details of the various improvements which have led up to the modern type of transformers; they are summarised by Mr. Kapp into two classes:—

No. I. are those in which the copper coils are spread over the surface of the iron core enveloping the latter more or less completely; and No. [Pg 25] II. in which the core is spread over the surface of the copper coils forming a shell over the winding.

The original Goulard and Gibbs secondary generator was of the core transformer type, it had an open magnetic circuit and cores which could more or less be inserted into the coils so as to regulate the electro-motive force of the secondary circuit. The transformers were constructed with a number of copper disks or washers; these were placed alternately primary and secondary in a vertical frame, through the centre of which an iron core was fixed, consisting of a bundle of straight iron wires. The core was movable in the coil in the manner of the well-known induction coils, and thereby the electro-motive force of the secondary current could be adjusted. In their latest design the coils are circular in plan and rectangular in section and are surrounded by groups of U-shaped soft iron stampings slipped over from both sides and held together by two circular cast-iron plates with a central bolt. The magnetic lines of force pass through the core, in at one end and out at the other, and are then more or less disseminated through space; it will thus be seen that the path of the lines lies partly in iron and partly in air, and, since air has about seven hundred times more magnetic resistance than iron, it is evident that the number of lines created with a given current must be considerably smaller than would be the case if the path of the lines contained iron only. This constitutes the improvement in the Zippernowsky-Deri-Blathy system of transformer, which has coils similar to the Goulard, but with [Pg 26] the iron of the core applied in the form of a ring-shaped shell, surrounding both coils completely. This arrangement can best be described by comparing it to a Gramme armature, in which the copper and the iron have changed places. Imagine what is usually the core in an armature replaced by the primary and secondary coils, and, instead of the winding of insulated copper wire, wind iron wire around the coils, and one of these transformers is the result. In consequence of the lower magnetic resistance of the Class II. transformer, as compared to that of Class I., the electrical output obtainable with equal weights of copper and iron appears to be considerably greater in the former apparatus. Professor Feraris, of Turin, has published some of the results of comparative experiments made with Classes I. and II. and finds that the coefficient of induction is 3·6 times as great with the [Pg 27] latter as with the former. There are many varieties of transformers in the market which closely resemble each other; one of the most practical is that designed by Kapp and Snell, of which Fig. 10 is an illustration. U-shaped stampings form the shell and the cores are laid in the double trough. The cover of these troughs is formed from the metal removed from the interior of the stampings, and the whole is held together in a cast-iron frame so arranged as to allow air to circulate through the core and round the coils. The price of these transformers is about £4 per indicated horse-power, and the efficiency under the best conditions, namely, with full load, is, according to Professor Ayrton, as high as 96 per cent., and when it is doing one quarter of the full work 89 per cent.

The installation at the Grosvenor Gallery, London, may be taken to illustrate Class I. or the practical working of distribution by means of transformers.

Fig. 11 represents the arrangement of primary and secondary circuits.

An alternating current is sent through the main L L¹, which is a closed circuit, and a small portion is drawn off wherever there is a secondary generator or transformer T; these instruments are placed in parallel between the conductors in the same manner as a glow lamp; neither main can be called positive or negative, as the current flows backwards and forwards many times in a second. The house wires M M [Pg 28] are joined to the secondary circuits, and are quite distinct from the main, which they do not even touch, although sufficiently near to receive an induced current alternating the same as the primary, but of a much lower electro-motive force.

| D, alternating current dynamo; | M M, secondary conductors; |

| E, continuous current dynamo for exciting; | T T, transformers; |

| L L¹, main primary conductors; | S¹ S² S³ S⁴ S⁵ S⁶, lamps in parallel. |

The Goulard transformers were used at first, but have been superseded by others designed by Mr. Ferranti; they are of the No. 2 kind, or shell type, and have a core of hoop-iron, on which the two coils are wound; the hoop-iron is then bent over, and the ends joined so as to enclose the coils. The machinery is fixed in a basement excavated under the Grosvenor Gallery; the foundations are of massive concrete, in which [Pg 29] stone supports for the engines and dynamos are embedded; the concrete does not touch the walls of the building, but a space of about 1 foot is left, which is filled in with clay; and by this simple plan all vibration of the machinery is isolated from the building. The power is obtained from two horizontal high-pressure engines, each of 600 indicated horse-power, in addition to the original two horizontal high-pressure non-condensing engines, each of 35 nominal horse-power, running at a speed of 55 revolutions per minute, which is maintained constant by means of a governor directly attached to the expansion slide-valve. The four engines drive on to a countershaft, which is cut up into lengths; each section is coupled to a dynamo and exciter by means of a conical friction-disk clutch; this permits of either length being started or stopped without interfering with the other. The speed of each engine is checked by means of a liquid speed-indicator, designed by the author. Two Ferranti alternating current dynamos, each capable of maintaining ten thousand lamps, are driven direct, one dynamo by each length of shafting: they are excited by two continuous current machines, the circuits from which are joined to a regulating apparatus, which by altering resistance keeps the electro-motive force of the large machines proportional to the number of lamps which are to be maintained. At present hand regulation is employed, but it is proposed to use automatic regulation, which will increase the life of the lamps, as they are severely tried by the variation of the current, which is more noticeable than in continuous current installations. The current from the machines is at a [Pg 30] potential of 2400 volts, and that from the transformers is 100 volts. The primary wire which carries this high electro-motive force does not enter the houses, as the transformers are, as a rule, fixed in the cellars, and from them the house branch is led in the form of a cable of fine wires, having a total diameter of 7/16 inch; the lamps, which are placed in parallel across this cable, are attached to single No. 18 or No. 20 B. W. G. wires in the usual manner. When first established, the transformers presented an element of danger, in that they, in common with all induction coils, were also condensers, and therefore a dangerous shock might be given to any one touching some unguarded portion of the lighting system. This has been prevented by the simple plan of connecting one of the terminals of every secondary circuit to earth, a method which, however, is not to be recommended, as it throws an additional strain on the insulation of the primary circuit; in fact, by earthing the secondary the insulation is practically reduced to one-half. A safety device should be inserted, which would come into operation on any leakage from primary to secondary, and immediately cut out the transformer.

The primary-current conductor is led overhead, and still remains an objectionable feature of the system, although the original trouble with the neighbouring telephones and telegraphs has been overcome. The primary circuit is a small carefully insulated cable of high conductivity copper wire, nineteen strands of No. 15 B. W. G. It weighs about 1¾ ton per mile, and is suspended, where it crosses the streets, on a steel bearer whose tensile strength is 1⅕ ton. It is so arranged [Pg 31] according to the droop of the cable that the strain of the bearer never exceeds 225 lbs., which means that the factor of safety is nearly 12 to 1. Double cut-outs or safety fuses, in many instances of the author’s design, are placed on each pole of the primary, at the point where it enters the house, so that, in the case of an excess current, the mica-foils would fuse, and all connection between that house and the supply main would cease.

Much credit is due to M. Goulard, who, in spite of great opposition to the use of his transformer system, initiated the Grosvenor Gallery installation three years ago. It has developed into not only the largest and most important central-station in Europe, but, as regards the transformer system, it supplies more lights than any in the United States. The original company has been taken over by the London Electric Supply Corporation, who are putting down plant capable of maintaining 30,000 lights, and are erecting another station at Deptford for 200,000 lights, which will be distributed by means of district transformers from mains, which it is proposed to run from Deptford through the Thames Tunnel and the Underground Railways. The electric current is supplied by meter at the price of 7¼d. per Board of Trade Unit, a price for light equal to gas at about 4s. 2d. per 1000 cubic feet.

The Eastbourne station is also on the transformer system. An alternating current dynamo, by Ellwell Parker, maintains a pressure in the primary circuit of 2000 volts, which is reduced by means of a Lowrie Hall transformer to a working pressure of 100 volts. There is a special arrangement for maintaining a constant electro-motive force in [Pg 32] the mains, independent of the number of lights in use. The mains are carried underground, and have so far given no trouble as regards the insulation of the high-tension current which passes through them. The Eastbourne company commenced by lighting the parade only with arc lamps, but now supply the incandescent light to all parts of the town, and enjoy the unique position of having obtained power from the corporation to run the mains in the streets prior to the passing of the Act of 1882. Another small station has been successfully worked for the last six years at Brighton; the group system was originally adopted, the lamps, both arc and incandescent, being placed in series or multiple series; the high-tension current is led through overhead wires in a very similar manner to the installation at Temesvar, Hungary, which is described at page 58, as an example of multiple series lighting. The extensions at Brighton are to be carried out on the transformer plan, which will necessitate the running of separate circuits, the intention of the company, however, being to gradually convert its whole system of supply to the transformer system. The Brighton Company has regularly paid dividends to its shareholders since its formation.

On the Continent the Goulard transformer is largely employed.

An important installation at Tours of 3500 lamps has been for some time successfully working. Another at Tivoli has some additional points of interest, in that the natural power of a waterfall is applied to generate electricity. Two turbines constructed by Escher Wyss, of [Pg 33] Zurich, having an available head of 29·75 feet, give 80 horse-power each, which is employed to drive two Siemens alternating current dynamos, separately excited by two small continuous current machines. Two distinct circuits of chromo-bronze naked wire, 3·7 millimetres in diameter, are run overhead, in the same manner as telegraph wires, through the town for a total length of about nineteen miles. The street lamps are fixed alternately on each circuit, so that one-half can be extinguished at a late hour without interfering with the others, or having to turn out individual lamps. The number of lamps used in the streets is two hundred glow lamps of 50 candle-power; also one hundred and twenty glow lamps of 16 candle-power for the illumination of the narrower streets. Arc lamps are also employed, as well as a large reflector lamp, the rays from which are turned on the Temples of Vesta and Sibilla. A house-to-house system is also being established, and the company which has put up the work proposes to utilise the falls of Tivoli in order to transmit 2000 horse-power for lighting purposes in Rome.

The firm of Ganz, of Budapest, who are the manufacturers of the Zippernowsky-Deri-Blathy system of transformers, have a similar installation completed in order to light a portion of Lucerne. The water power of Thorenburg 3·1 miles off, works the turbines, which drive two self-exciting alternating current dynamos of the Ganz type, similar to those shown at the Vienna Exhibition in 1884. The primary current of 38 ampères, at an electro-motive force of 1800 volts, is led [Pg 34] by four uncovered wires, each six millimetres in diameter, to the first station, which is 2·4 kilometres distant; here 1500 watts are taken off, and at 2·3 kilometres further 7000 watts are utilised in two of the hotels at Lucerne. A large installation on the same system has been put down in Rome, and several Continental cities are adopting this method of supplying electric light by small overhead wires. An advantage claimed by the Zippernowsky system is the method of keeping the strength of the magnetic field of the dynamos in accordance with the external demand for current. The regulating apparatus employed consists of a small transformer, the primary coil of which is traversed by the whole, or by a proportionate part, of the main circuit, while the secondary coil is inserted into the exciting circuit. Thus, if the main current increases, the exciting current induced in the two armature coils of the dynamo is reinforced by the inductive action of the regulating transformer; and the field of the dynamo is strengthened when more current is required. The opposite takes place when, through the extinction of lamps on the external circuit, the demand for current becomes less. In an experiment made with the transformers, which supply some five hundred electric lamps for the Teatro dal Verone and adjoining houses at Milan from the central electrical station three-quarters of a mile away, the main current was often found to vary from one ampère to thirty-five ampères; it was stated that no variation in the service pressure could be detected, and the lamps burnt with equal brightness whatever the number in use. In the experiments at the [Pg 35] Teatro dal Verone each transformer worked its own independent circuit of lamps; but, if the conditions of the different circuits were alike, they could be coupled up together in any manner desired, and thus a group of transformers could become a centre of distribution.

The alternating current system of the Westinghouse Company has come to the front in the United States with extraordinary rapidity, and, although it is not three years since the first plant was erected, at the present time over 190,000 incandescent lamps are operated from a number of central-stations. The fundamental principles of the Goulard system have been retained in the Westinghouse converter; but the manner in which these principles are applied has been greatly modified, while most of the details have undergone a radical change at the hands of the engineers and electricians whose researches have been utilised by the Westinghouse Company. The form of converter as now designed consists of a number of thin sheet-iron plates, shaped like the letter E, they are slipped alternately from opposite directions over the primary and secondary coils, which are disposed side by side; the inductive core is, therefore, composed of a mass of detached plates insulated from each other by paper, and forming a discontinuous magnetic circuit. In order to protect the converter from mechanical injury as well as dampness, and also to avoid the possibility of contact with wires [Pg 36] carrying currents of high potential, it is enclosed in a cast-iron case or box, made in two parts and adapted to be secured to any convenient support. Fig. 12 is a transverse vertical section of such a converter box, with the converter in position. The terminals of the primary coil, P, of the converter are led into the compartment D¹, and the terminals of the secondary coil into D². The terminals are secured to bolts or [Pg 37] couplings, f f, mounted upon insulating plates, e¹ and e². Fusible mica-foils, g, and switch plates, h and i, with plugs k, are provided for protecting and disconnecting the circuits. The open front of the compartments D¹ and D² are closed by glass plates, T, which permit inspection of the connections without entering the box. The converter box occupies little space, and may be placed in any convenient situation in or about the premises to be lighted, much the same as a gas-meter. The practice where overhead conductors are employed, is to mount the converter box on a pole in the vicinity of the premises to be lighted, as shown by Fig. 13, and thus it is only necessary to lead the secondary or low potential wires into the building, the high potential wires remaining in an accessible position upon the pole. Fig. 14 is a view of North Street, Pittsfield, [Pg 38] Massachusetts, engraved from a photograph, and shows a very neat form of tubular pole with its converter box on top. This arrangement is used throughout the city, and is a great improvement on the ordinary form of telegraph poles which so greatly disfigure American cities, and are really the most objectionable feature of the overhead wire system.

The potential ordinarily employed in the main circuits of the Westinghouse installations is about 1000 volts, and that in the lamp circuits 50 volts, the ratio of conversion, therefore, being as 20 to 1; the dynamos are manufactured, as a rule, in three sizes, No. 1 for 650, 16 candle-power lamps; Nos. 2 and 3 for respectively 1300 and 2500 lamps. The converters are also made in three ordinary sizes to supply 20, 30, and 40 lamps of 16 candle-power each. A 40-light converter contains about 85 pounds of iron and 25 pounds of copper, so that the total weight of metal is less than 3 pounds per lamp; the electrical efficiency of the converter is said to exceed 95 per cent. when the potential is reduced from 1000 volts in the primary to 50 in the secondary. “It is claimed that the trifling loss of energy in conversion from high to low potential at the point of consumption is made up for by gain at other points, especially in the increased efficiency of the lamps, so that an alternating current plant may be counted on to give 10-16 candle-power lamps per indicated horse-power, as against 7 with the direct system;” the comparative gain is doubtful, but by using 50 instead of 100 volts the life of the lamps is increased, the former having a much stronger filament and consequently a longer life. [Pg 39]

Having slightly diverged from the original lines by describing a system which is at present not introduced into Europe, a few remarks on the subject of electric motors may not be inappropriate, as they are almost universally worked in the United States, from the installation which supplies electric light. There is a considerable profit to the electric company if electric power is taken in the district, the wires conveying the lighting current are thus economically employed during the day. In the diagram, Fig. 15, which represents a district at Boston, the curve on the right principally represents the demand for power which takes place between the hours of 8 a.m. and 3 p.m. A circular was addressed to all the leading electric companies in America a short time ago, asking if they supplied power as well as light, also for what purposes it was used.

Answers were received from 56 companies, who stated that the motors were employed for:—driving ventilator fans, collar-and-cuff machines, printing-presses, various apparatus in repair-shops, sewing-machines, coffee-mills, gun-shop tools, sausage-machines, elevators, lathes, pumps, saws, ice-cream freezers, organ-bellows, and washing-machines. The size of motors varied from one-eighth to 15 horse-power; 26 companies have supplied motors from arc light circuits, 14 from arc and incandescent, and 16 from incandescent circuits alone. The motors are [Pg 40] principally owned by the subscribers, and are charged for at a rate varying from £3 to £15 per horse-power per month. The motor business is still in its infancy, but is cited to show how Electric Power can [Pg 41] supplant the steam-engine, especially for those purposes in which the power required is small and complete control is desirable.

It will be found, on examining Appendix II., that in European stations by far the larger number of lamps are maintained from installations employing the Edison system; the Ferranti plan of using transformers comes next, closely followed by Goulard and Zippernowsky; the distribution with secondary batteries follows, and the high-tension multiple series comes last.

The Edison system has frequently been discussed, in connection with [Pg 42] small installations, but in magnitude the stations in Berlin and in Milan exceed anything that has been started here with continuous current.

Before describing the central electric light station at the former city, it may be well to recall to mind that the Edison plan is the combination of a number of machines which pump electricity into a network of feeders, mains, and conductors, the lamps being placed in parallel circuit, as shown at L l, Fig. 16, and maintained at a constant potential of 110 volts.

M M′ are the flow and return mains, the dynamos bridging them across at one end. If the mains were very long, those near to the dynamos would be exhausting the supply, and the lamps at the remote end would not get the full pressure. A system of feeders has been devised so that each lamp, no matter where it may be, shall have approximately the full 110 volts working through it. Fig. 17 shows a long circuit consisting of two branch mains bridged by a large number of lamps, l l, and D D are [Pg 43] the dynamos at the central-station. Series of feeders, f f′, have to be taken from the dynamo mains and fed direct into the branch mains at various points, d d′, b b′, c c′, in order to distribute the electrical pressure equally.

The ordinary parallel system is undoubtedly suitable for small installations; but when the area to be lighted is extensive, it is impossible to proportion the mains, with a view to economy in the cost of copper, without sacrificing energy wasted in heating the conductors.

In Figs. 16, 17, the lamps are shown in simple parallel; but if two dynamos are connected together, and a main wire is run from each of their two extreme terminals and a third wire from the branch connecting the two machines, we have what is known as the three-wire system, which was invented by Edison in America, and Hopkinson in England, almost simultaneously. Although by using the third wire there is a saving in copper over the parallel plan, the maximum gain is not more than 25 per cent., under the best conditions; when the district to be illuminated is not more than 400 to 600 yards from the central-station, the three-wire system answers well, but as soon as this distance is exceeded the cost of the mains begins to mount up at a most alarming rate. Although there are many Edison installations in the United States on this system and a few on the Continent, it has only been used here in a few instances for factory lighting. [Pg 44]

The Santa Radegonda station at Milan is at the present moment the second largest Edison station in Europe. The building, which was formerly a theatre, is well adapted for the work required; the dynamos and engines are fixed in a deep basement, while the boilers are a few feet above the street level, the upper floors being used as stores and testing-rooms. The dynamos, eight in number, are of the old Edison type, with horizontal magnets; seven of these machines are connected to the feeders which supply the mains, and these cover the district to be lighted on the Edison network system. The motive power is furnished by six Armington-Sims, and two Porter-Allen engines, each connected direct to the armature of a dynamo, the speed being maintained at the uniform rate of 350 revolutions per minute, except in the case of the spare engine and dynamo, which is kept turning slowly, ready to be switched on should occasion demand. The starting or cutting-out of circuit of these large machines requires some care. In the first place, to start, it is necessary to insert resistance into the shunt circuit of the dynamo, which is done by a switch; but to throw 150 horse-power into the main circuit would be dangerous to the lamps, so that the current is first sent into a bank of one thousand lamps used as a resistance, and these are cut out step by step; similar care is taken when a machine is stopped. To control the electro-motive force, which varies greatly from time to time, hand regulation is used during the day, with [Pg 45] the help of the Edison tell-tale, consisting of two lamps, a red and white one, which light up when the current is high or low; but when the night service comes on, as it may happen that two thousand lamps may be turned out at once, an attendant has to carefully watch the electric regulator, and be ready to insert resistance into the field-magnet circuits by moving a wheel connected by a shaft and bevel-gear to a system of commutators. The principal difficulty to be overcome, in an installation where the current is distributed over a large area, is the regulation of the electro-motive force at the various points, as at Milan; there are no return galvanometer wires, which are now used in both the two and the three-wire Edison systems in the United States. The plan devised by the company’s electrician at Milan is very ingenious, and enables the pressure at the ends of the various feeders to be kept practically the same, although they are of different lengths and sectional area. In the first place, resistance was added to each feeder to equalise the resistance in each conductor; and, in order to provide for the varying amount of current the feeder has to supply, a peculiar form of commutator, having a guillotine-shaped contact-piece, was inserted in the circuit. By moving this, suitable resistance is inserted or cut out, and the attendant, having a series of numbers, has only to set this instrument to the number shown by the ampère meter. By far the largest amount of current is drawn off for the lighting of the Scala Theatre, the stage-lighting alone taking more than one thousand lights: if these were all turned on suddenly, the other lights in the district would be dimmed; to obviate this, auxiliary feeders have been [Pg 46] run, which are used only when any great increase is expected; commutators similar to those referred to above also regulate these feeders without any special attention. The pressure at any point in the system is by this means easily controlled, and affords an illustration of what is perhaps not the most economical, but is found to be the most practicable, way of maintaining a constant potential in a district where the amount of output of current is suddenly doubled. Fig. 18 is a [Pg 47] plan of the network system of conductors laid through a large portion of the city; the conductors are in outward appearance similar to gas-pipes, the current passing through semicircular bars of copper, embedded both for the flow and return in the same iron tube, which is laid underground in a shallow trench. The house-supply is drawn from the mains, and these are connected to the feeders by means of ordinary junction-boxes, which each contain a fusible cut-out. The bridge-boxes allow of expansion of the line, and have connections for testing purposes. The insulation is extremely good, mainly on account of the favourable nature of the ground, which is chiefly gravel; no trouble has been experienced with leakage, nor has the service ever been interrupted. The cut-outs are of an improved Edison form, but have the disadvantage attending all lead plugs where the current is great, in that, to guard against accidental melting due to the heating effect of the current, the sectional area of the lead has to be much larger than would be otherwise necessary. In fact, these cut-outs will protect the cable against a bad short circuit, but nothing else.

In addition to the glow lamps, eighty arc lamps are worked in derivation, two in series; most of these lamps require 45 volts, to which 10 per cent. of idle resistance is added, constituting a total loss of current which is extremely low for a combined arc and incandescent system of lighting. The service commenced in 1882 with a little over one hundred lamps, and at present there are over ten thousand glow lamps, and two hundred arc lamps are in use. At first the [Pg 48] new enterprise had to struggle against very great difficulties; not only the technical difficulties of distribution by means of a network of feeders and mains had to be overcome, but also those arising from the prejudices of consumers and the competition of the gas company, who tried to deter consumers from introducing electric light into their houses. One of these means consisted in offering to the private consumers, resident in the district which was threatened by competition with electricity, an agreement by which the gas company bound itself to supply gas at 5s. 8½d. per 1000 cubic feet, instead of 7s. 7d. as charged hitherto; and even now those inside the “charmed circle” of the electric light conductors get their gas cheaper than the public outside. One of the reasons which accelerated the adoption of electric light was the introduction of the Edison meter, in consequence of which consumers could be charged exactly for the amount of light they had received, and were relieved from paying a lump sum according to the number of lamps fixed, which was customary in the early days of the company. The prices at which the company now provides light, at all hours of the day and night, are as under:—

| Type of Lamp. |

Installation charge per lamp. |

Charge per lamp·hour. |

|

|---|---|---|---|

| s. | d. | ||

| 10- | candle | 18 | 0·26 |

| 16- | ” | 28 | 0·40 |

| 32- | ” | 56 | 0·80 |

that is, a little over ½d. per ampère-hour; the 10-candle lamps requiring 0·5, the 16-candle lamps 0·75, and the 32-candle lamps 1·5 ampère. [Pg 49]

The company lends meters for 50, 100, and 150 lamps, at an annual rent of 4s. 10d., 7s. 3d., and 9s. 7d. respectively, and replaces, without charge to the consumer, any lamp the filament of which has broken, but it does not replace lamps where the glass is broken. For arc lamps requiring 9 to 10 ampères, an annual rent of £2 must be paid for the lamp itself, and a charge of a little over ½d. per hour for every ampère-hour. The carbons are charged for at 1d. per pair, lasting for about seven hours. Now that the installation has been in use for several years, and that the company has arrived at a very accurate estimate of the time during which an average consumer requires the light—about one thousand six hundred lamp-hours per annum—it proposes to simplify the method of charging large consumers, by omitting the initial charge of each lamp, and, instead, to charge 0·6d. for each 16-candle lamp-hour.

The Edison meters are based on the electrolytic action of a small fraction of the current which passes through the meter. They are cells, with rectangular zinc plates immersed in a solution of sulphate of zinc of 1·054 density, the distance between the plates being a little over ¼ inch. The proportion of the current which passes through the meter to that which passes directly into the consumer’s house is 1 to 973. The resistance of the shunt circuit is 9·75 ohms, made up as follows: cell, 1·75 ohm; metallic portion, 8 ohms. The resistance of the metallic portion rises with the temperature, whereas that of the cells falls with a rising temperature; and in this manner the small variations of [Pg 50] resistance which might take place in the cell are counter-balanced by the equally small variations in the resistance of the metallic portion. A complete meter consists of two similar-sized cells of the same resistance, placed in series. The object of employing two cells is, that when little current is passing, as in the summer months, one cell alone is used, and when the consumption is sufficiently large both cells are employed, and the mean between the two indications is taken as the basis for calculation in number of ampère-hours. The quantity of electricity passed through the cell is calculated by the loss of weight which has taken place in the positive plate. An employé of the society visits every meter monthly, taking away the old cells and substituting others freshly constructed. A book is kept in which the weights of the new plates and those of the returned plates are entered, and on the basis of these entries the accounts are made up. The largest plates are those in the 100-light meter, and are intended for a maximum current of 75 ampères in the main circuit; they are 6 inches long by 2 inches wide. In cases where a larger amount of current is taken, the capacity of the 100-light meter is increased by joining two or more copper strips across the terminals of the cells. The weak point of the system is the removal of the cells, which leaves the adjustment of the account to be paid entirely in the hands of the Electric-Light Company; in spite of this drawback, it is stated that there has not been a single complaint from consumers during the four years in which the meter system has been in use. [Pg 51]

It is evident that in so extensive a system of lighting a short circuit now and then between the lamp wires and the earth cannot altogether be avoided. Many of the lamps have been fitted to existing gas fittings, and are beyond the daily supervision of the company’s officers; the faulty place is often not easily accessible, so the first step taken is to discover on which of the two circuits the trouble has occurred. This is done at the station by joining two 16-candle lamps in series across the main conductors and the point of junction between the two lamps is connected to earth by a stout wire. As long as both circuits (positive and negative) are perfectly insulated from earth no current flows through this middle wire, and both lamps remain hardly incandescent; but, if one of the circuits should be in connection with the earth, the lamp which is joined on the other circuit will brighten up, because the potential of the middle wire and that of the faulty circuit are both zero, and consequently the lamp between the middle wire and the sound circuit receives the full pressure of 110 volts. To localise the fault, contact is made between the earth and the sound circuit by means of a fusible plug of known melting point, say for a thirty-lamp supply. If the fault is on a portion of the external circuit, supplying less than thirty lamps, its fusible plug will melt as soon as the sound main is put to earth. If, however, the fault is on a portion supplying more than thirty lamps, the fusible plug which has been inserted at the [Pg 52] station between the sound main and the earth will melt instead. A series of fusible plugs are thus tried, increasing in melting capacity until one is found that does not go: in this case, the other plug on the faulty portion has melted, and the consumer’s lamps on that branch are extinguished; the position of the fault is thus localised, and the company proceed to remedy the defect without interfering in the slightest degree with the rest of their system.

The Edison system is also employed at Berlin, in fact the Deutscher Edison Gesellschaft have at the present time a monopoly of the supply of the city from three large central-stations, each of which serves the area in their immediate neighbourhood. The mains differ from those used at Milan in that stranded highly insulated cables, protected with steel wire on the outside, are laid under the pavement in every street throughout the district. With the exception of the Leipziger strasse and Unter den Linden, which are lit with arc lamps suspended from chains running between cast-iron poles 24 ft. high, about 100 to 250 ft. apart, gas is used for the street lighting, and electricity for the interior illumination of many public buildings and private houses; there are also a good many arc lights outside the shops and restaurants. The mains are on the Edison network system, the area of copper being such, that when all the lamps are on there is a loss of [Pg 53] energy of 25 per cent.; but this does not occur on an average for more than half an hour a day. No sole concession is given to the company, who simply have the right to take up the pavement and cross streets, and for this permission they are bound to furnish any consumer in the district with a constant supply of electricity at the following charges:—

| 10- | candle lamps | 2·5 pf., | about | 0·29 d. | per hour. |

| 16- | ” | 4·0 | ” | 0·48 | ” |

| 32- | ” | 8·0 | ” | 0·96 | ” |

| 50- | ” | 12·5 | ” | 1·50 | ” |

| 100- | ” | 25 | ” | 3·00 | ” |

In addition to this an installation fee of 6s. per lamp is charged, which includes one lamp.

Meters are charged as follows:—

| £ | s. | d. | ||||

| 10- | to 16- | candle-power | 0 | 16 | 0 | per annum. |

| 25- | ” | 1 | 0 | 0 | ” | |

| 50- | ” | 1 | 10 | 0 | ” | |

| 100- | ” | 2 | 0 | 0 | ” | |

A discount is allowed off this meter charge, varying with the number of hours the light is used in the year.

The cost of gas is about 4s. 9d. per 1,000 cubic feet, so the electric light is slightly the dearer illuminant.

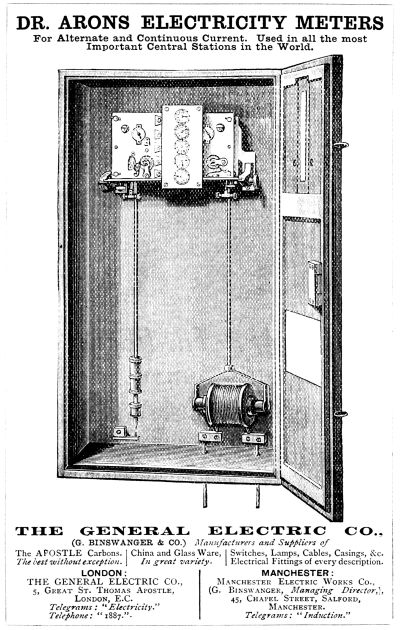

The Aron meter, Fig. 19, is usually employed as the recorder of the electricity consumed. It consists of two pendulums, controlling two distinct clockwork gears. One oscillates at a regular speed, but the other has a permanent magnet, instead of a weight, and is variable in [Pg 54] speed. The entire current passes through the solenoid, which is underneath the pendulum, with the magnet; the difference in speed [Pg 55] between the standard and variable clocks is given in direct ampère-hours by a counter-gearing similar to the index of a gas-meter. An electro-magnet starts each pendulum when the current begins to flow, and immediately it ceases, two detents come into operation and hold the pendulums stationary.

This method dates back to the introduction of the incandescent light, and, although it has been frequently demonstrated that a small current of high potential could be employed to work incandescent lamps, the series system has never been installed on a commercial scale, and is confined to arc lighting. In the United States the usual pressure for arc lighting is 2,000 volts, and it is not an uncommon occurrence to have forty arc lamps in series upon a line over 10 miles in length, carrying a current of 10 ampères. To economically use this high pressure for glow lamps in series, they must be of such design as to enable the whole of the current to be passed through them without injury. The filament of an ordinary high-resistance glow lamp would be immediately destroyed, so that low-resistance lamps, having a much larger sectional area, must be employed. The Bernstein or the Cruto lamp, which can be made to have a “hot” resistance of about 0·7 ohm, [Pg 56] and requires a current of 9·75 ampères, could be used, and the current might be economically brought from a great distance. Mr. Bernstein calculates that it would be possible to operate 6,000 of these 7-volt lamps from twenty dynamos, each giving a current of 10 ampères at a potential of 2,000 volts, and still have a margin for loss of current in the leads. An economical feature of this scheme is the easy way in which power could be saved when only comparatively few lights were required; for instance, in the daytime all the circuits could be looped together and fed by one dynamo, and, as the number of lights increased, so other machines could be switched in by having an auxiliary bank of lamps as a resistance. From the central-station twenty pairs of carefully insulated copper wires, say of No. 6 B. W. G., would lead to the houses; and, as a good-sized ordinary house takes on an average twenty lights, the conductor would pass through fifteen houses before it returned to the station. It is in the house that the practical difficulty commences, as in this series system the circuit must never be opened, so that the switches and safety appliances must be such that, whatever happens, there must remain some path for the current, otherwise all the lights on that particular circuit would be extinguished. Mr. Bernstein gives the designation of “short closed” if the current goes through the switch-lever, and “long closed” if the current is led through the lamps or other electrical devices.

Fig. 20 is a diagram of the lamps in any building. The street main, M, [Pg 57] enters at the main switch, S, and continues from switch to switch, S¹ S¹, and returns to S before it leaves. It is necessary, to guard against any possible extinction, to construct all the switches so that it would be impossible to move the lever without a lamp was lighted; and, should the lamp give out, an equivalent resistance must be automatically inserted. These details have been investigated by Mr. Alexander Bernstein, who has designed a complete system for “series” lighting, and claims for it special economical advantages. It is, however, very doubtful if this plan can be recommended for adoption in private houses; but in public lighting, or in large establishments where an electrician could be kept to look after the fittings and the insulation of the conductors, there should be no more danger, in introducing the high-tension continuous current of 2,000 volts, than [Pg 58] there is at present with the 100-volt alternating current, and the relative saving in weight of conductors would be an important item.

Installations on this method have been erected at Messrs. Brunner and Mond’s alkali works, and in several large factories in the United States where lights had to be distributed over a considerable area; the system has not, however, come into favour for central-station work.